Mild steel, 300a xtl, O₂ plasma / air shield – Tweco Ultra-Cut Torch Data User Manual

Page 52

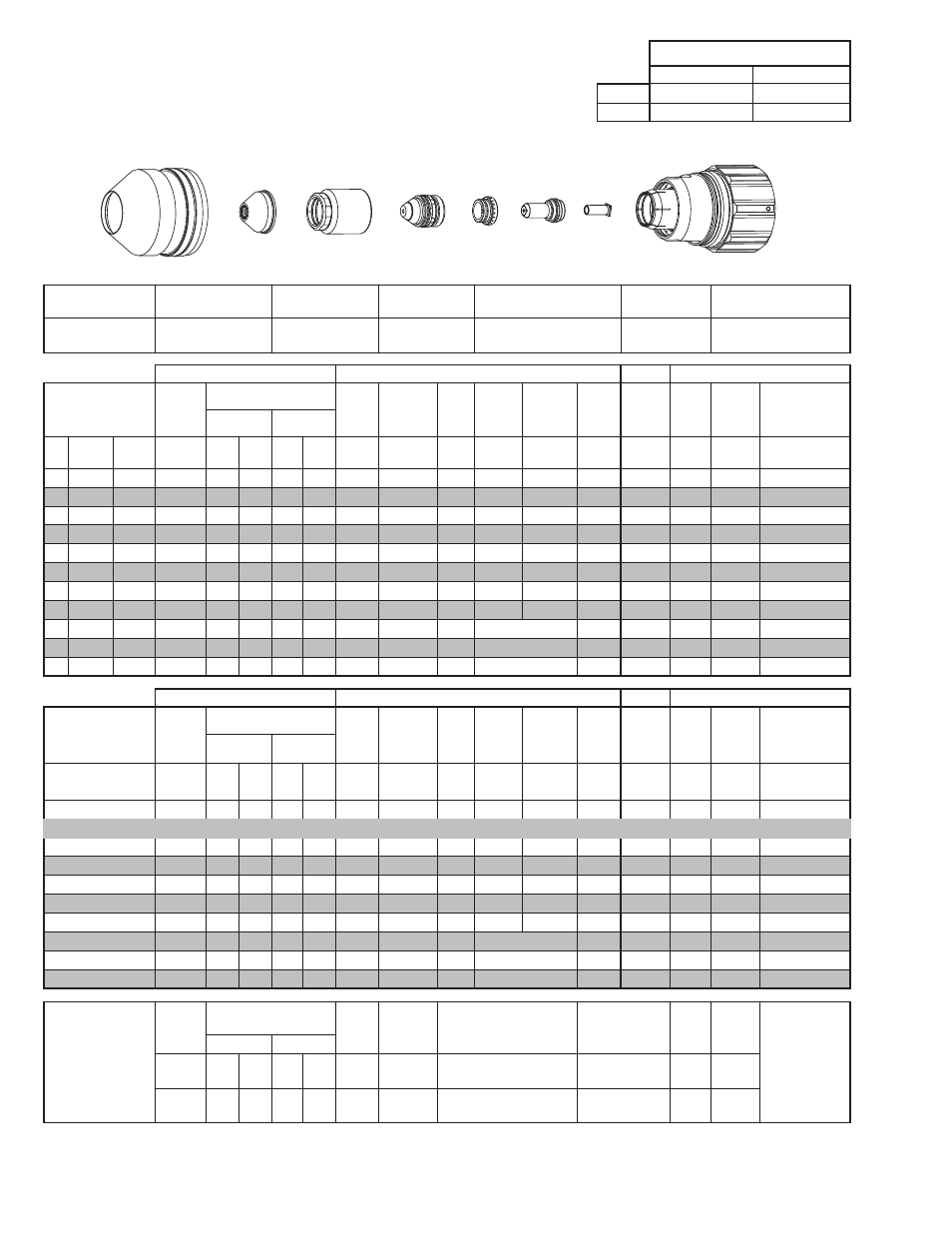

TORCH DATA for Ultra-Cut

8-52

Manual 0-4828

Rev BA

Mild Steel

Flow Rates (SLPM / SCFH)

300A XTL

O₂

Air

Preflow

- / -

194 / 412

O₂ Plasma / Air Shield

Cutflow

27 / 58

160 / 340

Shield Cup

Shield Cap

Shield Gas Distributor

Tip

Plasma Gas Distributor

Electrode /

Tube

Cartridge

21-1305

21-1105

21-1295

21-1160

21-1042

21-1308

9-7921

21-1300

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (O₂)

Shield (Air)

ga

(in)

inch

(psi)

Ball (psi) Ball (psi) (Volts) (in) ±0.005 (sec)

(in)

(in)

(sec)

(in)

(ipm)

(sec)

(in)

-

1/2 0.500

20

100 100 NA 100

159

0.200

0.3

0.400

0.200

0.5

0.450

140

0.2

0.149

-

5/8 0.625

20

100 100 NA 100

161

0.200

0.4

0.400

0.200

0.5

0.450

115

0.3

0.179

-

3/4 0.750

20

100 100 NA 100

158

0.200

0.6

0.400

0.200

0.5

0.450

100

0.4

0.185

-

7/8 0.875

20

100 100 NA 100

161

0.200

0.8

0.400

0.200

0.5

0.450

85

0.6

0.182

-

1

1.000

20

100 100 NA 100

164

0.200

1.1

0.400

0.250

0.5

0.450

70

0.9

0.183

-

1 1/4 1.250

20

100 100 NA 100

164

0.200

1.5

0.400

0.300

0.5

0.500

50

1.2

0.193

-

1 1/2 1.500

20

100 100 NA 100

175

0.200

2.9

0.400

0.350

0.5

0.500

35

2.7

0.208

-

1 3/4 1.750

20

100 100 NA 100

179

0.200

5.3

0.400

0.400

0.5

Edge

25

5.2

0.250

-

2

2.000

20

100 100 NA 100

182

0.200

1.0

Edge Start

0.5

Edge

18

1.0

0.245

-

2 1/2 2.500

20

100 100 NA 100

201

0.200

1.0

Edge Start

0.5

Edge

10

1.0

0.416

-

3

3.000

20

100 100 NA 100

215

0.200

1.0

Edge Start

0.5

Edge

7

1.0

0.500

GCM-2010

SC-3000 Torch Height Control (THC)

Basic THC

CNC Control

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Arc

Voltage Cut Height

THC

Pierce

Delay

Pierce

Ignition

Height

Elevation

Height

Control

Delay

Pierce

Height

without

Elevation

Travel

Speed

CNC

Motion

Delay

Max Kerf Width

@ Rec. Speed

Plasma (O₂)

Shield (Air)

(mm)

(Bar)

Ball (Bar) Ball (Bar) (Volts) (mm) ±0.1 (sec)

(mm)

(mm)

(sec)

(mm)

(mm/

min)

(sec)

(mm)

12

1.4

100 6.9 NA 6.9

159

5.1

0.3

10.2

5.1

0.5

11.4

3700

0.2

3.6

15

1.4

100 6.9 NA 6.9

160

5.1

0.4

10.2

5.1

0.5

11.4

3100

0.3

4.3

20

1.4

100 6.9 NA 6.9

159

5.1

0.7

10.2

5.1

0.5

11.4

2430

0.5

4.7

25

1.4

100 6.9 NA 6.9

164

5.1

1.1

10.2

6.2

0.5

11.4

1830

0.9

4.6

30

1.4

100 6.9 NA 6.9

164

5.1

1.4

10.2

7.3

0.5

12.4

1410

1.1

4.8

35

1.4

100 6.9 NA 6.9

170

5.1

2.2

10.2

8.3

0.5

12.7

1080

2.0

5.1

40

1.4

100 6.9 NA 6.9

176

5.1

3.6

10.2

9.3

0.5

Edge

810

3.4

5.6

50

1.4

100 6.9 NA 6.9

181

5.1

1.0

Edge Start

0.5

Edge

470

1.0

5.9

60

1.4

100 6.9 NA 6.9

196

5.1

1.0

Edge Start

0.5

Edge

310

1.0

9.4

70

1.4

100 6.9 NA 6.9

208

5.1

1.0

Edge Start

0.5

Edge

220

1.0

11.7

Marking

Pre Flow

Pressure

(N₂)

Marking Flow Rates /

Pressures

Arc

Voltage

Marking

Height

Pierce Ignition Height

THC and CNC

Delay

Control

Delay

Travel

Speed

Marking quality

degrades as

thickness

decreases.

30A Arc Current

Plasma (N₂)

Shield (N₂)

(psi) /

(Bar)

Ball (psi) /

(Bar) Ball

(psi) /

(Bar) (Volts)

(in) ±0.005 /

(mm) ±0.1

(in) ±0.005 / (mm) ±0.1

(sec)

(sec)

(ipm) /

(mm/ min)

15 / 1.0

80

60 /

4.1

NA

90 /

6.2

158

0.120 / 3.0

0.120 / 3.0

0

0.5

300 /

7620

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Use CCM 4.5.0 or later and Electronic Cut Chart 2.4.0 or later

This Art Is For Reference Only

Art# A-10270_AB

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Gas

Distributor Electrode

Tube

Cartridge Assembly