Repair – John Deere stx38 User Manual

Page 225

3/20/97

5 - 61

POWER TRAIN

REPAIR

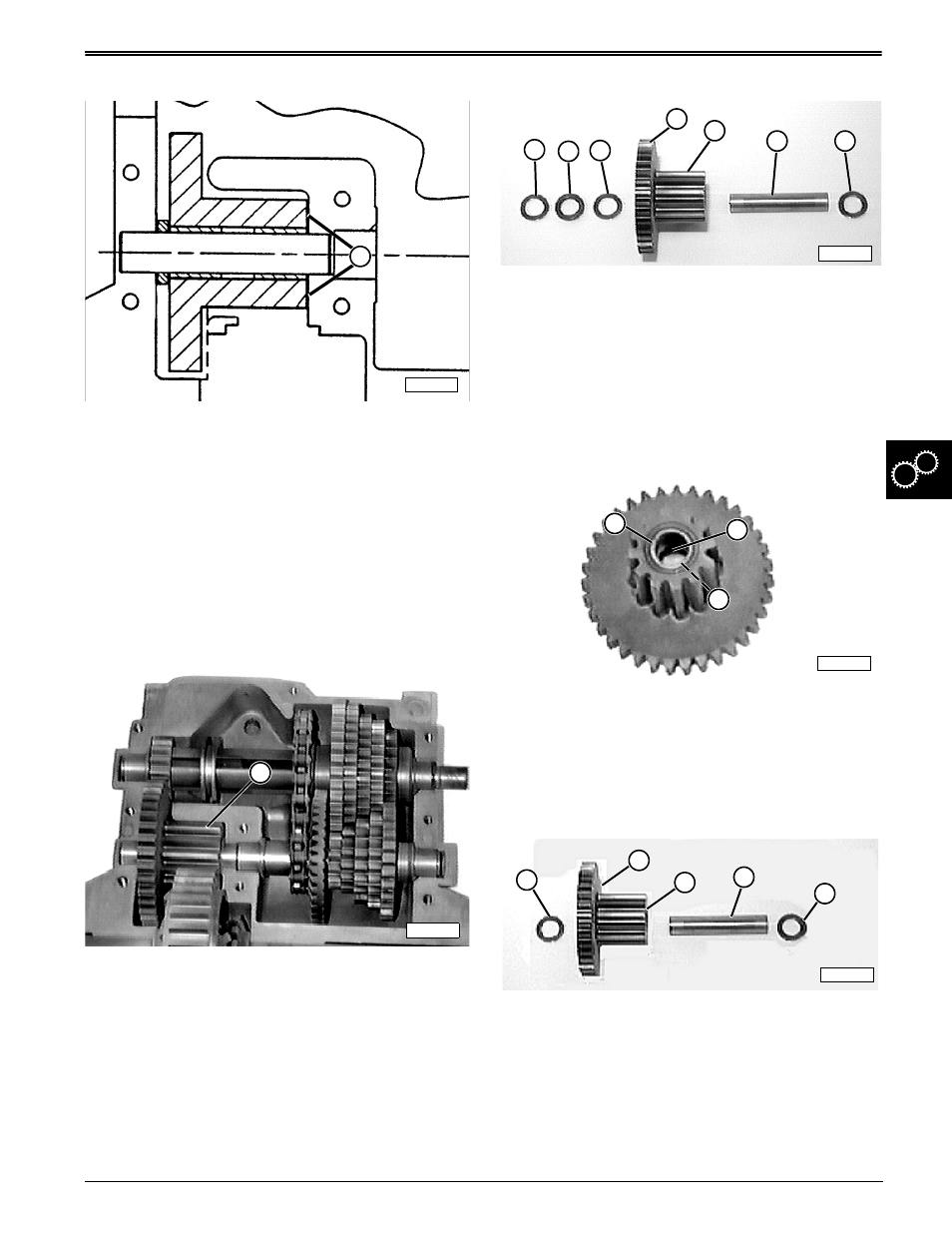

Inspect Idler Combination Gear Assembly:

1. Visually check overall condition of assembly,

including shaft and bushings, gears for wear,

pitting, broken teeth, etc.

2. Use a feeler gauge to measure “go/no go” air gap

(A) between end surface of combination gear and

side surface of case half:

• “GO” air gap should be 0.33—0.63 mm (0.013 —

0.025 in.)

• “NO GO” air gap is anything greater.

3. If measurement results in a “NO GO” reading, worn

and damages components need to be replaced.

Disassemble Idler Combination Gear Assembly:

1. Lift idler combination gear assembly (A) from lower

case half.

2. Clean components individually once disassembled.

STX38 (SN 210001—301382) and STX46 Transaxle

3. Separate and inspect assembly components:

• washers (B and D) should be 0.632 x 1.00 x 0.026

in., not scored or discolored (burnt)

• spacer (C) should be 0.630 x 1.00 x 0.169 in., not

scored or discolored (burnt)

• narrow combination gear (E) should have 35 good

teeth and wide combination gear (F) should have

12 good teeth, not scored or discolored (burnt)

• idler shaft (G) should be smooth and not scored,

pitted, or discolored (burnt)

• shim washer(s) (H) are found in Shim Kit.

• inside bearing (I) and outside (K), which are press

fit, should not be scored nor discolored (burnt);

• gear bore (J) should not be scored or discolored

(burnt). Replacement gear has needle bearings

(with special grease) and a new shaft is also

recommended whenever a new gear is ordered.

STX38 (SN 301383— ) Transaxle

4. Separate and inspect assembly components:

• washers (B) should be 0.632 x 1.00 x 0.026 in., not

scored or discolored (burnt)

• narrow combination gear (C) should have 30 good

teeth and wide combination gear (D) should have

12 good teeth, not scored or discolored (burnt)

• idler shaft (G) should be smooth and not scored,

pitted, or discolored (burnt)

• shim washer (F) is found in Shim Kit

M42523

A

A

M42324

M42325

B

C

D

E

F

G

H

M42326

I

K

J

M88996

B

C

D

E

F