Care and use manual – Waters IC-Pak Column and Guard User Manual

Page 2

[ Care and Use ManUal ]

IC-Pak Column and Guard Column

2

Table 2: Cation Column Characteristics

The packing material is a styrene divinylbenzene resin with a

sulfonic acid functional group. The columns are shipped in 2 mM

nitric acid.

II. InstallatIon

Before attaching the column in the flow path:

1. Directly connect the HPLC injector to the detector by replacing the old

column with a zero-dead-volume union.

2. Flush the lines free of microparticulates and previous solvents. Flush

the injector loop if applicable.

3. Remove the union.

4. Install the column.

a. Installing a Stainless Steel Column

Remove the end plugs from the column and save them for use when

the column is removed from the system and stored. The column

outlet is indicated by an arrow on the label (showing the direction

solvent should flow).

To install the column, thread the inlet and outlet fittings into the

column until finger tight, and then tighten the fittings 1/4-to-1/2

turn. Do not over-tighten. Over-tightening will damage the

connection. A properly prepared and assembled compression fitting

in good condition is all that is required.

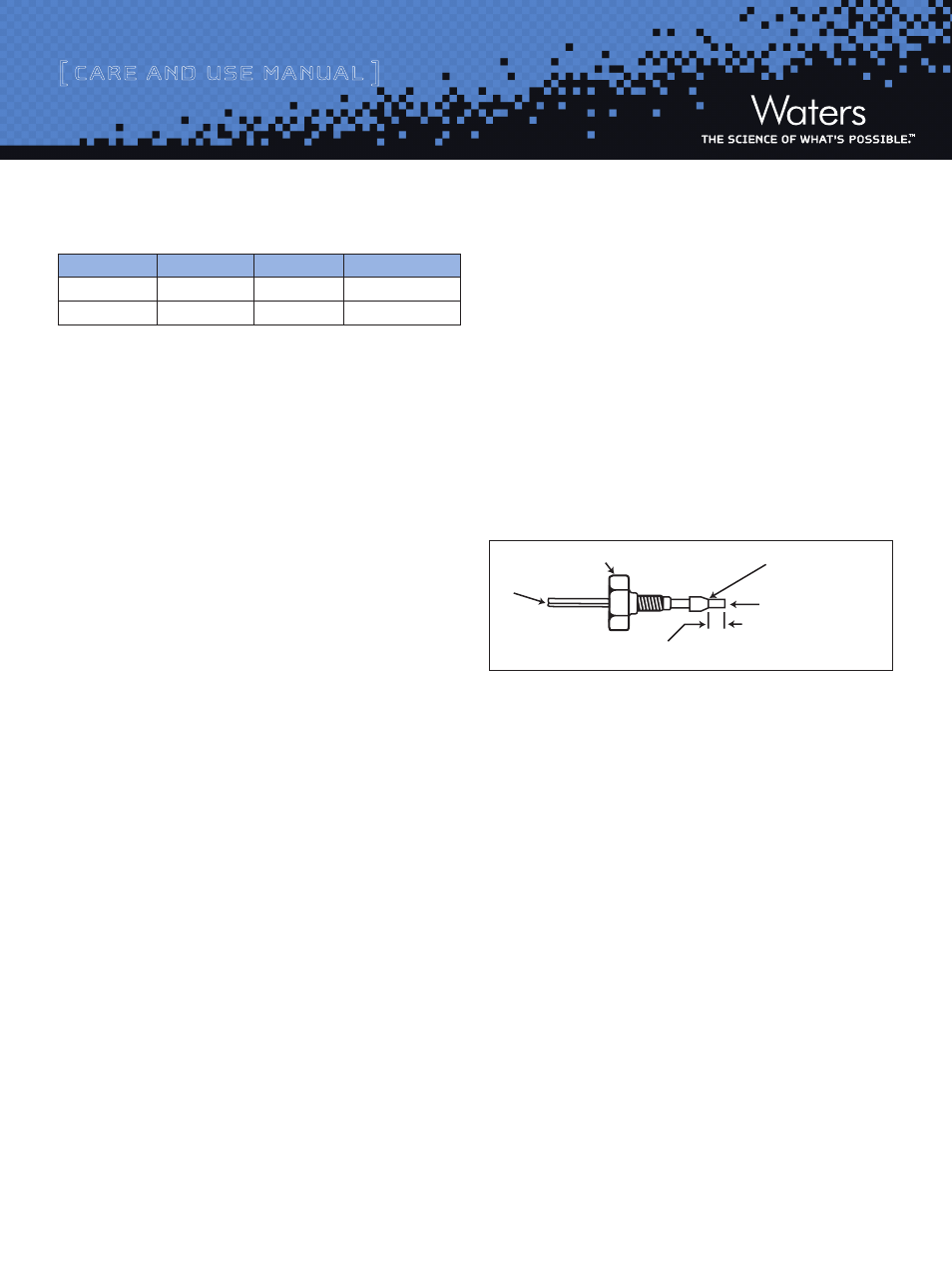

Prepare a new tubing/ferrule connection (Figure 1) when a new

column is connected or when a damaged compression screw or worn

ferrule are removed.

Note: The tubing distance beyond the ferrule may differ for different

column types. Re-size the tubing to the correct distance by replacing

the ferrule.

To prepare a new tubing/ferrule connection:

1. Scribe the circumference of the tubing at the desired break using either

a file with a cutting edge or a tube cutter.

2. Grasp the tubing on both sides of the scribe mark with cloth-covered

pliers (to prevent marring the tube surface), and gently work the tube

back and forth until it separates.

Note: Ensure that the tubing end is straight, open, and free of burrs.

3. Slide the compression fitting, followed by the ferrule (large end of the

taper first) over the tube.

Note: Properly bottom the tubing in the fitting seat. Otherwise, dead

volume could result in sample band spreading.

Figure 1: Ferrule and Compression Assembly (Stainless Steel Column)

b. Installing Non-Metallic Columns

Remove the end plugs from your column and save them for use when

the column is removed from the system and stored. The column

outlet is indicated by an arrow on the label (showing the direction

solvent should flow).

To install the column, thread the inlet and outlet fittings into the

column until finger tight, and then tighten the fittings 1/4-to-1/2

turn. Use caution with non-metallic columns. Over-tightening these

fittings may cause damage which results in a leaking connection.

A properly prepared and assembled compression fitting in good

condition is all that is required.

Cation Column

Dimensions

Particle Size

Capacity

IC-Pak C

4.6 x 50 mm

10 µm

12.0 ± 0.2 µeg/mL

Guard

4.6 x 50 mm

n/a

2.0 ± 0.2 meg/mL

COMPRESSION SCREW OR NUT

TUBE

FERRULE

END MUST BE STRAIGHT

AND SMOOTH TO ACHIEVE

MAXIMUM COLUMN EFFICIENCY

CRITICAL DISTANCE TO BE DETERMINED BY

THE UNION OR COLUMN FITTING, ETC.