John Deere stx38 User Manual

Page 228

5 - 64

3/20/97

REPAIR

POWER TRAIN

TRANSAXLE ASSEMBLY—

STX38 (SN 210001— ) & STX46

NOTE: STX38 (SN 301383— ) transaxle differs

slightly from STX38 (SN 210001—301382)

and STX46 transaxle.

IMPORTANT: Coat lightly all mating surfaces,

except seal surfaces, with SAE 30 weight oil

before assembly. Pay close attention to proper

order and orientation of all components. Also, it

is recommended that you use a calliper to

ensure the correct shim, spacer, or washers are

installed correctly.

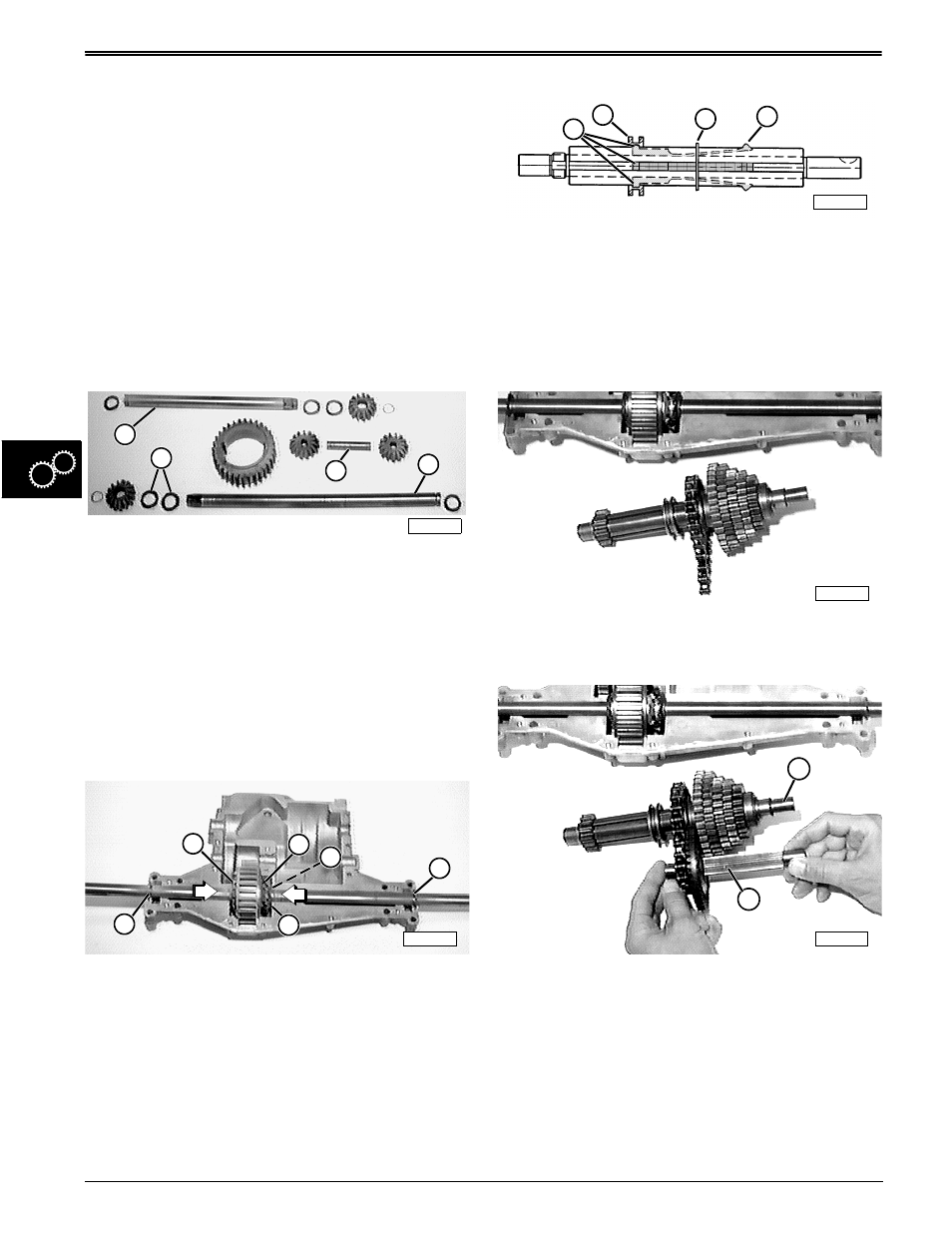

Assemble Differential/Axle Shafts Assembly:

1. Assemble left-hand, short axle (A) as shown with

splined, beveled gear facing the ring gear.

2. Assemble right-hand, long axle (D) as shown with

splined, beveled gear facing the ring gear and

shim washers (B) assembled in combination of

thicknesses to obtain specified air gap (see

Inspect Differential/Axle Shafts Assembly).

3. Assemble internal shaft (C) as shown with beveled

gears facing each other.

4. Install internal shaft assembly in slots of ring gear

and push beveled gears away from each other so

they are ready to mesh with both axle beveled

gears.

5. Install axle shafts so beveled gears (E) mesh with

differential internal shaft beveled gears.

6. Keep inward pressure on both axles as you install

differential assembly in lower case housing.

7. Measure air gap between shim washers (F) and

side of housing (H). If air gap meets specification

(see Inspect Differential/Axle Shafts Assembly), go

to next step. If air gap does not meet specification,

remove right axle shaft and add other shim washer

combinations until air gap in within specification.

8. Carefully install new axle shaft seals (G and I) and

seat them in their lower case housing grooves.

Assemble Drive/Intermediate Shaft Assemblies:

1. Install retaining ring (C) in intermediate shaft

groove.

2. Install four keys in grooves of intermediate shaft

and hold them so internal shift collar anchors (A)

will seat in internal groove of collar (B) as it is

installed on the shaft.

3. Slide shift collar and keys against retaining ring (C)

and compress locking ramps/lugs (D) to clear

retaining ring.

4. Install remaining intermediate shaft components in

their proper order and orientation (reference top

two rows of components in photo on opposite

page).

5. Install drive shaft components one at a time from

left-to-right (reference bottom row of components

in photo on opposite page). Long flange of small

sprocket (J) faces bevel drive gear.

6. Shim washer(s) (E) for intermediate shaft (F) are

found in Shim Kit.

7. Shim washer(s) (H) for drive shaft (I) are found in

Shim Kit.

8. Install new intermediate shaft seal (G) with open lip

facing inside.

M42493

C

B

D

A

M42492

E

E

G

F

H

I

M42526

B

C

D

A

M42498

M42499

F

I