Torque specifications – Rockwell Automation PF700 PowerFlex 700 Drive Components Replacement - Frame 9 User Manual

Page 18

18

Rockwell Automation Publication 20B-IN025B-EN-P - January 2011

Chapter 1 Component Diagrams and Torque Specs

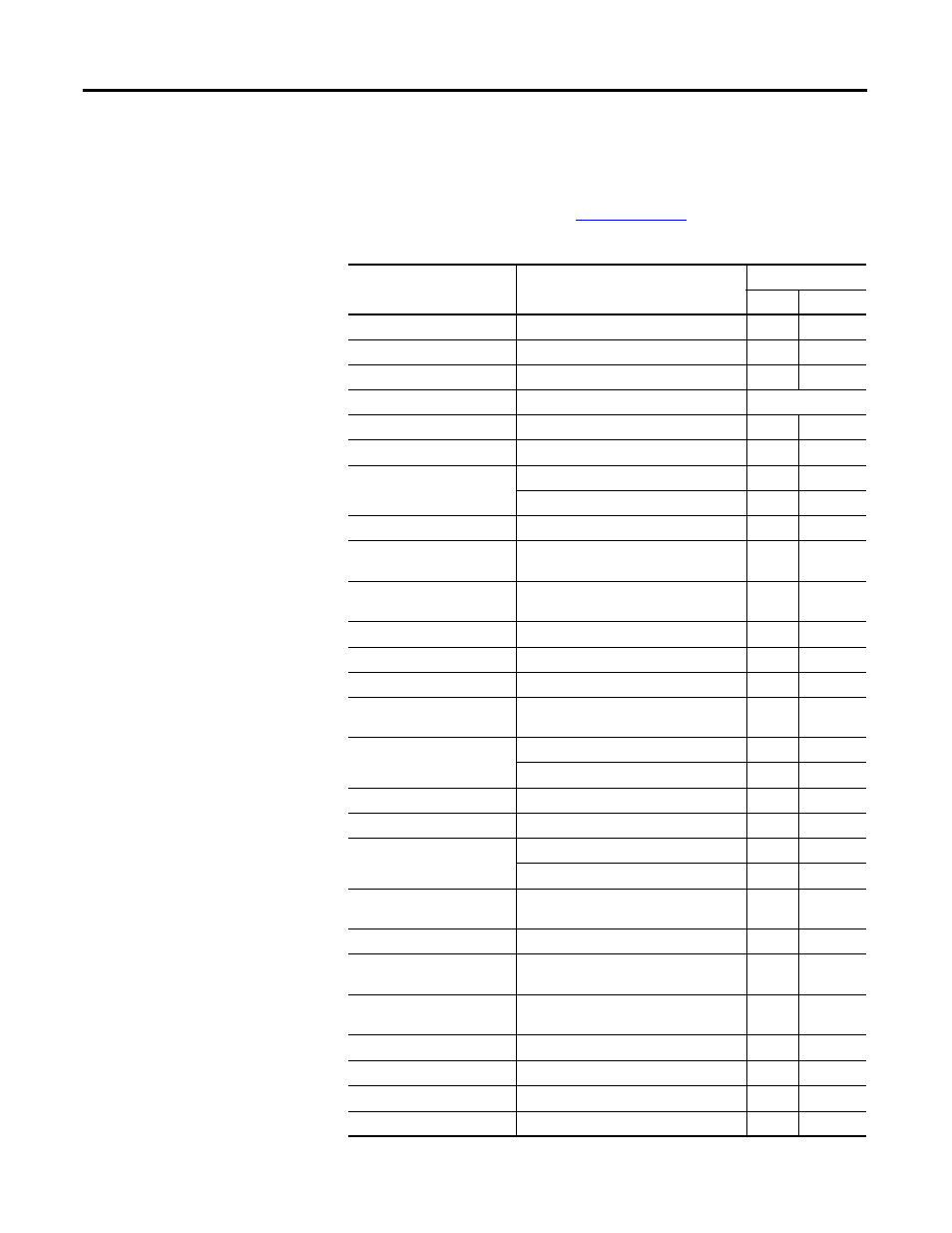

Torque Specifications

The following table lists fastener locations by component, how the fasteners are

used, and torque specifications. See

in this chapter for fastening

two-point, four-point, and six-point components to the heat sink.

Torque

Component Fastener

Application

lb•in

N•m

Fan Motor

Motor to Fan Cover Assembly

14

2

Fan Cover Assembly

Assembly to chassis

26

3

Fan Transformer

Transformer to chassis

26

3

Fan Capacitor

Capacitor to chassis

Hand tighten

MOV Surge Suppressor

MOV to chassis

14

2

Converter Snubber Board

Board to Input Rectifier

50

6

Balancing Resistor

Resistor to heat sink

Initial sequence:

6

0.7

Final sequence:

26

3

Balancing Resistor

Wires to Capacitor Busbar Assembly

50

6

Converter Heatsink Thermal

Sensor

Thermistor to heatsink

14

2

Main Control Panel Thermal

Sensor

Thermistor to mounting bracket

14

2

Bus Capacitor Holder

Holder to Bus Capacitors

26

3

Capacitor Busbar Assembly

Assembly to Bus Capacitors

50

6

Gate Interface Board

Board to Power Modules

14

2

Inverter Power Module (IGBT)

Busbar

Busbar to Power Modules

80

9

Inverter Power Module (IGBT)

Module to heat sink

Initial sequence:

6

0.7

Final sequence:

32

3.6

DIN Rail (TB1)

Rail to chassis

50

6

PE Shortening Bar

Bar to TB1

80

9

Converter Power Module (SCR)

SCR to heat sink

Initial sequence:

6

0.7

Final sequence:

50

6

Transitional Busbar Assembly

Assembly to Power Module Busbar

Assembly

80

9

DC Bus Inductor L1

Inductor to chassis

50

6

Busbar Cable Adaptor

Adaptor to Transitional Busbar and DC Bus

Inductor

80

9

Converter Bus and Motor

Busbars

Busbars to all connections

80

9

Wires (PE)

Wires to Ground Stud

80

9

Wires Wires

to

TB1

80

9

Wire (TE)

Wire to TB1

50

6

Wires Wires

to

TB2

7

0.8