Aluminum, Air plasma / air shield, This art is for reference only – Tweco Ultra-Cut Torch Data User Manual

Page 20

TORCH DATA for Ultra-Cut

8-20

Manual 0-4828

Rev BA

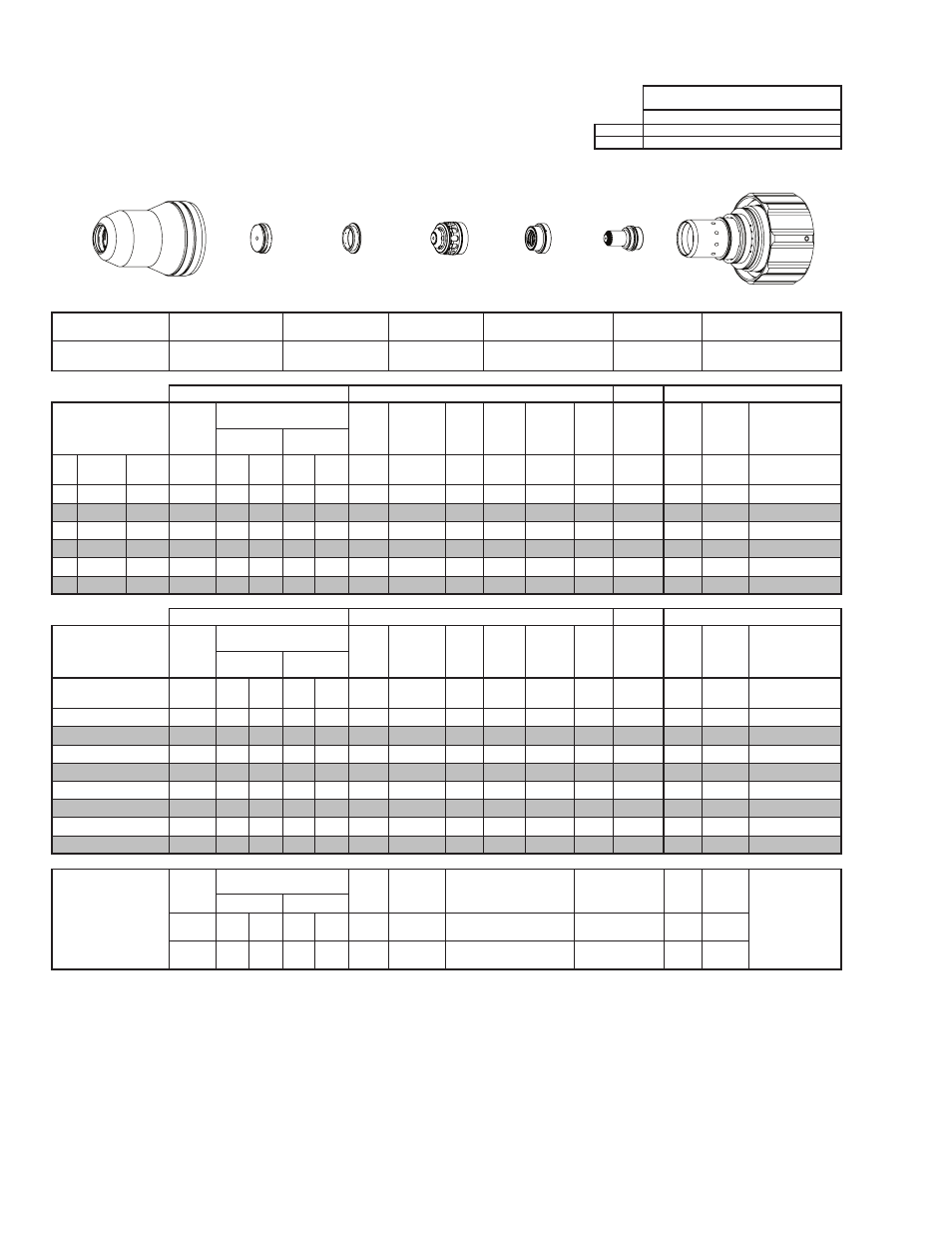

Aluminum

Flow Rates (SLPM / SCFH)

70A

Air

Preflow

66 / 139

Air Plasma / Air Shield

Cutflow

52 / 110

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas Distributor

Electrode

Cartridge

21-1016

21-1035

21-1274

21-1061

21-1041

21-1079

21-1020

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (Air)

Shield (Air)

ga

(in)

inch

(psi)

Ball (psi) Ball (psi) (Volts) (in) ±0.005 (sec)

(in)

(in)

(sec)

(in)

(ipm)

(sec)

(in)

-

-

0.079

84

42

120 70 120

153

0.060

0.0

0.090 0.070

0.4

0.140

300

0.0

0.058

-

-

0.097

84

42

120 70 120

160

0.080

0.1

0.090 0.070

0.3

0.140

200

0.1

0.062

-

-

0.120

84

42

120 70 120

161

0.090

0.1

0.090 0.070

0.3

0.140

175

0.1

0.065

-

3/16

0.188

84

42

120 70 120

162

0.120

0.1

0.090 0.070

0.3

0.140

100

0.1

0.072

-

1/4

0.250

84

42

120 70 120

166

0.140

0.2

0.120 0.110

0.2

0.180

70

0.2

0.073

-

3/8

0.375

84

42

120 70 120

168

0.140

0.3

0.120 0.110

0.2

0.180

60

0.3

0.078

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (Air)

Shield (Air)

(mm)

(Bar)

Ball (Bar) Ball (Bar) (Volts) (mm) ±0.1 (sec)

(mm)

(mm)

(sec)

(mm)

(mm/

min)

(sec)

(mm)

2

5.8

42

8.3

70

8.3

153

1.5

-0.0

2.3

1.8

0.4

3.6

7660

-0.0

1.5

2.5

5.8

42

8.3

70

8.3

160

2.0

0.1

2.3

1.8

0.3

3.6

5040

0.1

1.6

3

5.8

42

8.3

70

8.3

160

2.3

0.1

2.3

1.8

0.3

3.6

4490

0.1

1.6

4

5.8

42

8.3

70

8.3

161

2.7

0.1

2.3

1.8

0.3

3.6

3380

0.1

1.7

5

5.8

42

8.3

70

8.3

163

3.1

0.1

2.4

1.9

0.3

3.7

2430

0.1

1.8

6

5.8

42

8.3

70

8.3

165

3.4

0.2

2.9

2.6

0.2

4.3

1950

0.2

1.8

8

5.8

42

8.3

70

8.3

167

3.6

0.3

3.0

2.8

0.2

4.6

1650

0.3

1.9

10

5.8

42

8.3

70

8.3

168

3.6

0.3

3.0

2.8

0.2

4.6

1490

0.3

2.0

Marking

Pre Flow

Pressure

(N₂)

Marking Flow Rates /

Pressures

Arc

Voltage

Marking

Height

Pierce Ignition Height

THC and CNC

Delay

Control

Delay

Travel

Speed

Marking quality

degrades as

thickness

decreases.

16A Arc Current

Plasma (N₂)

Shield (N₂)

Burn-through may

happen for thicknesses

< 1/16” (0.063”) /

1.6 mm.

(psi) /

(Bar)

Ball (psi) /

(Bar) Ball

(psi) /

(Bar) (Volts)

(in) ±0.005 /

(mm) ±0.1

(in) ±0.005 / (mm) ±0.1

(sec)

(sec)

(ipm) /

(mm/ min)

20 / 1.4

50

40 /

2.8

75

80 /

5.5

135 0.120 / 3.0

0.120 / 3.0

0

0.4

300 /

7620

Electrode

Shield Cap

Tip

Shield Gas

Distributor

Plasma Gas

Distributor

Cartridge

Shield Cup

This Art Is For Reference ONLY

Art # A-07958_AB