Mild steel, 200a bevel cut, O₂ plasma / air shield – Tweco Ultra-Cut Torch Data User Manual

Page 43: This art is for reference only

Manual 0-4828

Rev BA 8-43

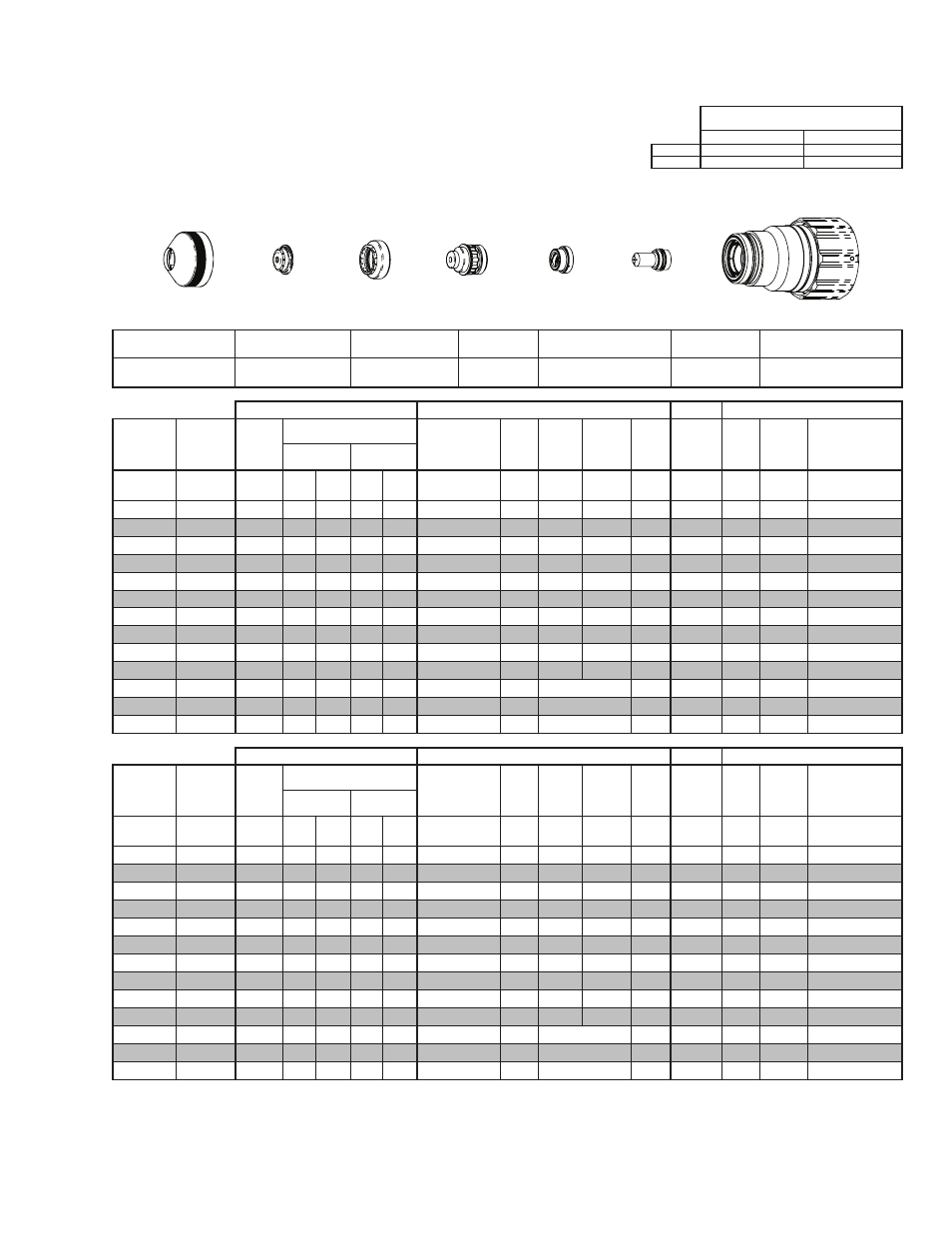

TORCH DATA for Ultra-Cut

Mild Steel

Flow Rates (SLPM / SCFH)

200A Bevel Cut

O₂

Air

Preflow

- / -

162 / 343

O₂ Plasma / Air Shield

Cutflow

102 / 217

133 / 281

Shield Retainer

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas Distributor

Electrode

Cartridge

21-1014

21-1030

21-1285

21-1055

21-1042

21-1093

21-1022

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Effective

Material

Thickness

Min.

Clearance

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Effective Cut

Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (O₂)

Shield (Air)

inch

(in)

(psi)

Ball (psi) Ball (psi)

(in)

(sec)

(in)

(in)

(sec)

(in)

(ipm)

(sec)

(in)

0.188

0.080

15

100 100 NA 100 0.130 - 0.550 0.2

0.200 0.150

0.5

0.300

250

0.2

0.142

0.250

0.080

15

100 100 NA 100 0.130 - 0.550 0.2

0.200 0.150

0.5

0.300

200

0.2

0.148

0.375

0.080

15

100 100 NA 100 0.150 - 0.550 0.3

0.250 0.200

0.5

0.350

140

0.3

0.162

0.500

0.080

15

100 100 NA 100 0.170 - 0.550 0.7

0.250 0.200

0.5

0.350

115

0.5

0.167

0.625

0.080

15

100 100 NA 100 0.200 - 0.550 0.9

0.250 0.200

0.5

0.350

80

0.6

0.186

0.750

0.080

15

100 100 NA 100 0.200 - 0.550 1.3

0.300 0.250

0.5

0.400

65

0.8

0.186

0.875

0.080

15

100 100 NA 100 0.200 - 0.550 1.6

0.300 0.250

0.5

0.400

57

1.0

0.185

1.000

0.080

15

100 100 NA 100 0.200 - 0.550 1.9

0.300 0.250

0.5

0.400

48

1.2

0.193

1.250

0.080

15

100 100 NA 100 0.200 - 0.550 3.2

0.325 0.250

0.5

0.425

30

2.0

0.196

1.500

0.080

15

100 100 NA 100 0.200 - 0.550 5.8

0.350 0.300

0.5

0.450

20

4.0

0.201

1.750

0.080

15

100 100 NA 100 0.200 - 0.550 1.0

Edge Start

0.5

Edge

15

1.0

0.203

2.000

0.080

15

100 100 NA 100 0.200 - 0.550 1.0

Edge Start

0.5

Edge

10

1.0

0.204

2.500

0.080

15

100 100 NA 100 0.200 - 0.550 1.0

Edge Start

0.5

Edge

8

1.0

0.210

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Effective

Material

Thickness

Min.

Clearance

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Effective Cut

Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (O₂)

Shield (Air)

(mm)

(mm)

(Bar)

Ball (Bar) Ball (Bar)

(mm)

(sec)

(mm)

(mm)

(sec)

(mm)

(mm/

min)

(sec)

(mm)

5

2.0

1.0

100 6.9

NA

6.9

3.3 - 14.0

0.2

5.1

3.8

0.5

7.6

6170

0.2

3.6

6

2.0

1.0

100 6.9

NA

6.9

3.3 - 14.0

0.2

5.1

3.8

0.5

7.6

5360

0.2

3.7

8

2.0

1.0

100 6.9

NA

6.9

3.6 - 14.0

0.3

5.7

4.5

0.5

8.3

4290

0.3

3.9

10

2.0

1.0

100 6.9

NA

6.9

3.9 - 14.0

0.4

6.4

5.1

0.5

8.9

3460

0.3

4.1

12

2.0

1.0

100 6.9

NA

6.9

4.2 - 14.0

0.6

6.4

5.1

0.5

8.9

3060

0.5

4.2

15

2.0

1.0

100 6.9

NA

6.9

4.9 - 14.0

0.8

6.4

5.1

0.5

8.9

2280

0.6

4.6

20

2.0

1.0

100 6.9

NA

6.9

5.1 - 14.0

1.4

7.6

6.4

0.5

10.2

1590

0.9

4.7

25

2.0

1.0

100 6.9

NA

6.9

5.1 - 14.0

1.9

7.6

6.4

0.5

10.2

1250

1.2

4.9

30

2.0

1.0

100 6.9

NA 6.9

5.1 - 14.0

2.8

8.1

6.4

0.5

10.6

890

1.8

5.0

35

2.0

1.0

100 6.9

NA 6.9

5.1 - 14.0

4.5

8.6

7.0

0.5

11.1

630

3.0

5.0

40

2.0

1.0

100 6.9

NA

6.9

5.1 - 14.0

1.0

Edge Start

0.5

Edge

470

1.0

5.1

50

2.0

1.0

100 6.9

NA

6.9

5.1 - 14.0

1.0

Edge Start

0.5

Edge

270

1.0

5.2

60

2.0

1.0

100 6.9

NA

6.9

5.1 - 14.0

1.0

Edge Start

0.5

Edge

220

1.0

5.3

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Cartridge

Electrode

Shield

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Shield Retainer

Art # A-07917_AC

This Art Is For Reference ONLY

8.04 Robotic and Bevel Cutting 150 - 200 Amp