O-ring face seal fittings, O-ring boss fittings – John Deere stx38 User Manual

Page 19

3/20/97

2 - 11

SPECIFICATIONS AND INFORMATION

O-RING SEAL SERVICE RECOMMENDATIONS

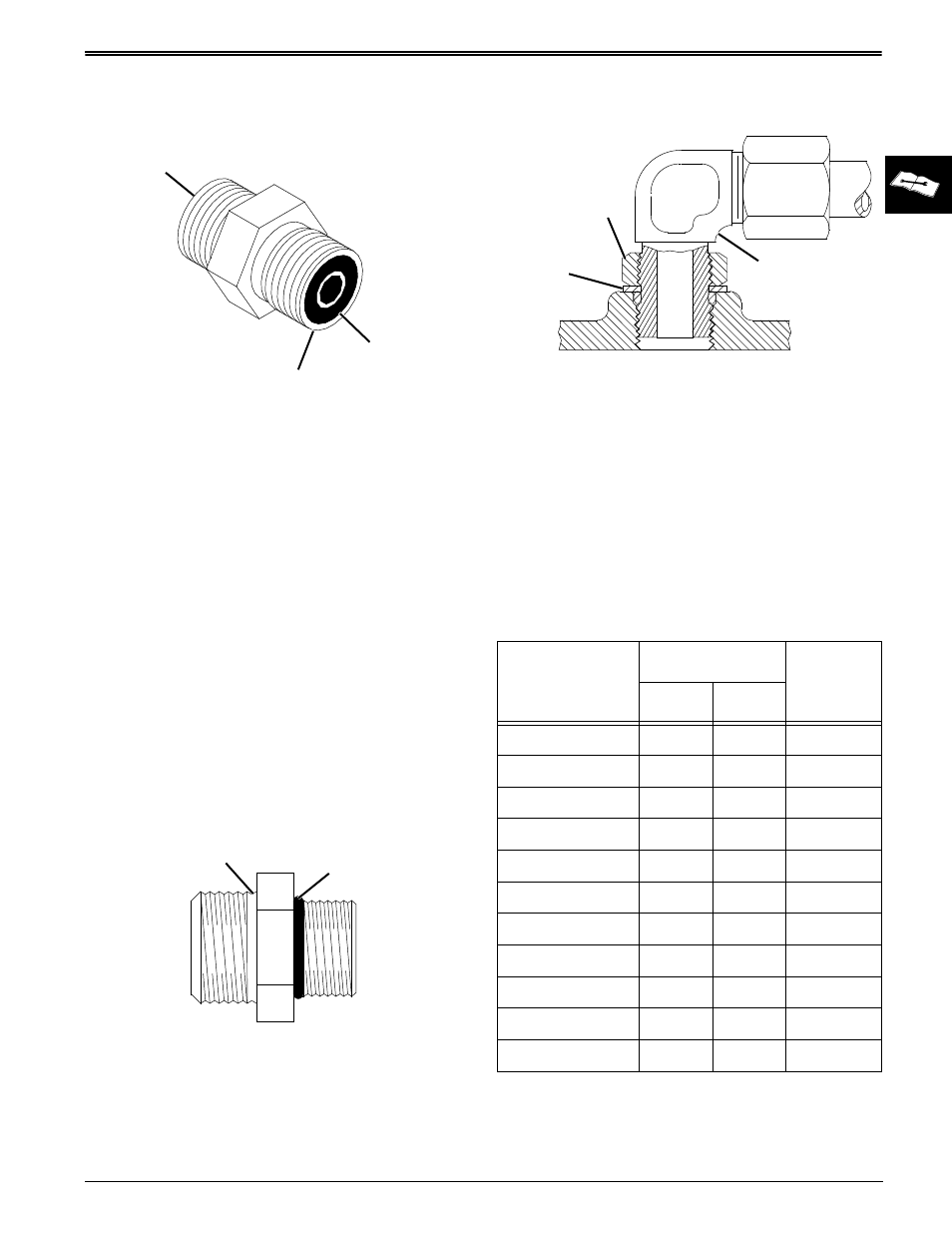

O-RING FACE SEAL FITTINGS

1. Inspect the fitting sealing surfaces. They must be

free of dirt or defects.

2. Inspect the O-ring. It must be free of damage or

defects.

3. Lubricate O-rings and install into groove using

petroleum jelly to hold in place.

4. Push O-ring into the groove with plenty of

petroleum jelly so O-ring is not displaced during

assembly.

5. Index angle fittings and tighten by hand pressing

joint together to insure O-ring remains in place.

6. Tighten fitting or nut to torque value shown on the

chart per dash size stamped on the fitting. Do not

allow hoses to twist when tightening fittings.

O-RING BOSS FITTINGS

1. Inspect boss O-ring boss seat. It must be free of dirt

and defects. If repeated leaks occur, inspect for

defects with a magnifying glass. Some raised

defects can be removed with a slip stone.

2. Put hydraulic oil or petroleum jelly on the O-ring.

Place electrical tape over the threads to protect O-

ring from nicks. Slide O-ring over the tape and into

the groove of fitting. Remove tape.

.

3. For angle fittings, loosen special nut and push

special washer against threads so O-ring can be

installed into the groove of fitting.

4. Turn fitting into the boss by hand until special

washer or washer face (straight fitting) contacts

boss face and O-ring is squeezed into its seat.

5. To position angle fittings, turn the fitting counter-

clockwise a maximum of one turn.

6. Tighten straight fittings to torque value shown on

chart. For angle fittings, tighten the special nut to

value shown in the chart while holding body of

fitting with a wrench.

a. Torque tolerance is ± 10 percent.

b. To be used if a torque wrench cannot be used.

After tightening fitting by hand, put a mark on nut or

boss; then tighten special nut or straight fitting the

number of flats shown.

Sealing Surface

O-ring

Sealing Surface

Groove

O-ring

STRAIGHT FITTING OR SPECIAL NUT TORQUE

Thread

Size

Torque

a

Number

of Flats

b

N•m

lb-ft

3/8-24 UNF

8

(6)

2

7/16-20 UNF

12

(9)

2

1/2-20 UNF

16

(12)

2

9/16-18 UNF

24

(18)

2

3/4-16 UNF

46

(34)

2

7/8-14 UNF

62

(46)

1-1/2

1-1/16-12 UN

102

(75)

1

1-3/16-12 UN

122

(90)

1

1-5/16-12 UN

142

(105)

3/4

1-5/8-12 UN

190

(140)

3/4

1-7/8-12 UN

217

(160)

1/2

Special Nut

Special Washer

Angle Fitting