Fastener torque specifications, Torque sequence – Rockwell Automation PF700 PowerFlex 700 Drive Components Replacement - Frame 9 User Manual

Page 17

Rockwell Automation Publication 20B-IN025B-EN-P - January 2011

17

Component Diagrams and Torque Specs Chapter 1

Fastener Torque

Specifications

Torque Sequence

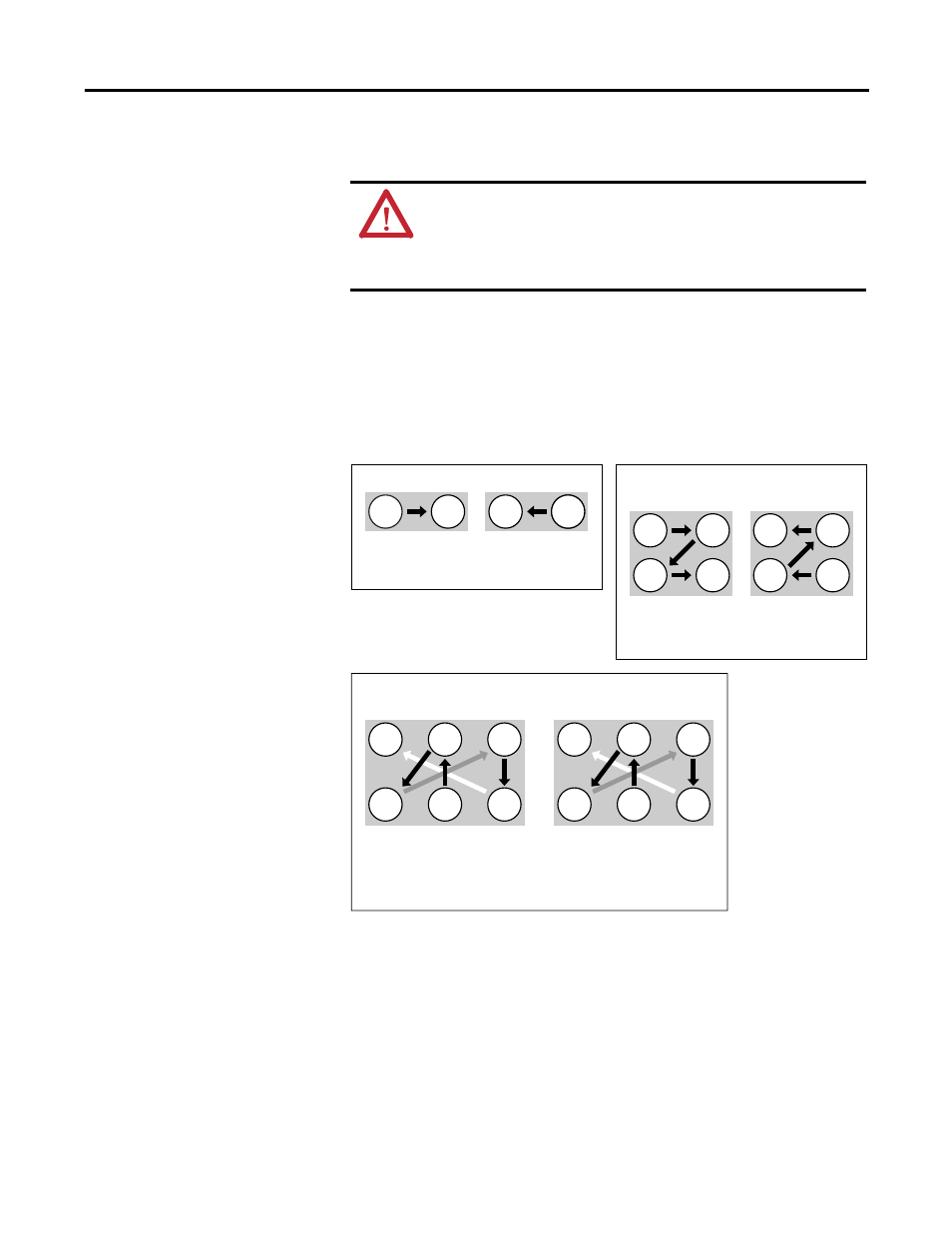

Figure 6 illustrates initial and final tightening sequences for components fastened

to a heat sink using two, four, and six screws. Initial torque is one-third (33.3%) of

final torque, except six-point mountings, which require 0.7 N•m (6 lb•in.) The

numeric illustration labels are for your assistance. Drive components do not carry

these labels.

Figure 6 - Various-Point Mounting

ATTENTION: When mounting components to a drive’s heat sink,

component fastener torque sequences and tolerances are crucial

to component-to-heat sink heat dissipation.

Components can be damaged if initial tightening procedure is not

performed to specification.

Initial

Torque Sequence

Final

Torque Sequence

Two-Point Mounting

Start

End

End

Start

1

2

1

2

Initial

Torque Sequence

Final

Torque Sequence

Four-Point Mounting

End

Start

Start

End

1

2

4

3

3

4

2

1

Note: Do not exceed 0.7 N•m (6 lb•in) on initial torque.

Initial Torque Sequence

Six-Point Mounting

Start

End

Final Torque Sequence

Start

End

6

2

3

1

4

5

6

2

3

1

4

5