2 gas flow, Gas flow diagram, Display – Metrohm 774 Oven Sample Processor User Manual

Page 45

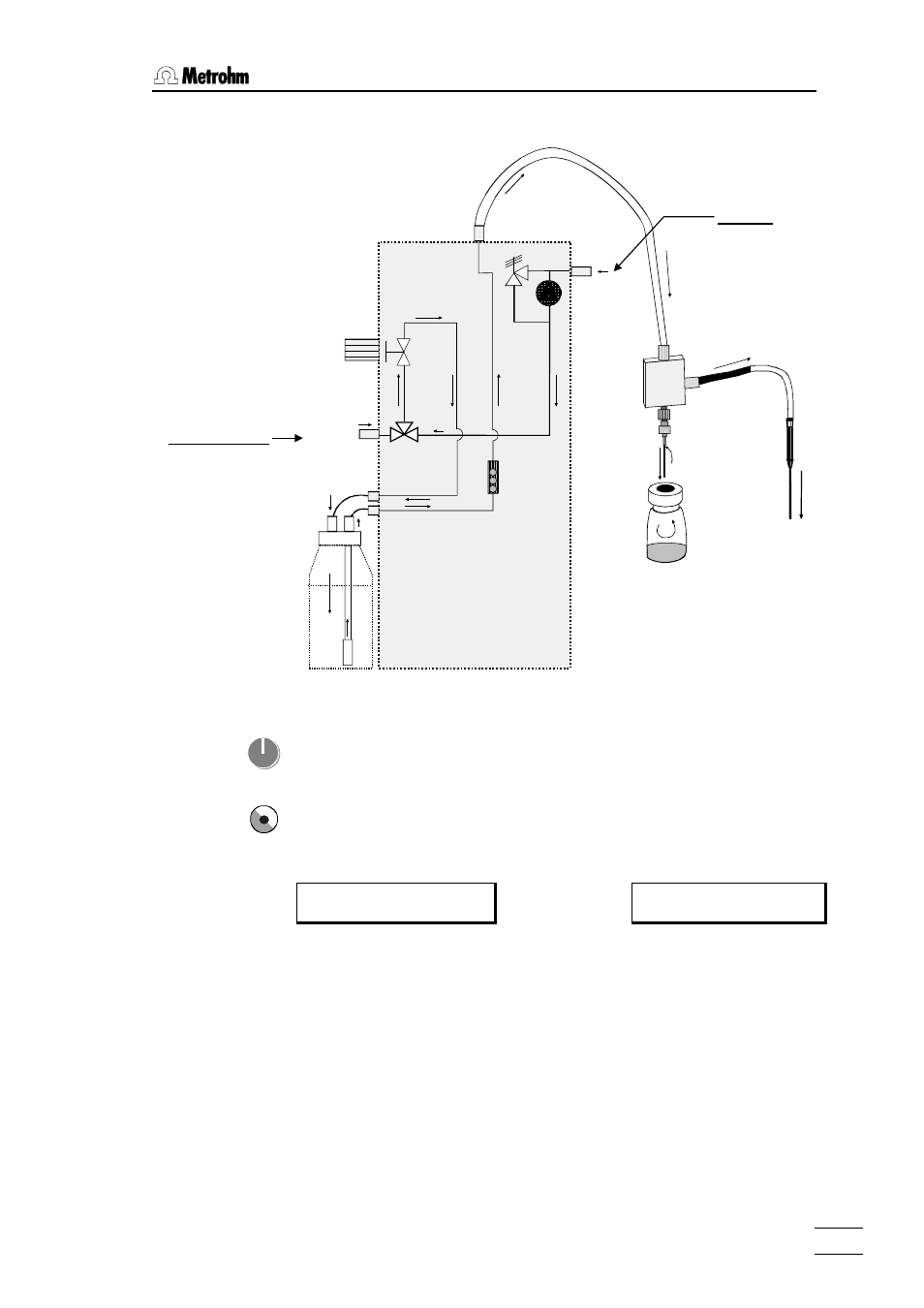

4.2 Gas flow

774 Oven Sample Processor, Instructions for use

39

Gas flow diagram:

inlet filter

flow meter

pump

pressure control

valve

gas flow

control knob

solenoid

valve

Air/N2 in

from Drying flask

to Drying flask

tower

outlet needle

injection

needle

sample

titration cell

conveying tubing

left-hand

instrument

side

Gas flow

Air/N

2

in

The gas flow can be set manually with the help of the gas flow regulator and

the flowmeter. The flow rate of the carrier gas is shown on the display in

mL/min or L/h so that it is easy to set the required gas flow with the rotary

knob of the gas flow regulator. A gas flow of 20 to 100 mL/min is required;

this depends on the determination method and moisture in the sample.

Display:

******** counter 1/36

110°C 55 mL/min ready

or:

(

press

gas flow 55 mL/min

heater temp. 120°C

The gas flow is monitored automatically. A lower and an upper limit can be

defined for the gas flow; if these are undercut or exceeded an error mes-

sage is displayed. It is recommended that the safety limits (min. flow and

max. flow) are not set too closely for gas flow monitoring. A range of ap-

prox. 30 mL/min should be set.

During needle penetration and removal the gas flow should be switched off

as large variations in gas pressure occur during these processes. This

avoids unnecessary error messages.

air inlet

inert gas inlet