MacDon D60 Draper Headers User Manual

Page 142

SECTION 8. MAINTENANCE AND SERVICING

Form 169441

140

Revision B

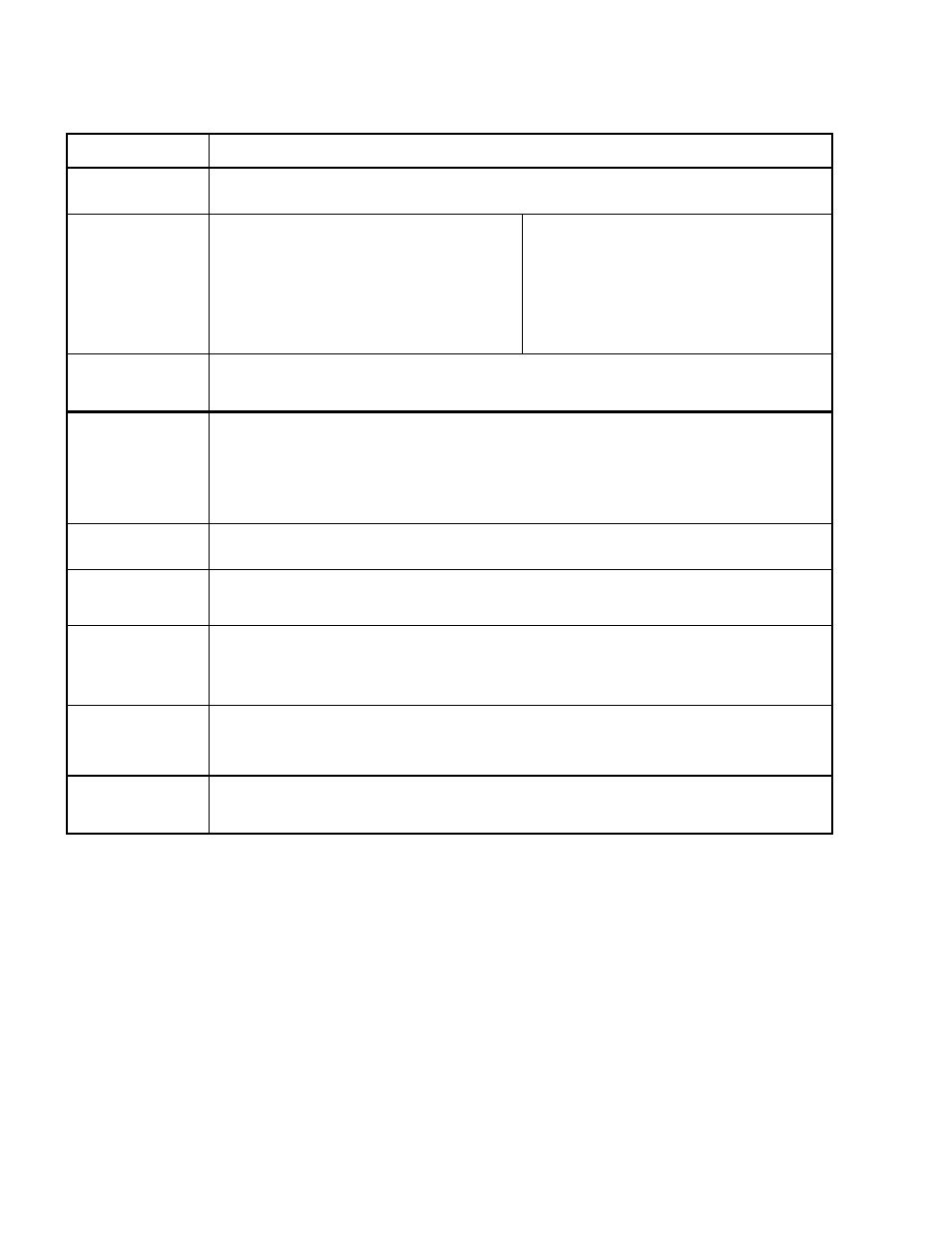

8.11.2

INTERVAL MAINTENANCE

INTERVAL SERVICE

FIRST USE

Refer To Section 8.11.1 BREAK-IN INSPECTIONS (previous page).

100 HOURS OR

ANNUALLY *

1. Check Wobble Box Mounting Bolts.

2. Check Wobble Box Lubricant Level.

3. Check Sickle Drive Belt Tension.

4. Check Transport Wheel Bolt Torque

(Option).

5. Check Reel Tine To Cutterbar

Clearance.

6. Check Reel Drive Chain Tension.

7. Grease Reel Drive Chain.

8. Grease Upper Cross Auger RH

Support (Option).

9. Lubricate

Hydraulic

Couplers.

END OF

SEASON

Refer To Section 7.22 STORAGE.

10 HOURS OR

DAILY

1. Check Hydraulic Hoses And Lines For Leaks.

2. Check Stabilizer/Transport Wheels Tire Pressure.

3. Check Sickle Sections, Guards, And Hold-Downs.

4. Oil Sickle (Except In Sandy Conditions).

25 HOURS

1. Grease Sickle Head.

50 HOURS

1. Grease Sickle Drive Shaft Bearings (Double Knife).

2. Grease Draper Roller Bearings.

250 HOURS OR

ANNUALLY *

1. Grease Transport Axle Pivot Bushings (Option).

2. Grease Split Reel U-Joint.

3. Grease Upper Cross Auger Center Support (30 FT. and Up - Option).

500 HOURS OR

ANNUALLY*

1. Grease Transport/Stabilizer Wheel Hub Bearings.

2. Grease Reel Shaft Bearings.

1000 HOURS OR

3 YEARS

1. Change Wobble Box Lubricant.

* IT IS RECOMMENDED THAT ANNUAL MAINTENANCE BE DONE PRIOR TO START OF OPERATING

SEASON.