MacDon D60 Draper Headers User Manual

Page 107

SECTION 8. MAINTENANCE AND SERVICING

Form 169441

105

Revision B

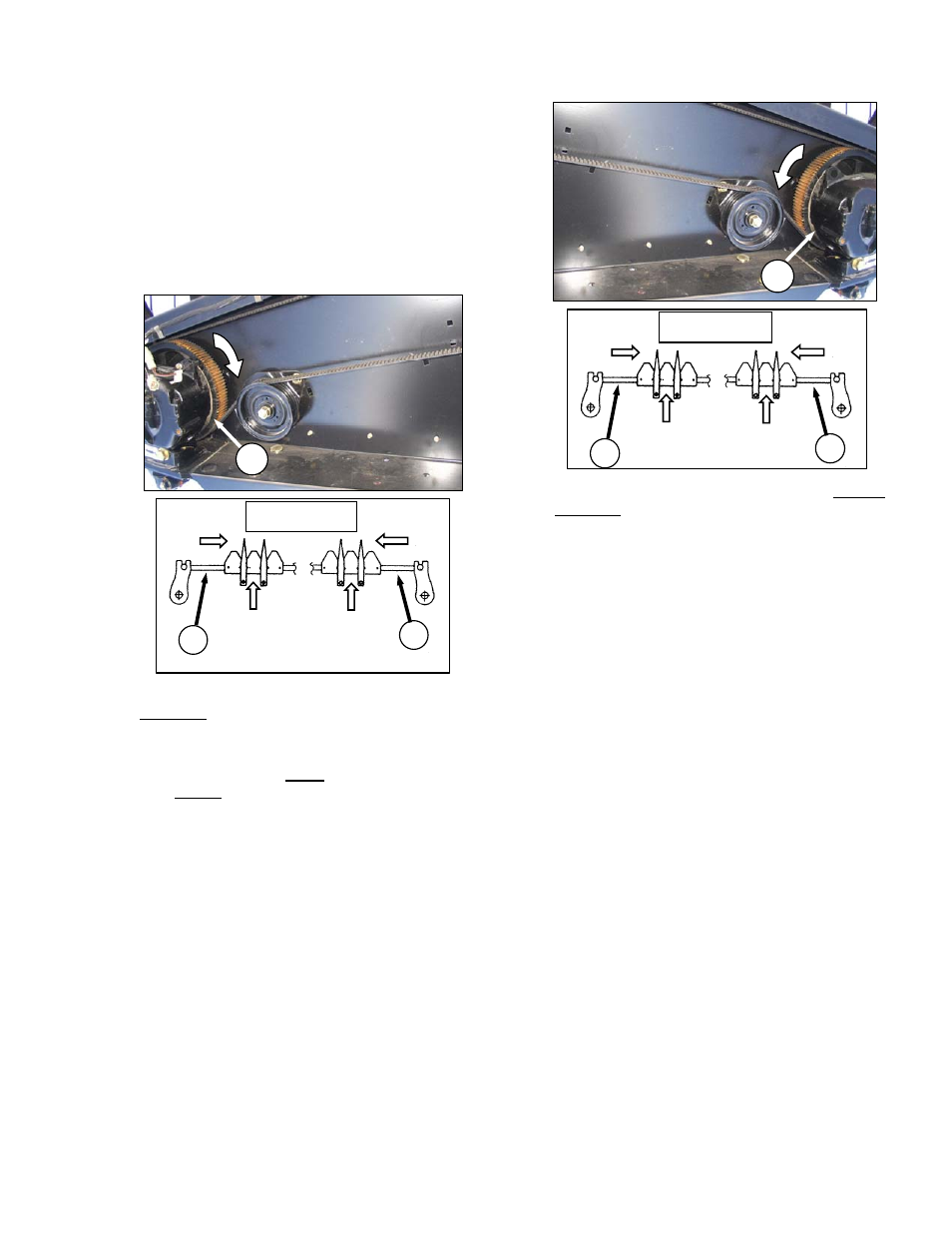

8.7.9.3 Sickle

Drive

Timing

Double knife D60 Harvest Headers 35 FT. and

smaller require that the sickles are properly timed

to move in opposite directions.

To adjust the sickle timing, proceed as follows:

a. Remove the right sickle drive belt. Refer to

Section 8.7.9.2.2 Removal - Right End Timing

Belt.

b. Rotate the left wobble box driven pulley (A)

clockwise until the left sickle (B) is at the center of

the inboard stoke (moving towards center of

header).

NOTE

Center stroke is when the sickle

sections are centered between guard

points as shown.

c. Rotate the right wobble box pulley (C) counter

clockwise until the right sickle (D) is at the center

of the inboard stroke.

d. Install the right wobble box drive belt, and adjust

tension. Refer to Section 8.7.9.2.3 Installation -

Right End Timing Belt.

IMPORTANT

To maintain timing, wobble box driver

and driven pulleys must not rotate as

the belt is tightened.

e. Check that the timing belts are properly seated in

the grooves on both driver and driven pulleys.

f. Check for correct sickle timing by rotating the

drive slowly by hand, and observe sickles where

they overlap at the center of the header.

IMPORTANT

Sickles must move in opposite

directions, and must begin moving at

exactly the same time.

If timing is off, proceed as follows:

1. Loosen right belt sufficiently to allow skipping

the belt one or more teeth as required. Refer

to Section 8.7.9.2.1 Tension Adjustment -

Timing Belt.

2. If right sickle “leads” left sickle, rotate RIGHT

SIDE driven pulley (C) clockwise.

3. If right sickle “lags” left sickle, rotate RIGHT

SIDE driven pulley (C) counter clockwise.

4. Tighten right belt.

RIGHT

SICKLE

LEFT

SICKLE

DIRECTION OF

MOVEMENT

SECTIONS CENTERED

BETWEEN GUARDS

B

D

A

RIGHT

SICKLE

LEFT

SICKLE

DIRECTION OF

MOVEMENT

SECTIONS CENTERED

BETWEEN GUARDS

B

D

C