Aluminum, 400a bevel cut, H17 plasma / n₂ shield – Tweco Ultra-Cut Torch Data User Manual

Page 78: This art is for reference only

TORCH DATA for Ultra-Cut

8-78

Manual 0-4828

Rev BA

Aluminum

Flow Rates (SLPM / SCFH)

400A Bevel Cut

H17

N₂

Preflow

- / -

207 / 439

H17 Plasma / N₂ Shield

Cutflow

47 / 100

173 / 367

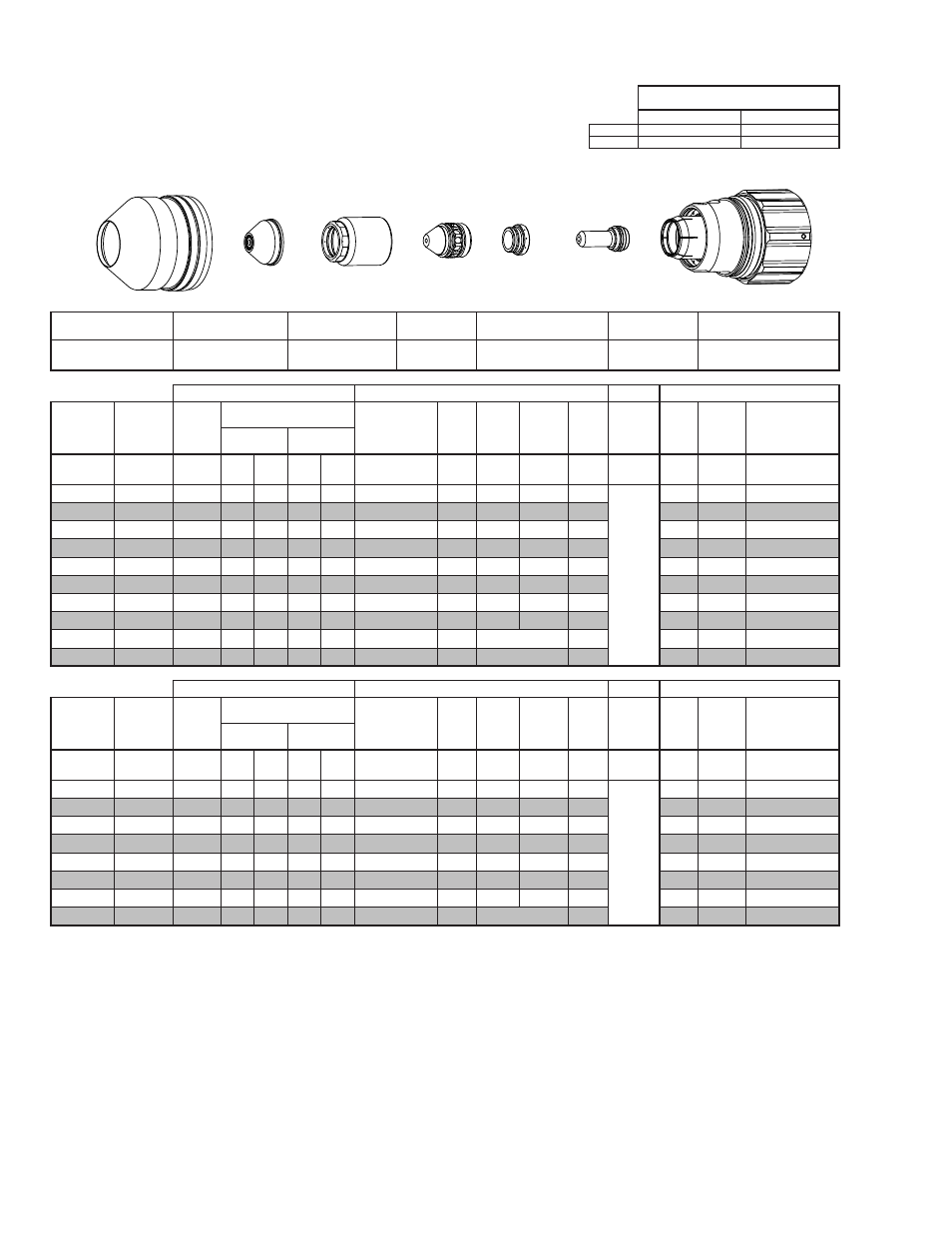

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas Distributor

Electrode

Cartridge

21-1305

≤ 1” / 25 mm 21-1304

> 1” / 25 mm 21-1307

21-1303

21-1302

21-1306

21-1301

21-1300

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Effective

Material

Thickness

Min.

Clearance

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Effective Cut

Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (H17) Shield (N₂)

inch

(in)

(psi)

Ball (psi) Ball (psi)

(in)

(sec)

(in)

(in)

(sec)

(in)

(ipm)

(sec)

(in)

0.500

0.080

30

120 100 NA 100 0.200 - 0.600 0.3

0.350 0.250

0.4

N

ot R

ec

omme

nded without

Ele

va

tion He

igh

t

200

0.4

0.195

0.625

0.080

30

120 100 NA 100 0.200 - 0.600 0.3

0.350 0.250

0.4

180

0.3

0.200

0.750

0.080

30

120 100 NA 100 0.200 - 0.600 0.6

0.350 0.250

0.4

150

0.4

0.200

1.000

0.080

30

120 100 NA 100 0.350 - 0.600 0.7

0.350 0.250

0.4

100

0.5

0.230

1.250

0.080

30

120 100 NA 100 0.350 - 0.600 0.8

0.350 0.300

0.4

80

0.6

0.230

1.500

0.080

30

120 100 NA 100 0.350 - 0.600 1.4

0.350 0.300

0.4

60

1.2

0.240

1.750

0.080

30

120 100 NA 100 0.400 - 0.600 3.0

0.350 0.500

0.4

45

2.0

0.275

2.000

0.080

30

120 100 NA 100 0.400 - 0.600 5.5

0.350 0.700

0.4

35

4.5

0.285

2.250

0.080

30

120 100 NA 100 0.400 - 0.600 2.0

Edge Start

0.4

20

2.0

0.310

2.500

0.080

30

120 100 NA 100 0.400 - 0.600 3.0

Edge Start

0.4

10

3.0

0.325

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Effective

Material

Thickness

Min.

Clearance

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Effective Cut

Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (H17) Shield (N₂)

(mm)

(mm)

(Bar)

Ball (Bar) Ball (Bar)

(mm)

(sec)

(mm)

(mm)

(sec)

(mm)

(mm/

min)

(sec)

(mm)

15

2.0

2.1

120 6.9

NA

6.9

5.1 - 15.2

0.3

8.9

6.4

0.4

N

ot R

ec

omme

nded

without Ele

va

tion Heigh

t

4710

0.3

5.0

20

2.0

2.1

120 6.9

NA

6.9

5.7 - 15.2

0.6

8.9

6.4

0.4

3620

0.4

5.2

25

2.0

2.1

120 6.9

NA

6.9

8.7 - 15.2

0.7

8.9

6.4

0.4

2620

0.5

5.8

30

2.0

2.1

120 6.9

NA

6.9

8.9 - 15.2

0.8

8.9

7.3

0.4

2170

0.6

5.8

35

2.0

2.1

120 6.9

NA

6.9

8.9 - 15.2

1.1

8.9

7.6

0.4

1770

0.9

6.0

40

2.0

2.1

120 6.9

NA

6.9

9.3 - 15.2

1.9

8.9

9.1

0.4

1410

1.4

6.4

50

2.0

2.1

120 6.9

NA

6.9

10.2 - 15.2

5.2

8.9

17.1

0.4

920

4.2

7.2

60

2.0

2.1

120 6.9

NA 6.9

10.2 - 15.2

2.4

Edge Start

0.4

390

2.4

8.0

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Gas

Distributor

Electrode

Cartridge Assembly

This Art Is For Reference Only

Art# A-10444