Maintenance (trailer) – Multiquip AP6 Series User Manual

Page 58

PAGE 58 — AP6/AP8 SERIES TRASH PUMPS • OPERATION AND PARTS MANUAL — REV. #0 (06/11/14)

MAINTENANCE (TRAILER)

The following trailer maintenance guidelines are intended

to assist the operator in preventive maintenance.

TRAILER BRAKES

Properly functioning brake shoes and drums are essential

to ensure safety. The brakes should be inspected the first

200 miles of operation. This will allow the brake shoes and

drums to seat properly. After the first 200 mile interval,

inspect the brakes every 3,000 miles. If driving over rough

terrain, inspect the brakes more frequently.

ELECTRIC BRAKES

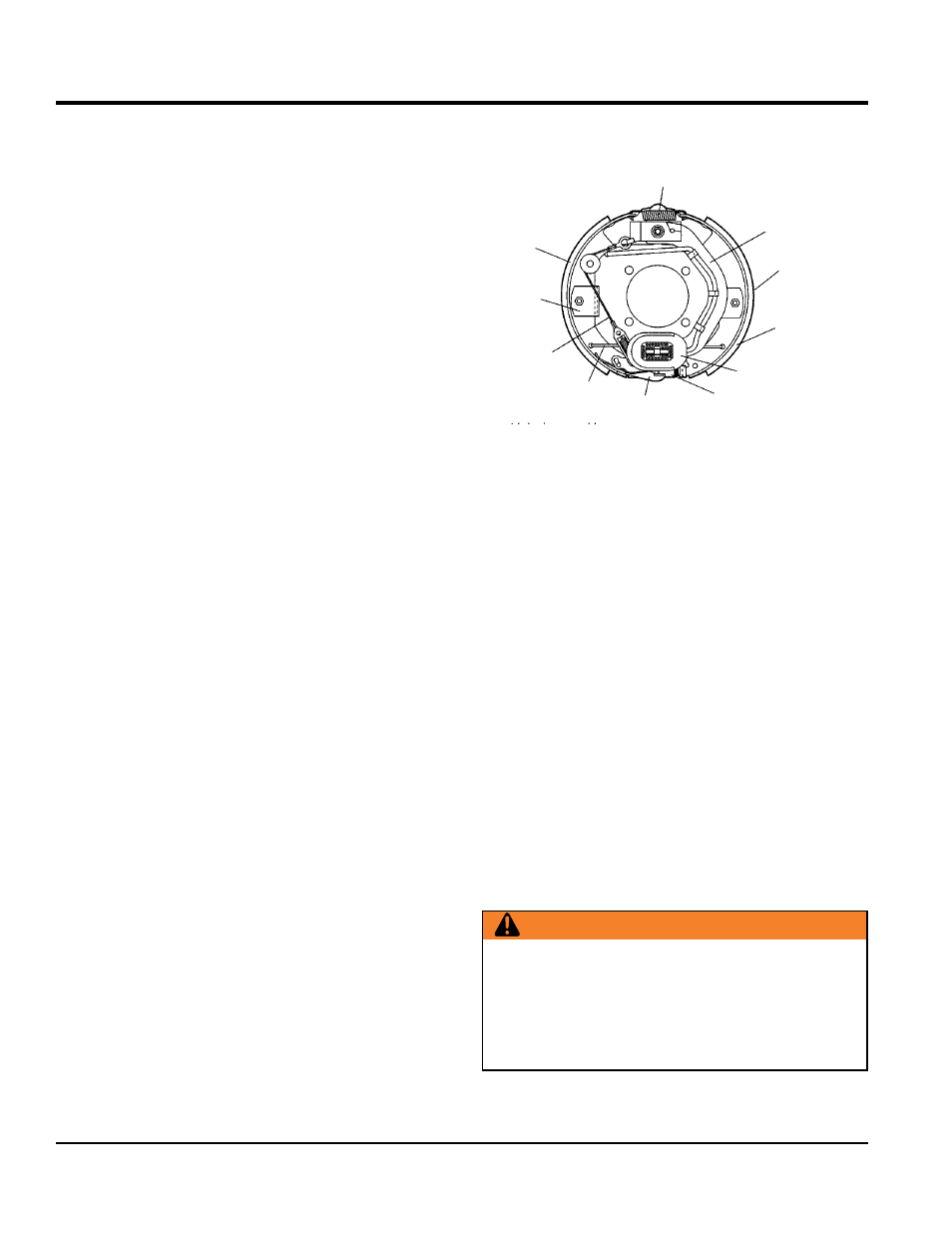

Electrically actuated brake (Figure 55) are similar to

hydraulic brakes. The basic difference is that hydraulic

brakes are actuated by an electromagnet. Listed below

are some of the advantages that electric brakes have over

hydraulic brakes:

Brake system can be manually adjusted to provide the

corrected braking capability for varying road and load

conditions.

Brake system can be modulated to provide more or less

braking force, thus easing the brake load on the towing

vehicle.

Brake system has very little lag time between the time

the vehicle’s brakes are actuated and the trailer’s brakes

are actuated.

Brake system can provide an independent emergency

brake system.

Remember in order to properly synchronize the tow vehicle’s

braking to the trailer’s braking, can only be accomplished

by road testing. Brake lockup, grabbiness or harshness is

due to lack of synchronization between the tow vehicle and

the trailer being towed or under-adjusted brakes.

Before any brake synchronizations adjustments can be

made, the trailer brakes should be burnished-in by applying

the brakes 20-30 times with approximately a 20 mph

decrease in speed, e.g. 40 mph to 20 mph.

Allow ample time for brakes to cool between application.

This allows the brake shoes to slightly be seated into the

brake drum surface.

Figure 55 displays the major electric brake components that

will require inspection and maintenance. Please inspect

Figure 55. Electric Brake Component

BREAKAWAY BRAKE

Breakaway Battery

This battery supplies the power to operate the trailer brakes

if the trailer uncouples from the tow vehicle. Be sure to

check, maintain and replace the battery according to the

battery manufacturer instructions.

Breakaway Switch

This switch causes the breakaway battery to operate the

electric brakes if the trailer uncouples from the tow vehicle.

The pull cable for the pull pin is connected to the tow vehicle,

and the switch is connected to the trailer.

To check for proper functioning of the switch, battery and

brakes, you must pull the pin from the switch and confirm

that the brakes apply to each wheel. You can do this by

trying to pull the trailer with the tow vehicle, after pulling

the pin. The trailer brakes may not lock, but you will notice

that a greater force is needed to pull the trailer.

Secondary Shoe

Hold Down

Washer

Self-Adjusting

Cable

Adjuster Spring

Adjuster Lever

Adjuster Assembly

Magnet

Primary Shoe

Backing Plate

Actuating Lever

Retractor Spring

WARNING

If electric breakaway brakes do not operate when trailer

is uncoupled from the tow vehicle, death or serious

injury can occur.

Check emergency breakaway brake system

BEFORE

each tow.