Caution – MacDon D60 Draper Headers User Manual

Page 108

SECTION 8. MAINTENANCE AND SERVICING

Form 169441

106

Revision B

8.7.10 WOBBLE

BOX

CAUTION

To avoid personal injury, before servicing

machine or opening drive covers, follow

procedures in Section 8.1 PREPARATION

FOR SERVICING.

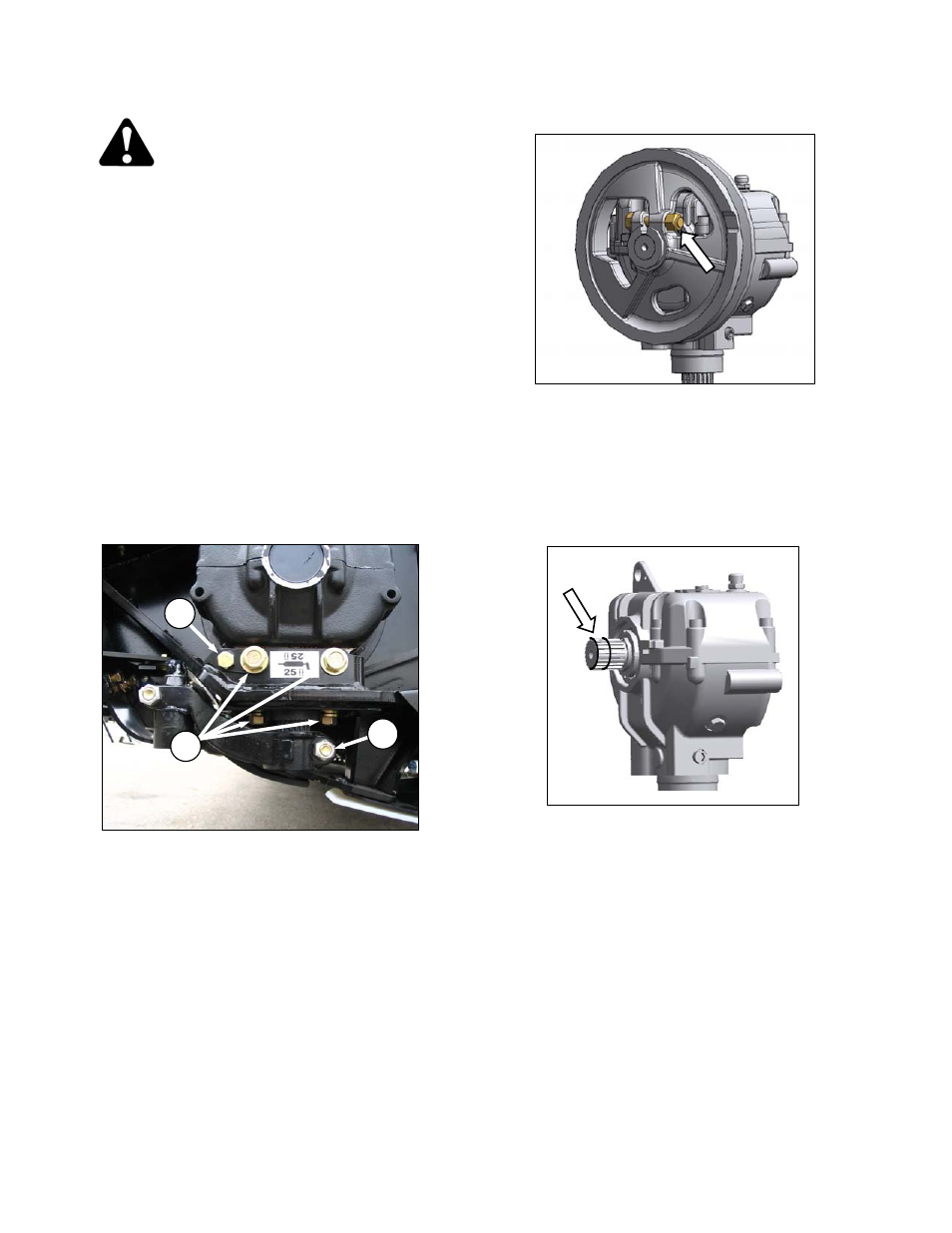

8.7.10.1 Mounting Bolts

Check four wobble box mounting bolts (B) torque

after the first 10 hours operation, and every 100

hours thereafter. Torque should be 200 ft·lbf

(270 N·m). When tightening, start with the side

mounting bolts.

8.7.10.2 Wobble Box Removal

a. Loosen sickle drive belt, and slip off wobble box

pulley. Refer to Section 8.7.8 Sickle Drive Belts -

Non-Timed Drive and 8.7.9 Sickle Drive Belts -

Timed Drive.

b. Remove sickle head pin. Refer to Section 8.7.2

Sickle Removal, steps a. and b.

c. Remove bolt (A) from pitman arm.

d. Remove pitman arm from wobble box shaft.

e. Remove bolts (B) attaching wobble box to frame.

IMPORTANT

Do not remove or loosen locating tab

(C). This is a factory adjustment.

f. Remove

wobble

box.

8.7.10.3 Pulley Removal

a. Loosen nut and bolt from pulley.

b. Remove pulley using a 3-jaw puller.

8.7.10.4 Pulley Installation

a. Remove any rust or paint from shaft and pulley

splines. For replacement parts, remove oil/grease

with degreasing agent.

b. Apply Loctite® #243 adhesive (or equivalent) to

spline. Apply in two bands around shaft as

shown, with one band at end of spline, and one

band approximately “mid-way”.

c. Install pulley on shaft until flush with end of shaft,

and secure with bolt and nut. Torque bolt to

160 ft·lbf (217 N·m).

A

B

C