Install components – Rockwell Automation PF700 PowerFlex 700 Drive Components Replacement - Frame 9 User Manual

Page 50

50

Rockwell Automation Publication 20B-IN025B-EN-P - January 2011

Chapter 3 Component Replacement Procedures

Install Components

1.

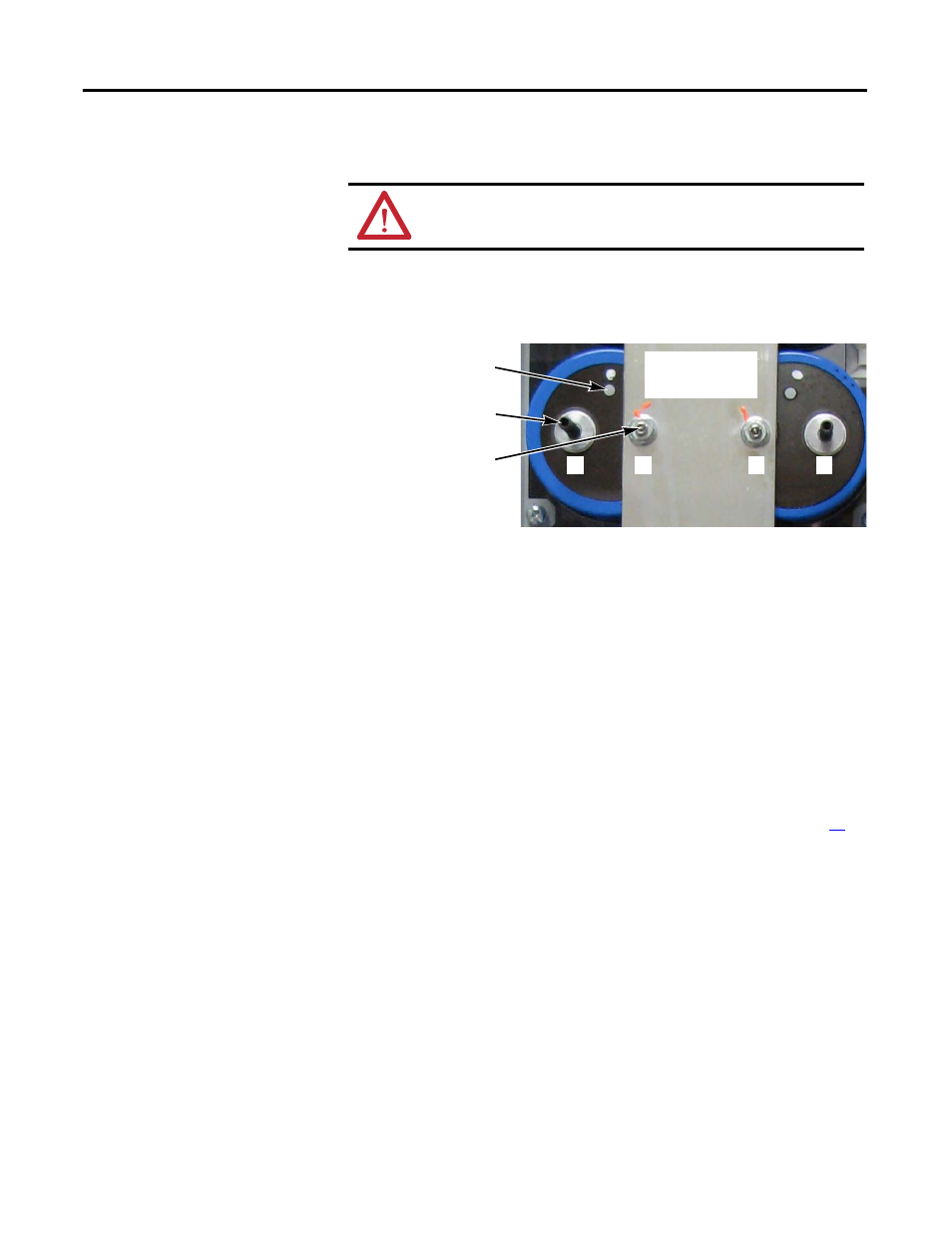

Replace setscrews for each new Capacitor using a 3 mm angle hex wrench.

Each Capacitor needs a short and long setscrew; see the illustration below

for where to install each one.

2.

Place Capacitors into correct position in drive (vent plug at top or

12 o’clock).

3.

Place Bus Capacitor Busbar onto Capacitors.

4.

Install washers and nuts onto the shorter setscrews to secure the Bus

Capacitor Busbar to the Bus Capacitors.

Note:

Install all setscrews, washers, and nuts but do not tighten yet.

5.

Place the Transitional Busbar in position, but do not install yet. Verify the

Bus Capacitor setscrews, Flexible Capacitor Busbars, and all washers and

nuts fit. Adjust as needed.

6.

Remove the Transitional Busbar, and tighten all washers and nuts for the

Bus Capacitor Busbar. Torque to 5.6 N•m (50 lb•in).

7.

Install the Transitional Busbar according to the instructions on page

32

.

8.

Reconnect all wires and connectors.

9.

Reassemble remaining components in reverse order.

10.

Replace all safety shields and enclosure covers before applying power to the

drive.

ATTENTION: Install each capacitor so its vent plug is at the top

or 12 o’clock. Component and system damage may result if you

position any Bus Capacitor incorrectly.

Capacitors shown

with Bus Capacitor

Busbar installed

Vent Plug (must be at

top or 12 o’clock)

Longer Setscrew for

Transitional Busbar

Shorter Setscrew for

Bus Capacitor Busbar

–

+

–

+