Figure 3.11 – Rockwell Automation 1394 SERCOS Interface Multi-Axis Motion Control System Installation Manual User Manual

Page 75

Publication 1394-IN002B-EN-P — February 2004

Connecting Your 1394 SERCOS Interface System

3-21

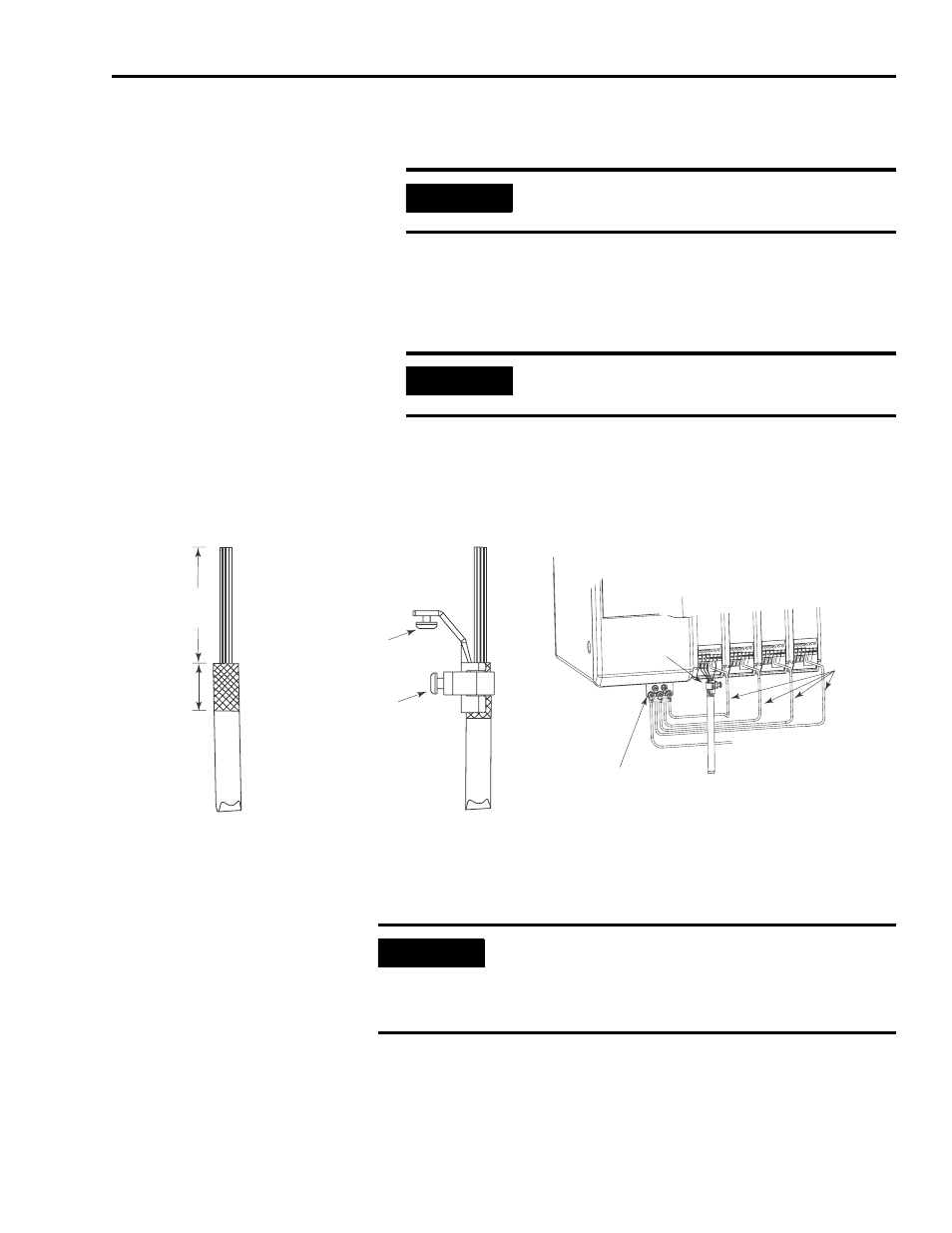

5. Remove another 22 mm (0.875 in.) of insulation to expose the

braided shield underneath for clamp attachment.

6. Position the cable shield clamp over the exposed braided shield

(ensure clamp screw is behind clamp and not braided shield).

7. Tighten the clamp screw.

8. Thread the bracket screw into the bottom of the axis module and

tighten.

Figure 3.11

Motor Power Cable Clamp Preparation

1

Dimensions given are approximate and will vary depending on the specific installation. Keep wires as short as

possible while maintaining adequate stress relief.

2

Remove plastic (captive) washer, if present.

IMPORTANT

When cutting into the insulation use care not to

cut into the braided shield underneath.

IMPORTANT

Do not overtighten the clamp screw or damage

to the braided shield may result.

Cable wires

Braided

shield

exposed

51 mm

(2.0 in.)

1

22 mm

(.875 in.)

1

Motor

cable

Bracket

screw

2

Clamp

screw

Clamp

shield

clamp

Cable Preparation

Cable Attachment

Wiring to Axis Module

System module

single point bond bar

Motor

power

cable

Axis

cable clamp

1394 Front View

To bonded

cabinet ground bus

or power distribution ground

PE1

connections

IMPORTANT

If your 1394x-AM75 axis module requires 10 mm

2

(8

AWG) cable, replace the clamp that shipped with

your axis module with catalog number 1394C-8AWG-

GCLAMP.