Float switches (auto mode), Mechanical float switch, How it works – Multiquip AP6 Series User Manual

Page 26: Pumping range, Design features

PAGE 26 — AP6/AP8 SERIES TRASH PUMPS • OPERATION AND PARTS MANUAL — REV. #0 (06/11/14)

FLOAT SWITCHES (AUTO MODE)

Mechanical Float Switch

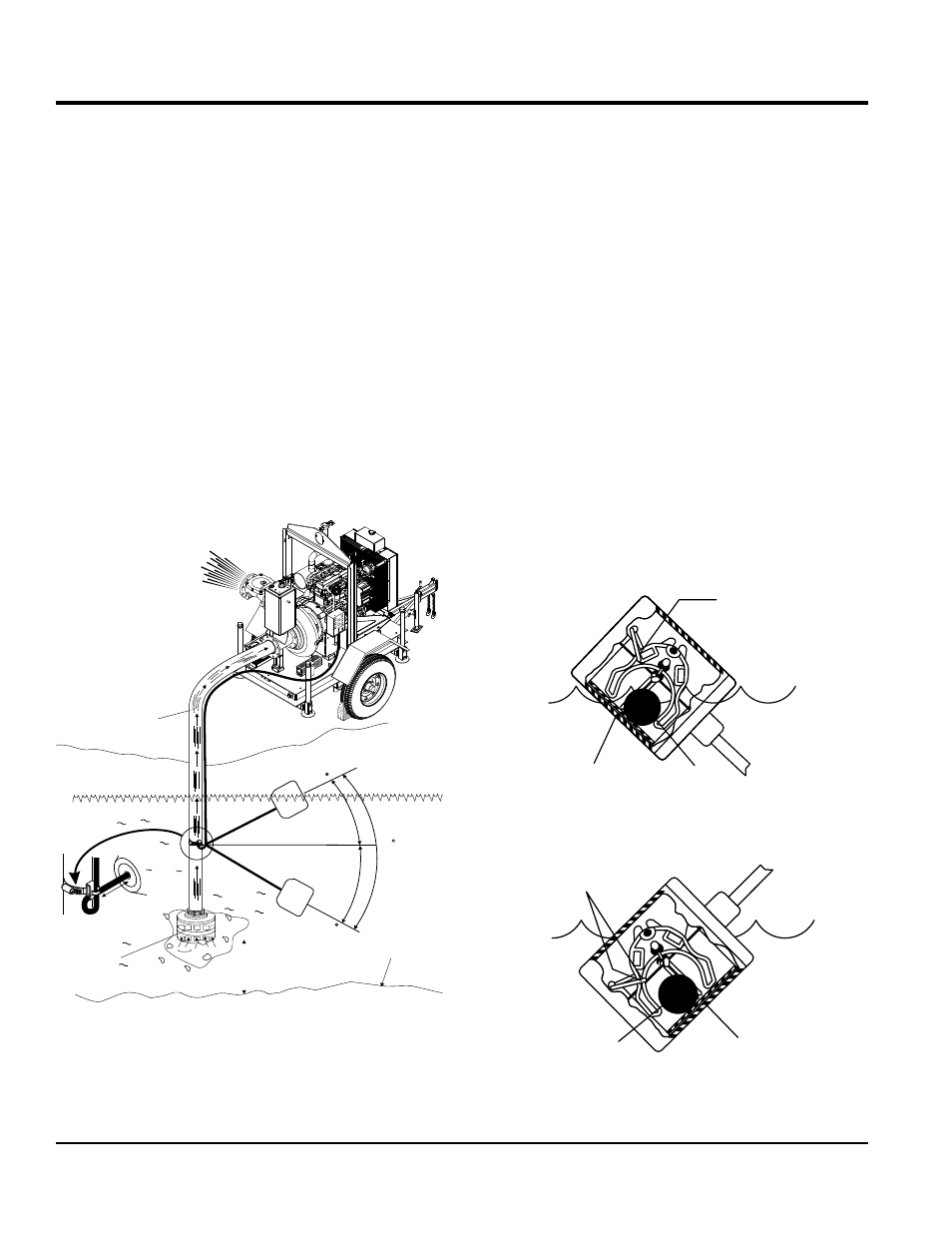

For unattended operation of the pump two mechanically

activated float switches will be required. These float

switches can be connected directly to EP250 control box

via a 4-pin connector located at the rear of the control box.

When the pump is placed in

AUTO mode, the float switches

will allow the pump to start and stop depending on the

length of the tether.

How It Works

The mechanical float switch control will turn

ON (closes)

when the float tips 45° above horizontal, indicating a high

level. It turns

OFF (opens) when the float switch drops

45° below horizontal. Reference Figure 12 and Figure 13.

Maximum pumping range is 120 degrees. See Figure 11

below.

Figure 11. Pumping Range (Float Switch)

SUCTION HOSE

STRAINER

BOTTOM

SURFACE

DO NOT LAY

STRAINER ON

BOTTOM SURFACE

PUMP

ON

60

60

120

PUMP

OFF

3.5 in. (9 cm.)

MINIMUM

TETHER

LENGTH

Pumping Range

The pumping range of the pump is determined by the float

switch tether cord. Use Table 7 as guide line to determine

your required pumping range. Pumping ranges are based

on non-turbulent conditions. Range may vary due to water

temperature and cord shape. Please note as the tether

length increases, so does the variance of the pumping

range.

Design Features

Float switch housings are constructed of high-impact,

corrosion resistant polypropylene with mechanically

activated, snap action contacts.

Suitable for most liquid environments.

Hermetically sealed.

Thick-walled non-corrosive PVC plastic enclosure.

Pressure tested to 30 ft. (9 meters).

Standard SJO, 16-gauge, 2 conductor cord (20 ft./6.09 m).

Figure 12. Float Switch (Closed)

Figure 13. Float Switch (Open)

ON/OFF

RAMP

STEEL

BALL

CONTACTS

CLOSED

ON/OFF

RAMP

STEEL

BALL

CONTACTS

OPEN