Stainless steel, N₂ plasma / h₂o shield, This art is for reference only – Tweco Ultra-Cut Torch Data User Manual

Page 19

Manual 0-4828

Rev BA 8-19

TORCH DATA for Ultra-Cut

Stainless Steel

Flow Rates

70A

N₂ (SLPM / SCFH)

H₂O (GPH / LPH)

Preflow

15 / 31

5 / 19

N₂ Plasma / H₂O Shield

Cutflow

8 / 17

5 / 19

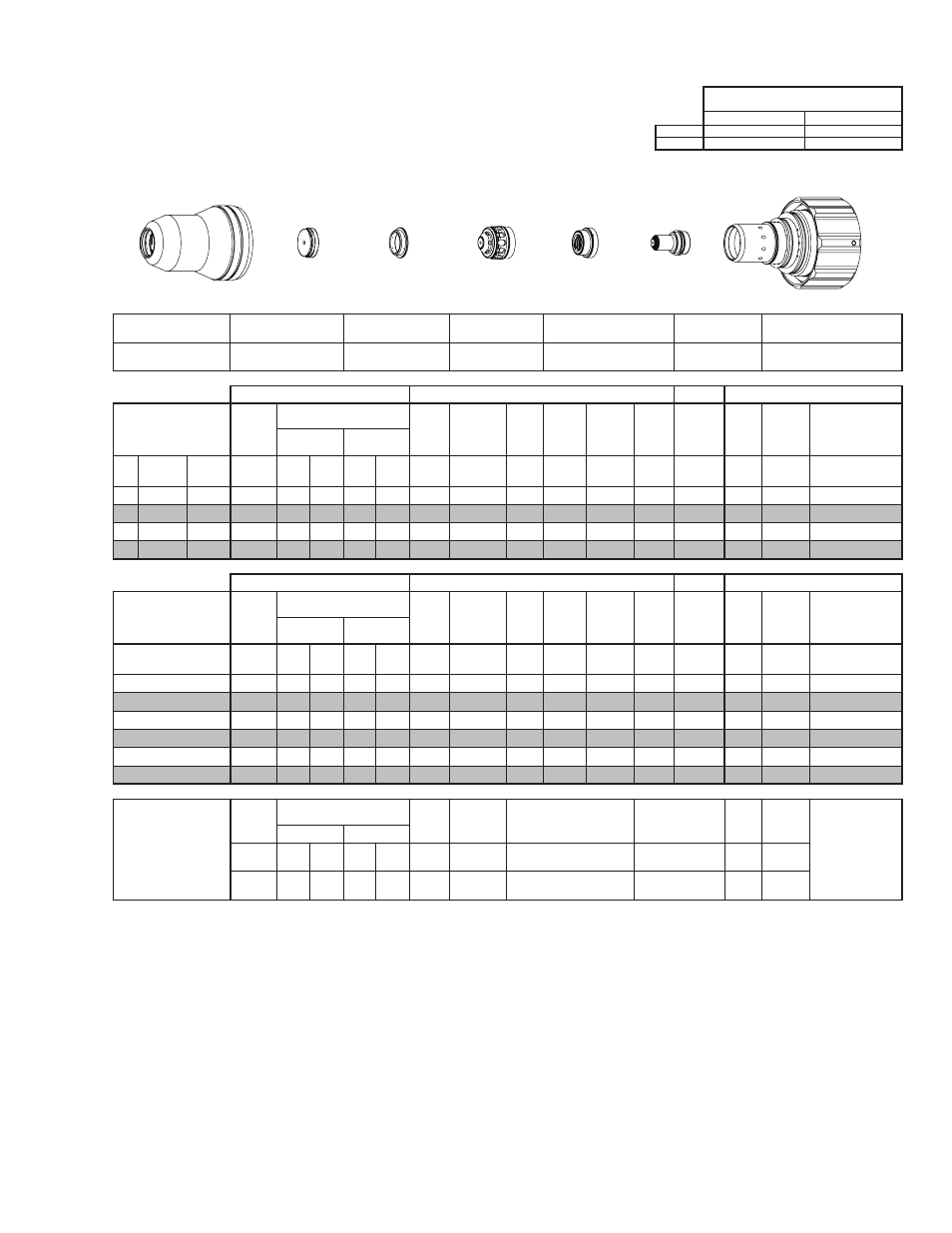

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas Distributor

Electrode

Cartridge

21-1016

21-1047

21-1274

21-1064

21-1041

21-1084

21-1020

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (N₂) Shield (H₂O)

ga

(in)

inch

(psi)

Ball (psi) Ball (psi)* (Volts) (in) ±0.005 (sec)

(in)

(in)

(sec)

(in)

(ipm)

(sec)

(in)

10

-

0.141

45

55

90

5

55

146

0.100

0.3

0.150 0.150

0.2

0.250

120

0.3

0.075

-

3/16

0.188

45

55

90

5

55

150

0.100

0.4

0.150 0.150

0.2

0.250

90

0.4

0.086

-

1/4

0.250

45

55

90

5

55

159

0.150

0.5

0.150 0.150

0.2

0.250

50

0.5

0.095

-

3/8

0.375

45

55

90

5

55

168

0.150

0.7

0.150 0.150

0.2

0.250

35

0.7

0.103

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (N₂) Shield (H₂O)

(mm)

(Bar)

Ball (Bar) Ball (Bar)* (Volts) (mm) ±0.1 (sec) (mm)

(mm)

(sec)

(mm)

(mm/

min)

(sec)

(mm)

3

3.1

55

6.2

5

3.8

144

2.5

0.3

3.8

3.8

0.2

6.4

3420

0.3

1.8

4

3.1

55

6.2

5

3.8

147

2.5

0.3

3.8

3.8

0.2

6.4

2780

0.3

2.0

5

3.1

55

6.2

5

3.8

151

2.7

0.4

3.8

3.8

0.2

6.4

2130

0.4

2.2

6

3.1

55

6.2

5

3.8

157

3.5

0.5

3.8

3.8

0.2

6.4

1490

0.5

2.4

8

3.1

55

6.2

5

3.8

164

3.8

0.6

3.8

3.8

0.2

6.4

1070

0.6

2.5

10

3.1

55

6.2

5

3.8

169

3.8

0.7

3.8

3.8

0.2

6.4

830

0.7

2.6

Marking

Pre Flow

Pressure

(N₂)

Marking Flow Rates /

Pressures

Arc

Voltage

Marking

Height

Pierce Ignition Height

THC and CNC

Delay

Control

Delay

Travel

Speed

Marking quality

degrades as

thickness

decreases.

18A Arc Current

Plasma (N₂)

Shield (N₂)

Burn-through may

happen for thicknesses

< 1/16” (0.063”) /

1.6 mm.

(psi) /

(Bar)

Ball (psi) /

(Bar) Ball

(psi) /

(Bar) (Volts)

(in) ±0.005 /

(mm) ±0.1

(in) ±0.005 / (mm) ±0.1

(sec)

(sec)

(ipm) /

(mm/ min)

20 / 1.4

50

40 /

2.8

75

80 /

5.5

150 0.120 / 3.0

0.120 / 3.0

0

0.4

300 /

7620

* Pressure of the water supply line should be regulated by customer pressure regulator.

Note 1: Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the ohmic sensing circuit.

Note 2: Water source used for shield must be demineralized.

Electrode

Shield Cap

Tip

Shield Gas

Distributor

Plasma Gas

Distributor

Cartridge

Shield Cup

This Art Is For Reference ONLY

Art # A-07958_AB