Aluminum, 300a, H35 plasma / n₂ shield – Tweco Ultra-Cut Torch Data User Manual

Page 55

Manual 0-4828

Rev BA 8-55

TORCH DATA for Ultra-Cut

Aluminum

Flow Rates (SLPM / SCFH)

300A

H35

N₂

Preflow

- / -

74 / 156

H35 Plasma / N₂ Shield

Cutflow

44 / 93

51 / 107

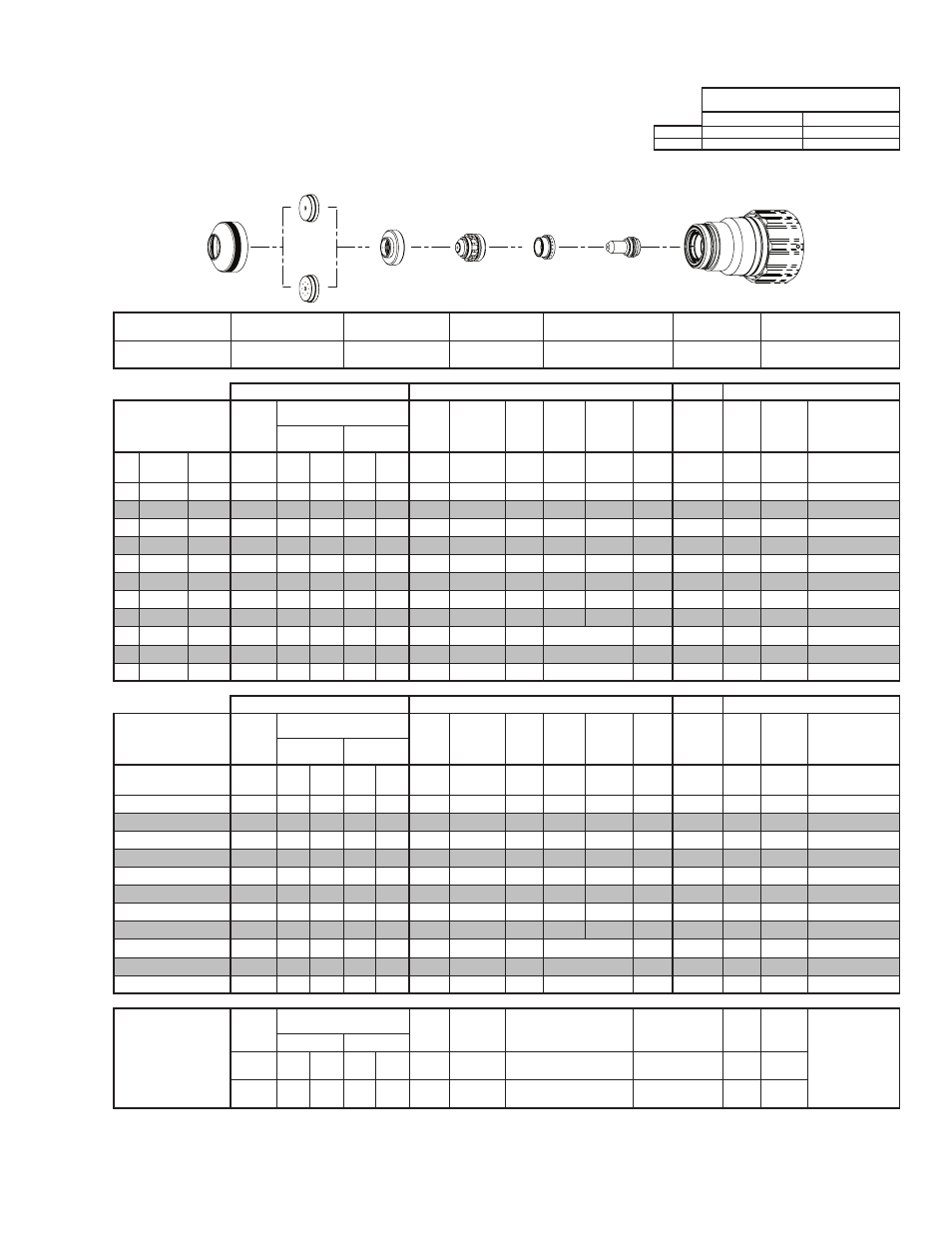

Shield Retainer

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas Distributor

Electrode

Cartridge

21-1015

< 1” / 25 mm 21-1038

≥ 1” / 25 mm 21-1039

21-1284

21-1065

21-1041

21-1091

21-1022

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (H35) Shield (N₂)

ga

(in)

inch

(psi)

Ball (psi) Ball (psi) (Volts) (in) ±0.005 (sec)

(in)

(in)

(sec)

(in)

(ipm)

(sec)

(in)

-

1/4

0.250

20

120 100 NA 120

163

0.400

0.1

0.300 0.250

0.5

0.400

300

0.1

0.182

-

3/8

0.375

20

120 100 NA 120

163

0.400

0.2

0.300 0.250

0.4

0.400

275

0.2

0.186

-

1/2

0.500

20

120 100 NA 120

153

0.300

0.4

0.300 0.250

0.3

0.400

210

0.3

0.174

-

5/8

0.625

20

120 100 NA

90

160

0.300

0.6

0.250 0.300

0.2

0.350

140

0.4

0.169

-

3/4

0.750

20

120 100 NA

90

159

0.300

0.8

0.250 0.300

0.2

0.350

110

0.5

0.172

-

7/8

0.875

20

120 100 NA

90

162

0.300

1.0

0.300 0.250

0.2

0.400

95

0.6

0.183

-

1

1.000

20

120 100 NA 120

165

0.350

1.2

0.350 0.300

0.2

0.450

85

0.7

0.190

-

1 1/4 1.250

20

120 100 NA 120

168

0.400

1.6

0.400 0.400

0.2

0.500

60

0.8

0.205

-

1 1/2 1.500

20

120 100 NA 120

177

0.400

1.5

Edge Start

0.2

Edge

45

1.0

0.215

-

1 3/4 1.750

20

120 100 NA 120

182

0.400

0.4

Edge Start

0.2

Edge

35

0.4

0.226

-

2

2.000

20

120 100 NA 120

188

0.400

0.4

Edge Start

0.2

Edge

25

0.4

0.215

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(N₂)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (H35) Shield (N₂)

(mm)

(Bar)

Ball (Bar) Ball (Bar) (Volts) (mm) ±0.1 (sec)

(mm)

(mm)

(sec)

(mm)

(mm/

min)

(sec)

(mm)

6

1.4

120 6.9

NA

8.3

163

10.2

0.1

7.6

6.4

0.5

10.2

7690

0.1

4.6

8

1.4

120 6.9

NA

8.3

163

10.2

0.2

7.6

6.4

0.4

10.2

7290

0.2

4.7

10

1.4

120 6.9

NA

8.3

162

9.8

0.2

7.6

6.4

0.4

10.2

6740

0.2

4.7

12

1.4

120 6.9

NA

8.3

155

8.2

0.4

7.6

6.4

0.3

10.2

5700

0.3

4.5

15

1.4

120 6.9

NA

6.8

158

7.6

0.5

6.7

7.3

0.2

9.2

4050

0.4

4.3

20

1.4

120 6.9

NA

6.2

160

7.6

0.9

6.7

7.2

0.2

9.3

2680

0.5

4.5

25

1.4

120 6.9

NA

8.0

165

8.7

1.2

8.7

7.5

0.2

11.3

2190

0.7

4.8

30

1.4

120 6.9 NA 8.3

167

9.8

1.5

9.8

9.5

0.2

12.4

1700

0.8

5.1

35

1.4

120 6.9 NA 8.3

175

10.2

1.5

Edge Start

0.2

Edge

1270

1.0

5.3

40

1.4

120 6.9 NA 8.3

178

10.2

1.2

Edge Start

0.2

Edge

1070

0.8

5.5

50

1.4

120 6.9 NA 8.3

187

10.2

0.4

Edge Start

0.2

Edge

670

0.4

5.5

Marking

Pre Flow

Pressure

(N₂)

Marking Flow Rates /

Pressures

Arc

Voltage

Marking

Height

Pierce Ignition Height

THC and CNC

Delay

Control

Delay

Travel

Speed

Marking quality

degrades as

thickness

decreases.

24A Arc Current

Plasma (N₂)

Shield (N₂)

Burn-through may

happen for thicknesses

< 1/16” (0.063”) /

1.6 mm.

(psi) /

(Bar)

Ball (psi) /

(Bar)

Ball (psi) /

(Bar) (Volts)

(in) ±0.005 /

(mm) ±0.1

(in) ±0.005 / (mm) ±0.1

(sec)

(sec)

(ipm) /

(mm/ min)

15 / 1.0

80

60 /

4.1

NA

90 /

6.2

135 0.120 / 3.0

0.120 / 3.0

0

0.4

300 /

7620

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Electrode

Shield Retainer

Tip

Art # A-08567_AB

Plasma Gas

Distributor

Cartridge Assembly

This Art Is For Reference ONLY

Shield Cap

Shield Gas

Distributor