Aluminum, 200a, H35 plasma / n₂ shield – Tweco Ultra-Cut Torch Data User Manual

Page 41: This art is for reference only

Manual 0-4828

Rev BA 8-41

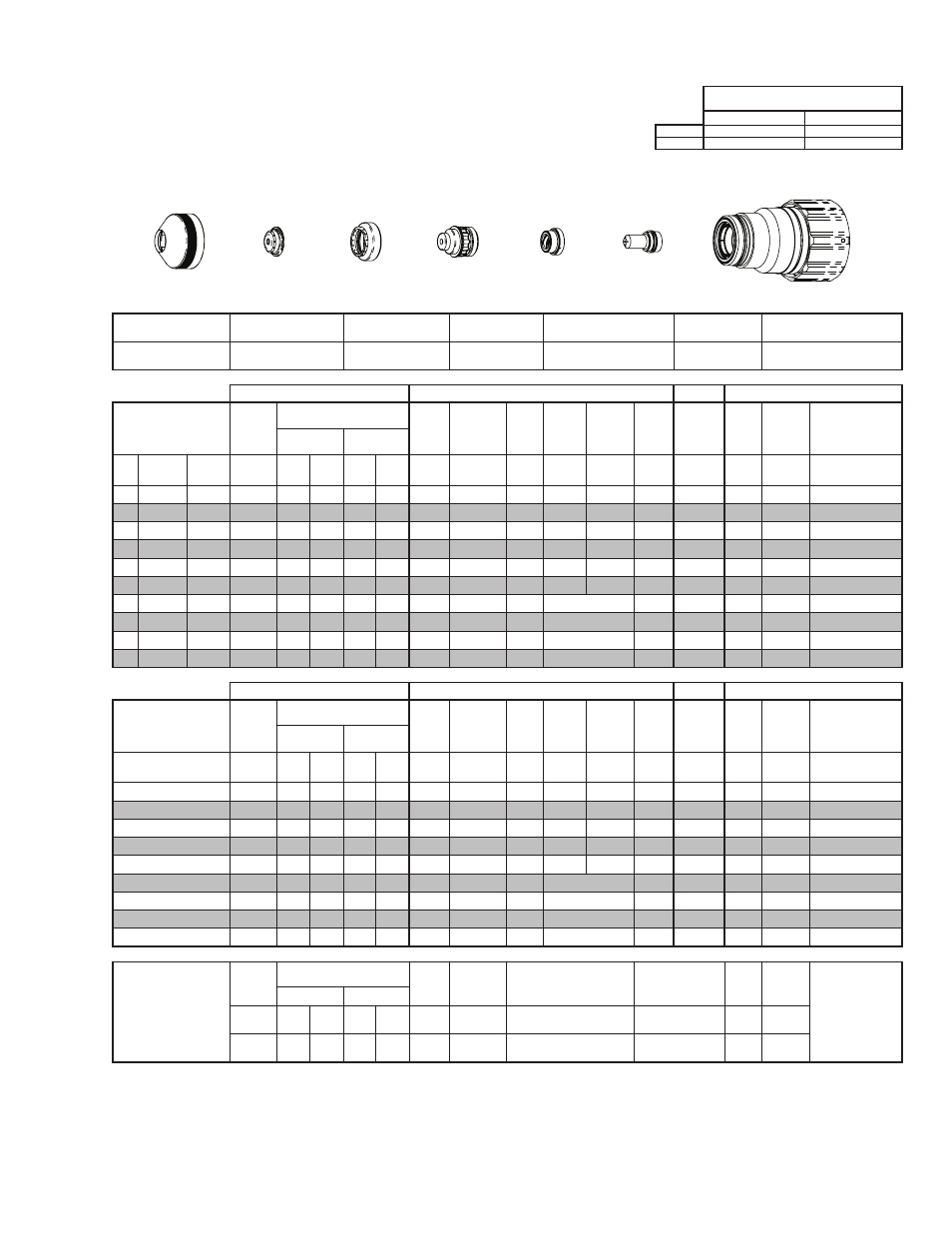

TORCH DATA for Ultra-Cut

Aluminum

Flow Rates (SLPM / SCFH)

200A

H35

N₂

Preflow

- / -

62 / 132

H35 Plasma / N₂ Shield

Cutflow

33 / 71

44 / 94

Shield Retainer

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas Distributor

Electrode

Cartridge

21-1015

< 1” / 25 mm 21-1073

≥ 1” / 25 mm 21-1094

21-1284

21-1095

21-1042

21-1096

21-1022

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (H35) Shield (N₂)

ga

(in)

inch

(psi)

Ball (psi) Ball (psi) (Volts) (in) ±0.005 (sec)

(in)

(in)

(sec)

(in)

(ipm)

(sec)

(in)

-

3/8

0.375

20

100 100 NA 110

165

0.300

0.2

0.300 0.250

0.2

0.400

180

0.2

0.113

-

1/2

0.500

20

100 100 NA 110

168

0.300

0.2

0.250 0.200

0.4

0.350

150

0.2

0.119

-

5/8

0.625

20

100 100 NA 110

170

0.300

0.5

0.250 0.200

0.3

0.350

110

0.3

0.120

-

3/4

0.750

20

100 100 NA 110

172

0.300

0.7

0.300 0.250

0.2

0.400

70

0.4

0.130

-

7/8

0.875

20

100 100 NA 110

178

0.350

1.0

0.350 0.300

0.2

0.450

55

0.5

0.139

-

1

1.000

20

100 100 NA 110

180

0.350

1.3

0.400 0.300

0.2

0.500

40

0.7

0.150

-

1 1/4 1.250

20

100 100 NA 110

185

0.400

0.4

Edge Start

0.2

Edge

32

0.4

0.161

-

1 1/2 1.500

20

100 100 NA 110

195

0.400

0.4

Edge Start

0.2

Edge

25

0.4

0.170

-

1 3/4 1.750

20

100 100 NA 110

198

0.400

0.4

Edge Start

0.2

Edge

20

0.4

0.188

-

2

2.000

20

100 100 NA 110

201

0.400

0.4

Edge Start

0.2

Edge

15

0.4

0.205

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (H35) Shield (N₂)

(mm)

(Bar)

Ball (Bar) Ball (Bar) (Volts) (mm) ±0.1 (sec) (mm)

(mm)

(sec)

(mm)

(mm/

min)

(sec)

(mm)

10

1.4

100 6.9

NA 7.6

165

7.6

0.2

7.4

6.2

0.2

10.0

4460

0.2

2.9

12

1.4

100 6.9

NA 7.6

167

7.6

0.2

6.6

5.4

0.4

9.2

3980

0.2

3.0

15

1.4

100 6.9

NA 7.6

169

7.6

0.4

6.4

5.1

0.3

8.9

3070

0.3

3.0

20

1.4

100 6.9

NA 7.6

174

8.0

0.8

8.0

6.7

0.2

10.5

1660

0.4

3.4

25

1.4

100 6.9 NA 7.6

180

8.9

1.3

10.0

7.6

0.2

12.5

1060

0.7

3.8

30

1.4

100 6.9 NA 7.6

182

10.2

0.4

Edge Start

0.2

Edge

860

0.4

4.0

35

1.4

100 6.9 NA 7.6

190

10.2

0.4

Edge Start

0.2

Edge

720

0.4

4.2

40

1.4

100 6.9 NA 7.6

196

10.2

0.4

Edge Start

0.2

Edge

600

0.4

4.5

50

1.4

100 6.9 NA 7.6

201

10.2

0.4

Edge Start

0.2

Edge

400

0.4

5.2

Marking

Pre Flow

Pressure

(N₂)

Marking Flow Rates /

Pressures

Arc

Voltage

Marking

Height

Pierce Ignition Height

THC and CNC

Delay

Control

Delay

Travel

Speed

Marking quality

degrades as

thickness

decreases.

20A Arc Current

Plasma (N₂)

Shield (N₂)

Burn-through may

happen for thicknesses

< 1/16” (0.063”) /

1.6 mm.

(psi) /

(Bar)

Ball (psi) /

(Bar) Ball

(psi) /

(Bar) (Volts)

(in) ±0.005 /

(mm) ±0.1

(in) ±0.005 / (mm) ±0.1

(sec)

(sec)

(ipm) /

(mm/ min)

15 / 1.0

80

60 /

4.1

NA

80 /

5.5

140 0.120 / 3.0

0.120 / 3.0

0

0.5

300 /

7620

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Cartridge

Electrode

Shield

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Shield Retainer

Art # A-07917_AC

This Art Is For Reference ONLY