Shift linkage adjustment – John Deere stx38 User Manual

Page 201

3/21/97

5 - 37

POWER TRAIN

TESTS AND ADJUSTMENTS

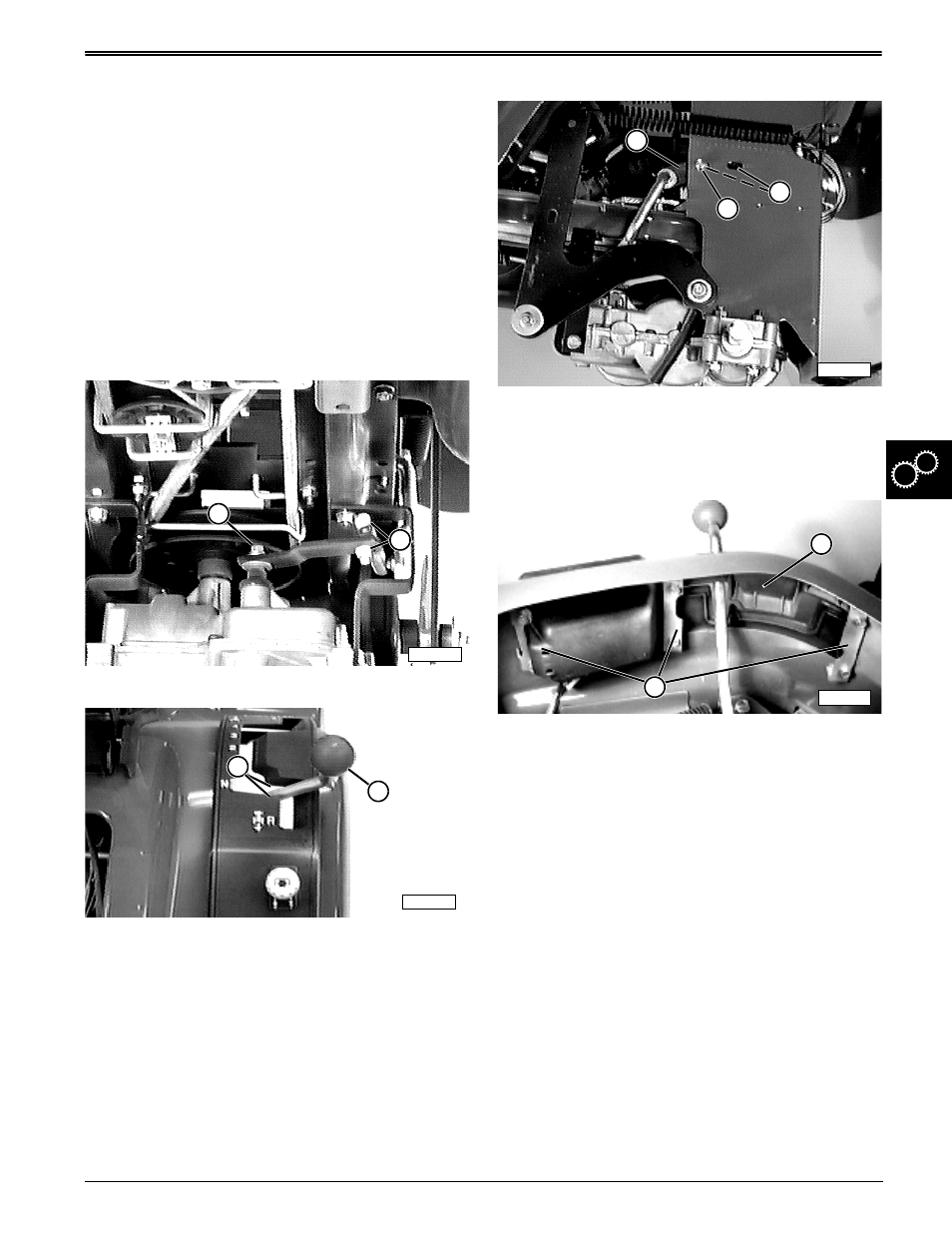

SHIFT LINKAGE ADJUSTMENT

Reason:

To ensure shift lever obtains all shift positions and that

neutral position does not allow transaxle to creep.

Conditions:

• Safely raise rear wheels 51 mm (2 in.) off surface

and block front wheels (front and rear).

• Shift lever in neutral.

• Park brake off.

Procedure:

1. Check that shift linkage hardware (A and B) is in

good condition and tight.

2. Start and run engine at fast idle.

3. Check that transaxle does not creep (axle rotation

while shift lever is in neutral position and clutch/

brake pedal released).

4. If transaxle creeps, move shift lever (D) slightly

inside neutral slot (C) of shift quadrant until creep

motion stops.

5. If shift lever is moved and creep motion does not

stop, turn engine off and loosen left side lock nut

(E) (left wheel removed for clarity purposes only).

6. Start and run engine at fast idle while you slide left

side bracket (F) forward or rearward in slots (G)

until creep motion stops. Tighten nut.

7. If left side bracket adjustment (Step #6) does not

stop creep motion and shift quadrant (H) does not

allow enough shift lever movement to stop creep

motion, loosen three mounting brackets (I).

8. Adjust quadrant forward or rearward until transaxle

does not creep with shift lever in the center of the

neutral position and clutch/brake pedal released.

9. Stop engine, hold quadrant in place, and tighten

three mounting brackets (I).

10. Lower tractor to surface and remove blocks.

Results:

• Test drive tractor to ensure all forward and reverse

gears are obtained and that transaxle does not

creep in neutral position.

• If adjustments are not satisfactory, repeat

procedure until proper results are obtained.

• If adjustments are still not satisfactory, internal

transaxle repair is needed.

M42590

A

B

M55808

D

C

M42535

E

F

G

M55803

I

H