Warning – MacDon D60 Draper Headers User Manual

Page 57

SECTION 7. OPERATION

Form 169441

55

Revision B

7.14 DOUBLE WINDROWING

The 25 FT. to 40 FT. D60 Harvest Headers

double windrow capability allows cutting one

round delivering to the right end (A), then shifting

to left end delivery (B) and laying the second

windrow beside the first.

NOTE

The

end

delivery

opening

size

(67 in. (1710 mm)) is designed to give

minimal clearance between the first

windrow laid and the standing crop.

The center delivery opening size from

the factory is 74 in. (1870 mm), with an

adjustable range of 61 - 78 in.

(1540 - 1970 mm).

NOTE

If end delivery with a 30 FT. header

equipped with transport, crop can

interfere with the outboard wheel. To

rectify the problem, remove the

outboard wheel.

Larger capacity combines or forage harvesters

can then pick up twice as much material in a

single pass - saving time and fuel.

The decks can be shifted manually or

hydraulically.

7.14.1

HYDRAULIC DECK SHIFT

The hydraulic deck shift feature allows the

Operator to select center, left, or right delivery

from the windrower cab.

It is only available on the 25, 30, 35, and 40 FT.

D60 Harvest Headers.

Refer to your Self-Propelled Windrower

Operator's Manual for identification and operation

of the deck shift control.

7.14.2

MANUAL DECK SHIFT

Both decks can be shifted manually, and can be

positioned to deliver the crop from the right or left

end, and the center.

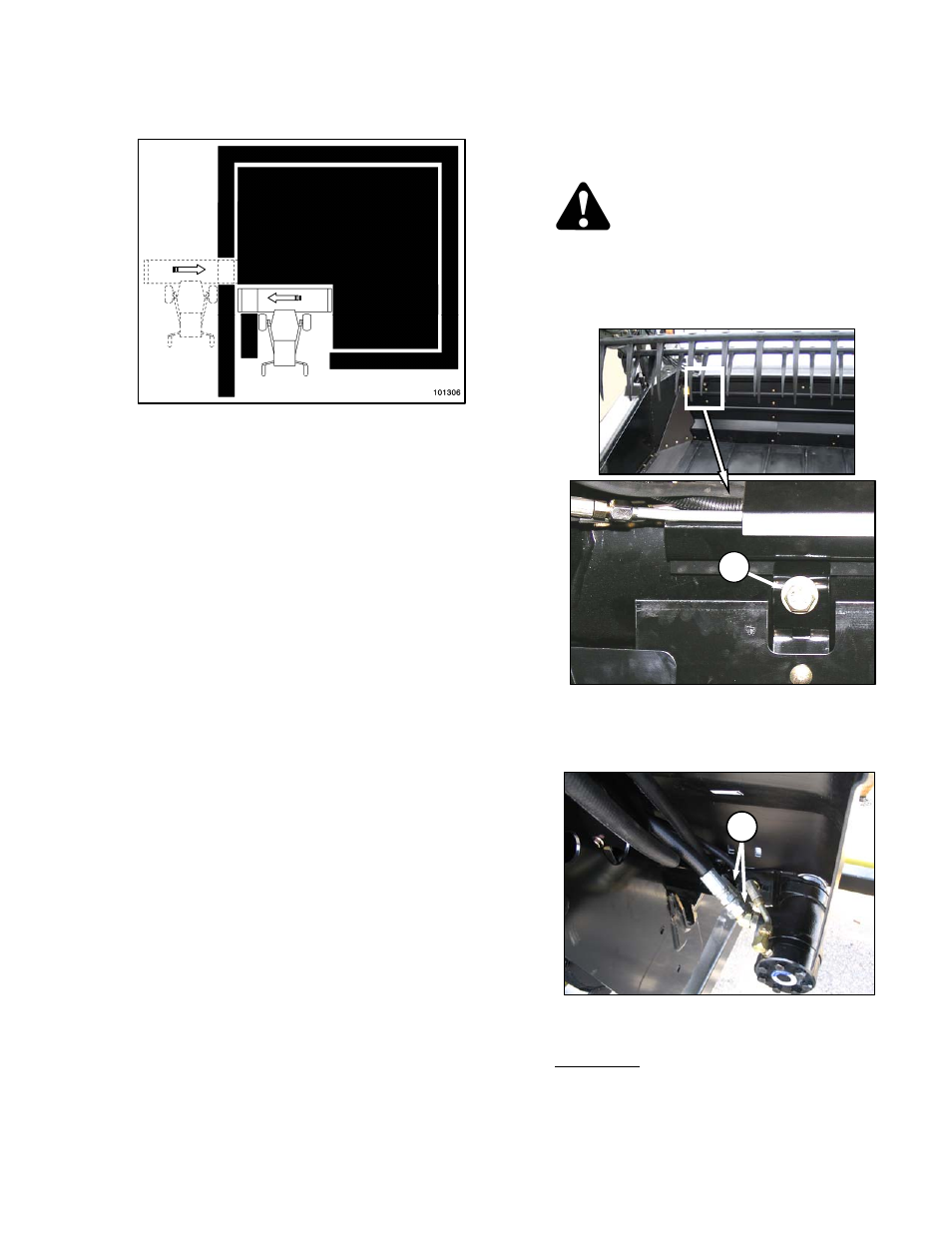

WARNING

Stop windrower engine, and remove key

before making adjustments to machine. A

child or even a pet could engage the drive.

a. Loosen bolt (A) on the deck that is to be moved.

b. Slide deck to close off the center opening. Re-

tighten bolt (A).

c. Reverse the draper drive motor hoses (B) on the

moved deck so that the draper turns the same

direction as the existing deck.

(Continued next page)

A

B

A

LEFT DECK MOTOR

B