1398-pdm-25, 50, 100, and 150, 3'0 dqg, R s t – Rockwell Automation 1398-PDM-xxx ULTRA Plus Series Positioning Drive Module User Manual

Page 69

Publication 1398-5.1 — January 2000

Wire the ULTRA Plus PDM Components 3-5

Auxiliary Logic Power

6LQJOH SKDVH $& SRZHU 9$& PD\ EH VXSSOLHG WR WKH LQWHUQDO ORJLF

VXSSO\ WKURXJK / $8; DQG /1 $8;

$X[LOLDU\ VXSSO\ SRZHU WR WKH LQWHUQDO ORJLF VXSSO\ LV XVHIXO LI WKH 8/75$ 3OXV

3'0 ORJLF PXVW VWD\ 21 ZKHQ WKH PRWRU SRZHU PXVW EH WXUQHG 2))

$EVROXWH SRVLWLRQLQJ LV RQH H[DPSOH RI ZKHQ WKLV ZRXOG EH XVHIXO VLQFH

SRVLWLRQ LQIRUPDWLRQ LV PDLQWDLQHG DV ORQJ DV ORJLF SRZHU LV RQ $QRWKHU

H[DPSOH ZRXOG EH PDLQWDLQLQJ WKH 8/75$ 3OXV 3'0 ORJLF SRZHU VR WKH

8/75$ 3OXV 3'0 VHULDO LQWHUIDFH FRXOG EH XVHG IRU GLDJQRVWLFV

1398-PDM-25, 50, 100, and 150

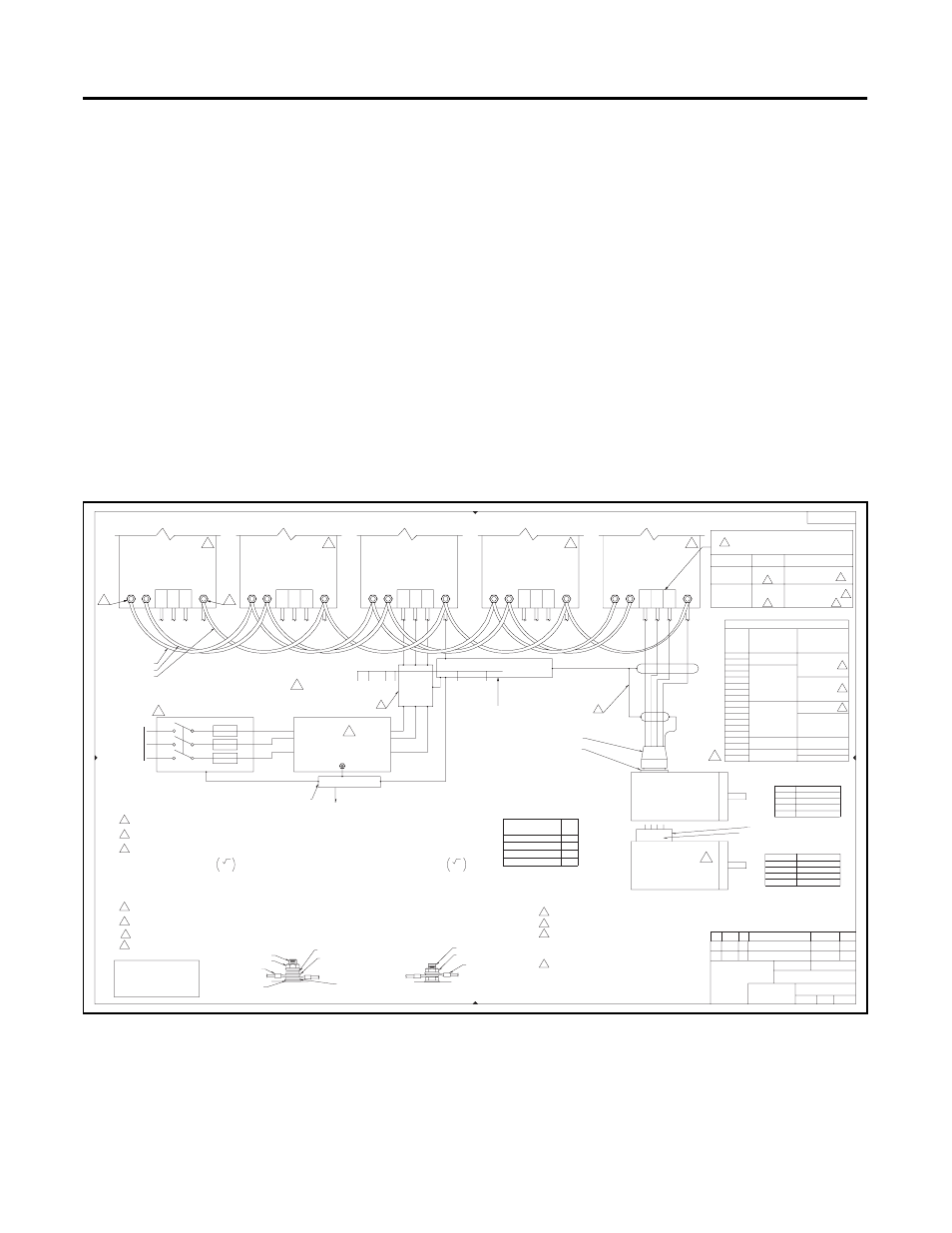

Figure 3.4

Power Wiring Diagram (1398-PDM-25, 50, 100, and 100)

11

10

10

10

5

4

4

9

8

9

8

6

4

4

5

7

7

1

2

3

1

1

A

B

C

D

PIN

SIGNAL

R

S

T

MOTOR CASE

0020-5091-001

0020-5091-002

0020-5091-003

0020-5091-004

RELIANCE

KVA

3

6

12

18

U

V

W

E

TERMINAL

SIGNAL

S

R

T

MOTOR CASE

1

1

5

7

6

6

4

1

A00787

TM

5-30-95

RB

A1

CHG'D NOTE 1

2

3

11

21871

JM

__

__

B

ADDED H-SERIES MTR OPTION

WIRE SIZES ARE RECOMMENDATIONS. THE REQUIREMENTS

OF LOCAL REGULATIONS MUST BE OBSERVED.

AC LINE FILTER AND SHIELDED MOTOR CABLE ARE OPTIONAL.

TO BE USED FOR IMPROVING THE SYSTEM'S ELECTROMAGNETIC

COMPATABILITY. WIRING BETWEEN THE POWER SUPPLY AND

FILTER SHOULD BE AS SHORT AS POSSIBLE. THE COMMON

GROUND SHOULD BE AS CLOSE TO THE MODULE AS POSSIBLE.

COMMON GROUNDING POINT FOR

POWER SUPPLY-DRIVE MODULE

SYSTEM

TO PROTECTIVE

EARTH TERMINAL

MACHINE COMMON

GROUNDING BUS BAR

AC

LINE

FILTER

9101-0411

POWER WIRING CONNECTIONS

.XXX±.010

DECIMALS.XX±.020

FRACTIONS:±1/64"

DO NOT SCALE DRAWING

ANGLES ±1ANGLES ˚

TOLERANCE ON:

FILLETS AND ROUNDS .02 R MAX

BREAK ALL EDGES .02 MAX

DIMENSIONS ARE IN INCHES

DATE

DATE

D

PART NO.

DWG SIZE

SHEET

SCALE

N/A

of

REV ECOCHKR

DATE

REVISION DESCRIPTION

BY

DESIGN ENGR

DRAWN BY

5-30-95

2-2-95

TM

BCB

PART NO.

UNLESS OTHERWISE SPECIFIED

9101-0411

1-24-95

1

1

CO

TM

1398-PDM-25, 50,

100, and 150

21244

A

RELEASED

TORQUE TO 11.5 LB-IN.

TORQUE TO 24 LB-IN.

POWER WIRES MUST

BE CORRECTLY

PHASED

R,S AND T MOTOR

(GAUGE/mmÉ)

60˚C COPPER ONLY

TERMINALS

PRODUCT

PSM-125

PSM-50

AND ALL

DRIVE MODULES

L1,L2,L3

L1,L2,L3

R,S,T

POWER SUPPLY MODULE AND

DRIVE MODULE TERMINALS

6-0 AWG/16-55mmÉ

8 AWG/10mmÉ

10-4 AWG/6-25mmÉ

14-12 AWG/2.5-4mmÉ

16 AWG/1.5mmÉ

ACCEPTABLE WIRE RANGE

MOTOR POWER WIRES R,S,T,GND

MINIMUM

RECOMMENDED

POWER WIRE

(GAUGE/mmÉ)

MOTOR

16 AWG/1.2mmÉ

12 AWG/3.0mmÉ

8 AWG/8.6mmÉ

4 AWG/21.6mmÉ

TERMINAL BLOCK

S-3007

S-3016

S-4030

F-4030

S-4050

F-4050

S-4075

F-4075

S-6100

F-6100

S-6200

F-6200

S-6300

F-6300

S-8350

S-8500

I-5300

I-6600

MOTOR POWER

MATING CONNECTOR

16 AWG/1.5mmÉ

14 AWG/2.5mmÉ

12 AWG/4mmÉ

8 AWG/10mmÉ

6 AWG/16mmÉ

8 AWG/10mmÉ

6 AWG/16mmÉ

CONTACT SIZE

(GAUGE/mmÉ)

208/230/240/380/460/480 VAC PRIMARY, 115/230

VAC SECONDARY, 50/60 Hz

PART NUMBER

H-SERIES, S-SERIES,

F-SERIES AND W-SERIES

MOTORS

I-5300 AND I-6600

MOTORS

100 TO 240 VAC RMS

3 PHASE INPUT POWER

PHASING OF L1,L2 AND L3

INPUT POWER IS ARBITRARY

RED WIRE

BLACK WIRE

GREEN WIRE

DC BUS POS, NEG, AND GND WIRES (1 EACH)

ARE PROVIDED WITH EACH DRIVE MODULE

L1

L2

L3

FUSED DISCONNECT

FUSED DISCONNECT

3 PHASE AC LINE

50/60 Hz

TRANSFORMER

CHASSIS

3 PHASE ISOLATION OR AUTO

TRANSFORMER.

(OPTIONAL, NOT REQUIRED

WHEN DESIRED INPUT VOLTAGE

IS AVAILABLE DIRECTLY

FROM THE LINE).

POS

NEG

GND

DRIVE MODULE

POS

NEG

GND

DRIVE MODULE

POS

NEG

GND

MOTOR TERMINAL BOX

MOTOR POWER TERMINAL STRIP

MOTOR POWER TERMINAL STRIP

MOTOR POWER CONNECTOR

MOTOR POWER CONNECTOR

MOTOR POWER MATING CONNECTOR

POWER SUPPLY MODULE

POS

NEG

GND

DRIVE MODULE

POS

NEG

GND

DRIVE MODULE

M6 TERMINAL POST

M6 NUT

CONNECTING LUGS

M6 TERMINAL POST

M6 NUT

SPRING DISK WASHERS

FLAT WASHER

CONNECTING LUGS

DRIVE OR POWER SUPPLY

BUS BAR

TERMINAL POST BASE

c) SEE DRAWING 9101-0132, TRANSFORMER LOAD REGULATION, TO DETERMINE EFFECT OF PEAK LOADS ON SYSTEM DC BUS VOLTAGE.

FOR WIRE GAUGES NOTED: STRIPPED ENDS OF STRANDED WIRES MUST BE FULLY TINNED SO WIRE DIA. STAYS LARGE ENOUGH FOR

PROPER CLAMPING IN POWER SUPPLY MODULE OR DRIVE MODULE TERMINAL.

FOR 16 GAUGE MOTOR POWER WIRE: STRIPPED ENDS OF STRANDED WIRES MUST BE DOUBLED OVER AND FULLY TINNED FOR

PROPER CLAMPING IN DRIVE MODULE TERMINAL.

TERMINAL POST HARDWARE DETAILS:

I-SERIES MOTORS ARE USED WITH BRU-500 DRIVES ONLY.

1000

1000

DO NOT OVERTIGHTEN

USE NUT DRIVER ONLY

36 LB-IN (4.0 Nm) ABSOLUTE

MAXIMUM TIGHTENING TORQUE.

NOTES:

THE PSM MUST BE CENTERED BETWEEN THE DRIVE MODULES TO MINIMIZE THE DC BUS INDUCTANCE, SO THAT AN

EQUIVILENT NUMBER OF DRIVES ARE LOCATED ON EACH SIDE OF THE PSM.

FUSE SIZE: PSM-125-UL CLASS RK5 90 AMP (5000 AIC) A DISCONNECTING DEVICE IS REQUIRED FOR SAFETY AND MAINTENANCE.

PSM-50-UL CLASS RK5 40 AMP (5000 AIC)

NOTES ON SIZING OF POWER TRANSFORMERS AND INPUT WIRES:

a) TRANSFORMER 3 PHASE KVA = X (LINE-TO-LINE SECONDARY VOLTS RMS) X (PER PHASE SECONDARY CURRENT RMS) =

X (LINE-TO-LINE PRIMARY VOLTS RMS) X (PER PHASE PRIMARY CURRENT RMS).

b) TRANSFORMER 3 PHASE KVA = (SUMMATION OF EACH MOTORS ACTUAL AVERAGE OUTPUT POWER) X (1.2) 1.2 FACTOR ADDS 20%

AS ROUGH ESTIMATE OF DRIVE MODULE & MOTOR LOSSES.

RELIANCE MOTION CONTROL

3 PHASE TRANSFORMERS

R S T

R S T

L1 L2 L3

R S T

R S T

GROUND TERMINAL POSTS

POSITIVE,NEGATIVE TERMINAL POSTS

3

3

CAUTION