ADS Environmental Services Portable FlowShark Pulse QR 775006 A2 User Manual

Page 55

3-18 ADS Portable FlowShark Pulse Manual

accommodate the sensor shaft. ADS recommends using a 1.5-inch (38-mm) diameter

steel rod to test for interference to ensure the sensor shaft will fit into the pipe.

For assistance when installing the sensor taps or fittings, please contact the pipe

manufacturer or a professional pipe fitter.

Risk of accident!

Always use a mobile safety circuit breaker when working in a wet

environment and/or drilling into full pipes!

Please ensure the turnings can easily escape while drilling.

Interrupt drilling as necessary to remove turnings before

proceeding. Remove burrs with a file once drilling is complete to

prevent measurement errors.

Never burn pipes with welding torches!

A burn in a weld seam may cause swirls and, therefore, result in

measurement errors.

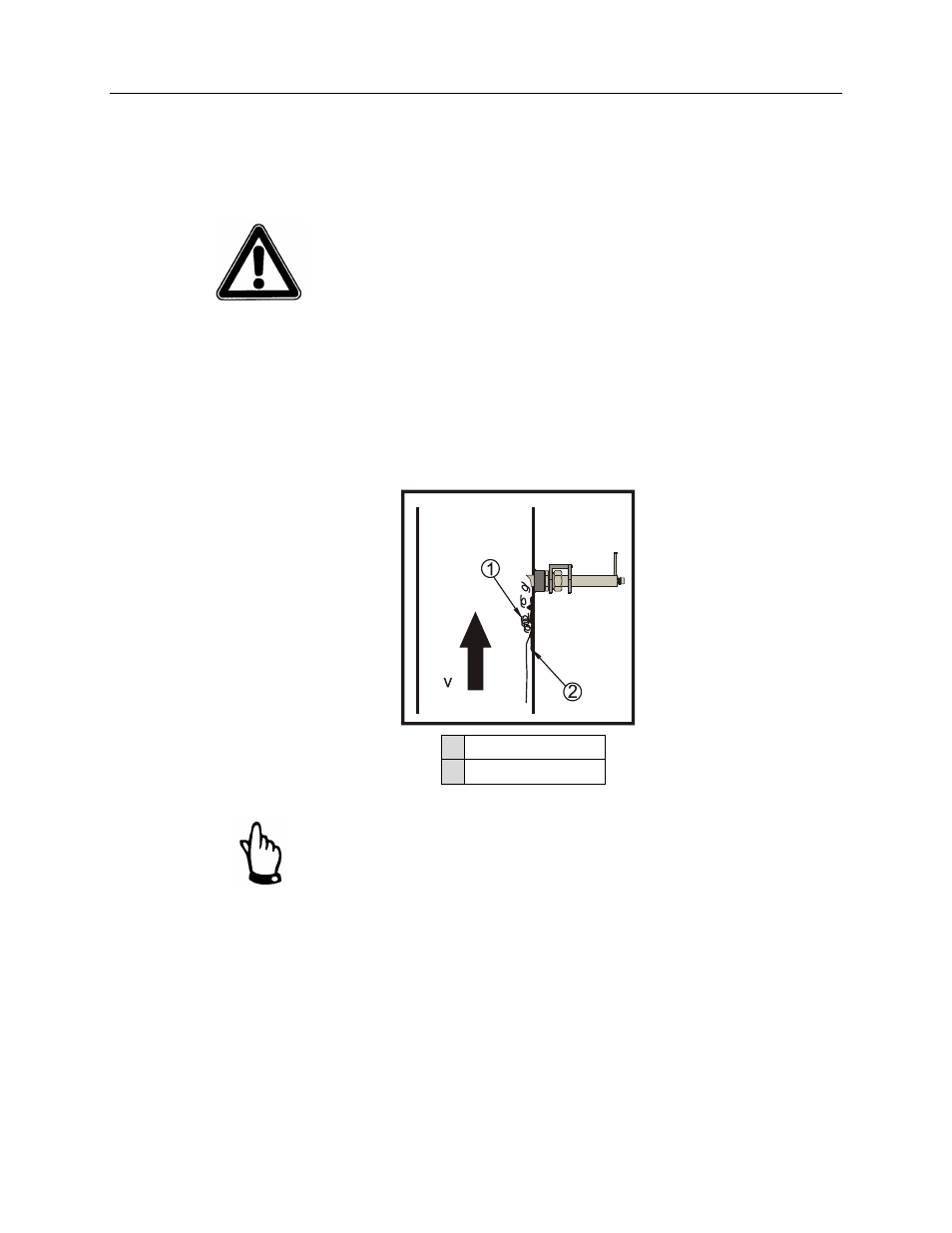

1

Whirls/chips

2

Weld seam burn

Disturbances and measurement errors caused by weld seam burn

When assembling the pipe insertion sensor, use a special grease for

the stainless steel couplings (DIN 2353, or equivalent). Apply a

small amount of grease to the cap nut thread, threads, cone, and

cutting ring when pre-assembling the insertion sensor. The screw

joints come pre-greased from the manufacturer. Purchase

additional grease through ADS, when necessary.