Troubleshooting (pump continued)/control box – Multiquip AP6 Series User Manual

Page 77

AP6/AP8 SERIES TRASH PUMPS • OPERATION AND PARTS MANUAL — REV. #0 (06/11/14) — PAGE 77

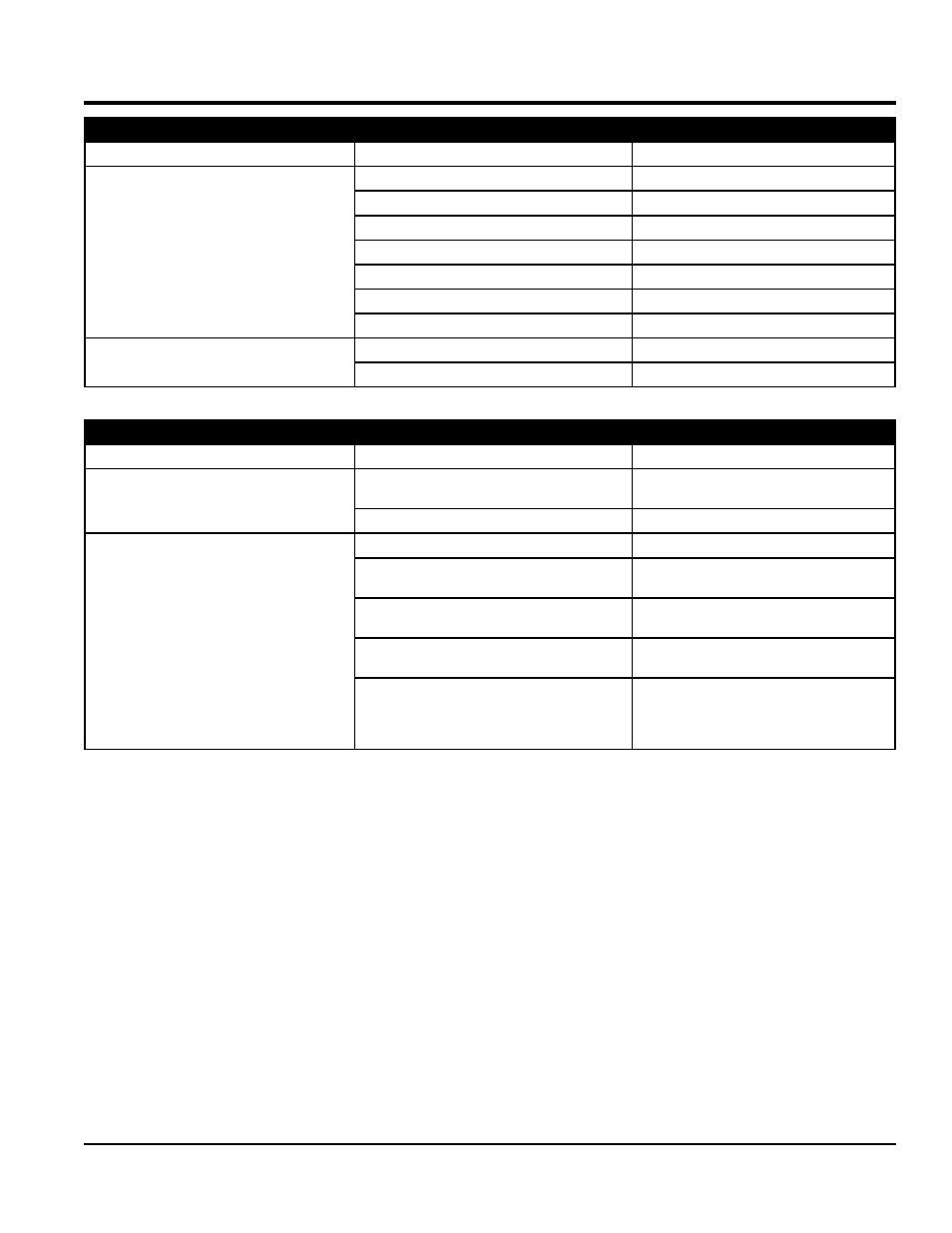

TROUBLESHOOTING (PUMP CONTINUED)/CONTROL BOX

Troubleshooting (Pump Continued)

Symptom

Possible Problem

Solution

Premature mechanical seal failure

Inadequate lubrication?

Regrease or refi ll with oil

Loss of lubrication?

Check/replace lip seal

Piping not properly supported?

Provide suitable bracing and supports

Cavitation (improper suction design)?

Correct suction problems

Misalignment?

Align all rotating parts

Discharge head too high?

Lower if possible or select large piping

Incompatibility with fl uid being pumped?

Check pumping fl uid properties

Fluid Discharging

Float obstructed or damaged?

Clean or replace.

Priming chamber bumper obstructed or worn? Clean or replace.

Troubleshooting Control Box

Symptom

Possible Problem

Solution

Control system does not perform self test

Tripped overcurrent protection?

Correct fault, replace or reset overcurrent

protection

Faulty connection to battery?

Check battery connections

Control system performs normal self test,

engine cranks, runs and shuts down

Only Battery LED illuminated

Check battery connections

Only Oil Pressure LEDIlluminated

Correct low oil pressure condition or faulty

switch, correct wiring fault

Only Temperature LEDIlluminated

Correct overheating condition or faulty

switch, correct wiring fault

Only Aux LED Illuminated? If applicable

Correct fault condition (i.e. v-belt, coolant

level) or faulty switch, correct wiring fault

All normally closed shutdowns illuminate for

one second (control system reset)?

Add suppressor diodes, protect from nearby

lightening strikes, shield induced spikes

from other equipment, add electric motor

control relay