Maintenance (pump), Testing the venturi nozzle, Checking operation of float assembly – Multiquip AP6 Series User Manual

Page 50

PAGE 50 — AP6/AP8 SERIES TRASH PUMPS • OPERATION AND PARTS MANUAL — REV. #0 (06/11/14)

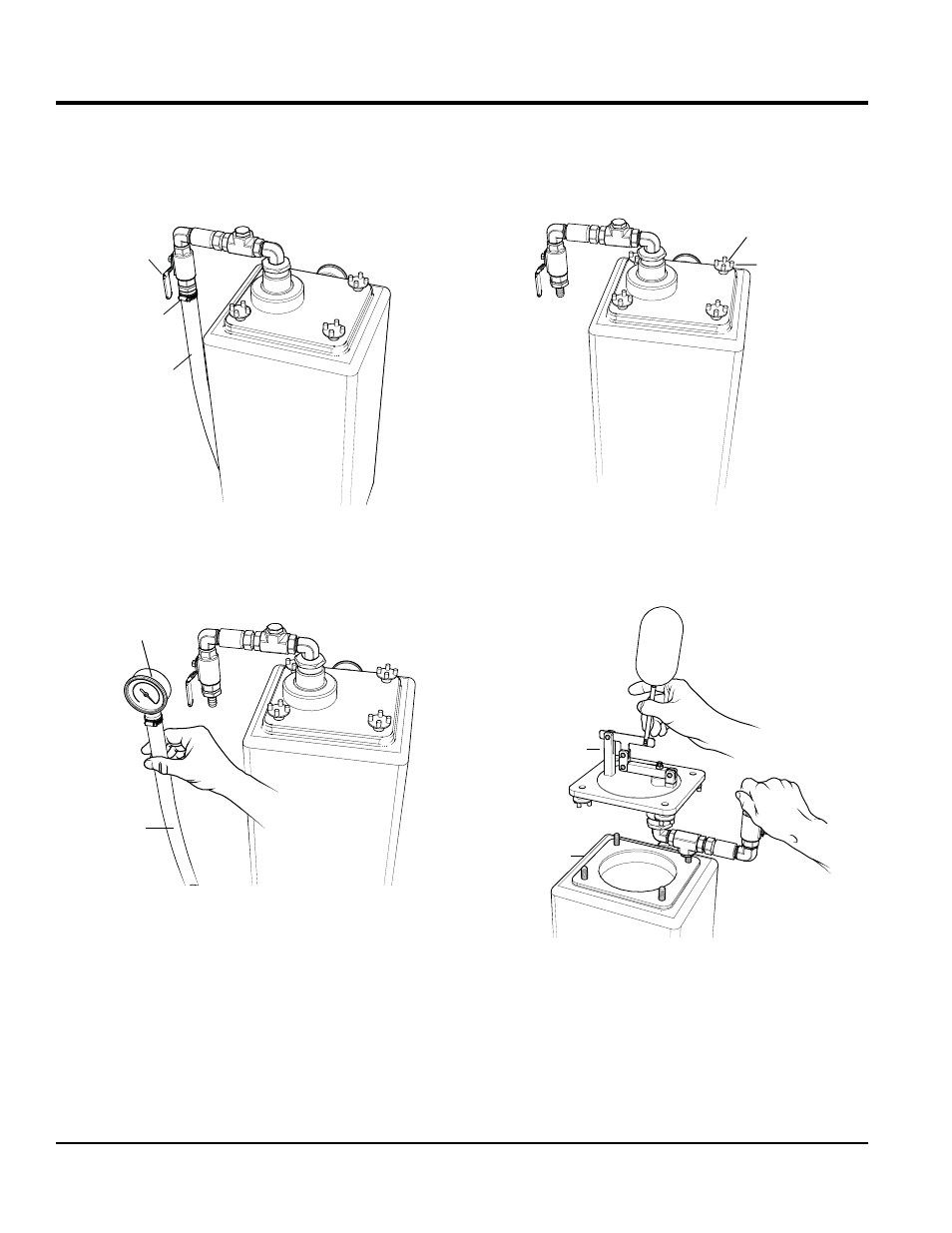

Testing the Venturi Nozzle

1. Using a flat blade screw driver, disconnect the hose

(Figure 42) connected to the suction chamber ball

valve.

Figure 42. Venturi Hose Disconnection

2. Attach a 0 to 30 inch vacuum gauge to the free end of

the venturi hose as shown in Figure 43.

Figure 43. Vacuum Gauge

3. Start the engine. The test gauge should read 25 in. Hg.

4. If the vacuum reads 25 in. Hg or higher, then it can be

assumed the pump is working correctly.

5. Stop the engine. Remove the gauge, and reconnect the

venturi hose to the suction chamber ball valve.

SUCTIO

N

CHAMBER

BALL

VALVE

HOSE

CLAMP

VENTURI

HOSE

VACUUM

GUAGE

SUCTIO

N

CHAMBER

VENTURI

HOSE

MAINTENANCE (PUMP)

Checking Operation of Float Assembly

1. Remove the 4 wrench nuts (Figure 44) from the top of

the suction chamber.

Figure 44. Wrench Nut Removal

2. Carefully remove the float assembly, and place it on

top of the suction chamber, as shown in Figure 45.

Figure 45. Float Assembly Removal

SUCTIO

N

CHAMBER

WRENCH

NUTS (4)

REMOVE

SUCTIO

N

CHAMBER

FLOAT

ASSEMBLY

TOP