Bulletin 1333 heavy duty dynamic braking, Brake specifications, How to select a brake – Rockwell Automation 1333 Drive, 3/4-5HP, 230-575V Series D User Manual

Page 130

Application Data

Appendix D

D-3

Bulletin 1333

The Bulletin 1333 Adjustable Frequency Drive has the ability to let a

Heavy Duty Dynamic Braking

connected motor generate braking torque. This ability however, is limited

to approximately 20% of the drive rated braking torque. The braking

torque can be increased by adding one or more Bulletin 1333 heavy duty

dynamic braking kits to the drive. Typically the braking torque can be

increased to 100% for 20 seconds at a duty cycle of 20%.

The following evaluation can help determine if heavy duty dynamic

braking may be required for your application.

Brake Specifications

Braking Torque:

100% Torque for 20 Seconds (typical)

Duty Cycle:

20% (typical)

Input Power:

Power from Drive DC Bus

Temperature:

–10 to + 50

°

C (+14 to +122

°

F).

Humidity:

5 to 95% Non-Condensing

Atmosphere:

No Corrosive Gas or Non-Hazardous Dust

Humidity:

3,300 Feet (1,000 Meters) Maximum without Derating

Enclosure Type:

NEMA Type 1 (IP20)

How to Select a Brake

To begin selection, the following application information must be obtained.

The nameplate horsepower of the motor

HP.

The nameplate base speed of the motor

N in RPM.

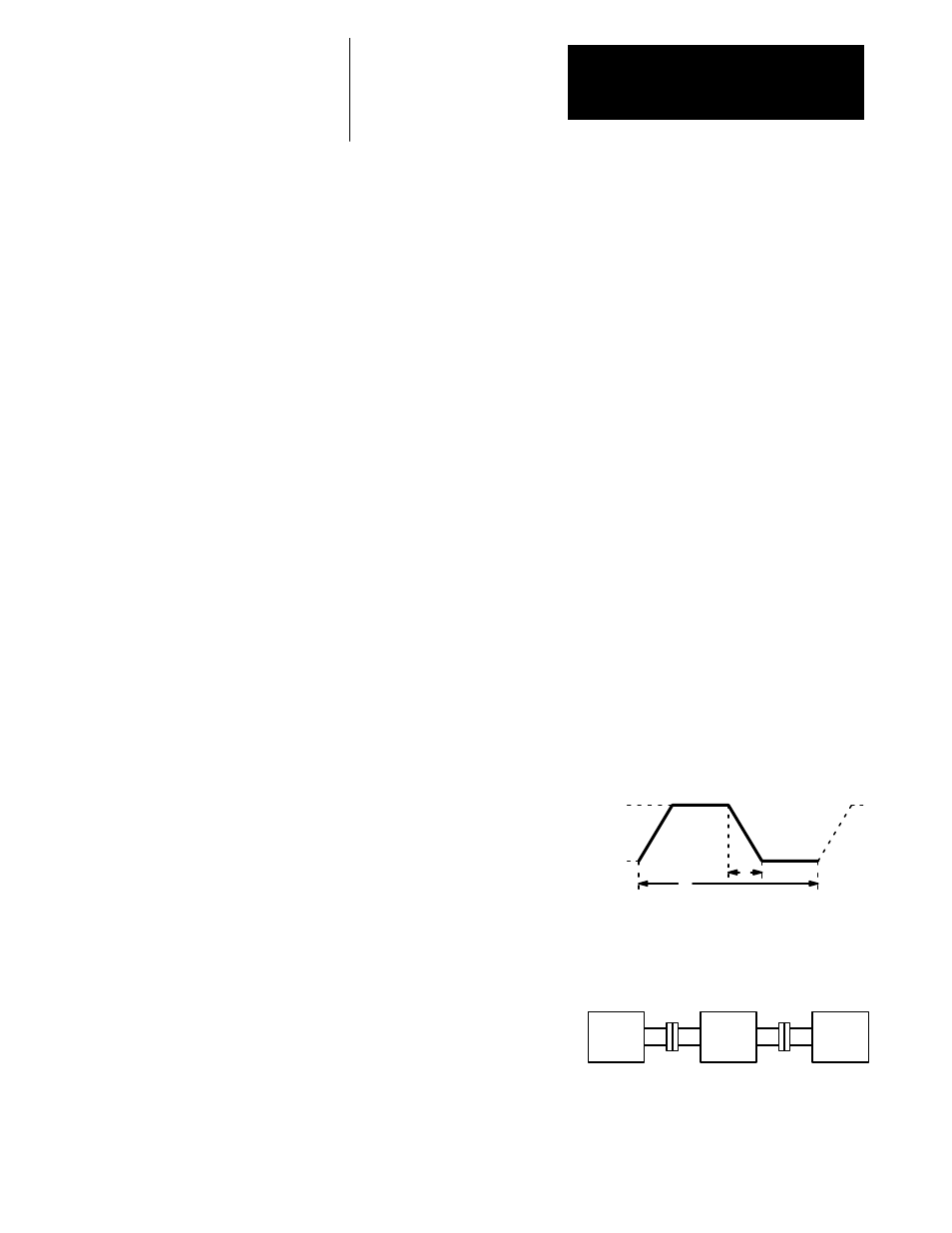

t

2

N

2

RPM

N

1

RPM

t

1

The speed profile of the motor

where:

N

1

= The motor’s minimum speed in RPM.

N

2

= The motor’s maximum speed in RPM.

t

1

= The motor’s cycle time in seconds.

t

2

= The motor’s decel time in seconds.

Motor

Inertia

wk

2M

Gear

Ratio

GR

Load

Inertia

wk

2L

Input

RPM

Output

RPM

The motor inertia,

the nameplate gear reduction

ratio, and the load inertia.