Maintenance (engine) – Multiquip AP6 Series User Manual

Page 54

PAGE 54 — AP6/AP8 SERIES TRASH PUMPS • OPERATION AND PARTS MANUAL — REV. #0 (06/11/14)

8. Fill engine crankcase with high quality detergent oil

classified. Fill to the upper limit of dipstick.

DO NOT

overfill. Reference Table 3 for crankcase oil capacity.

9. Run the engine briefly for several minutes. Watch for

oil leakage. Shut the engine down and allow it to sit

for several minutes. Top off the oil to the upper limit on

the dipstick.

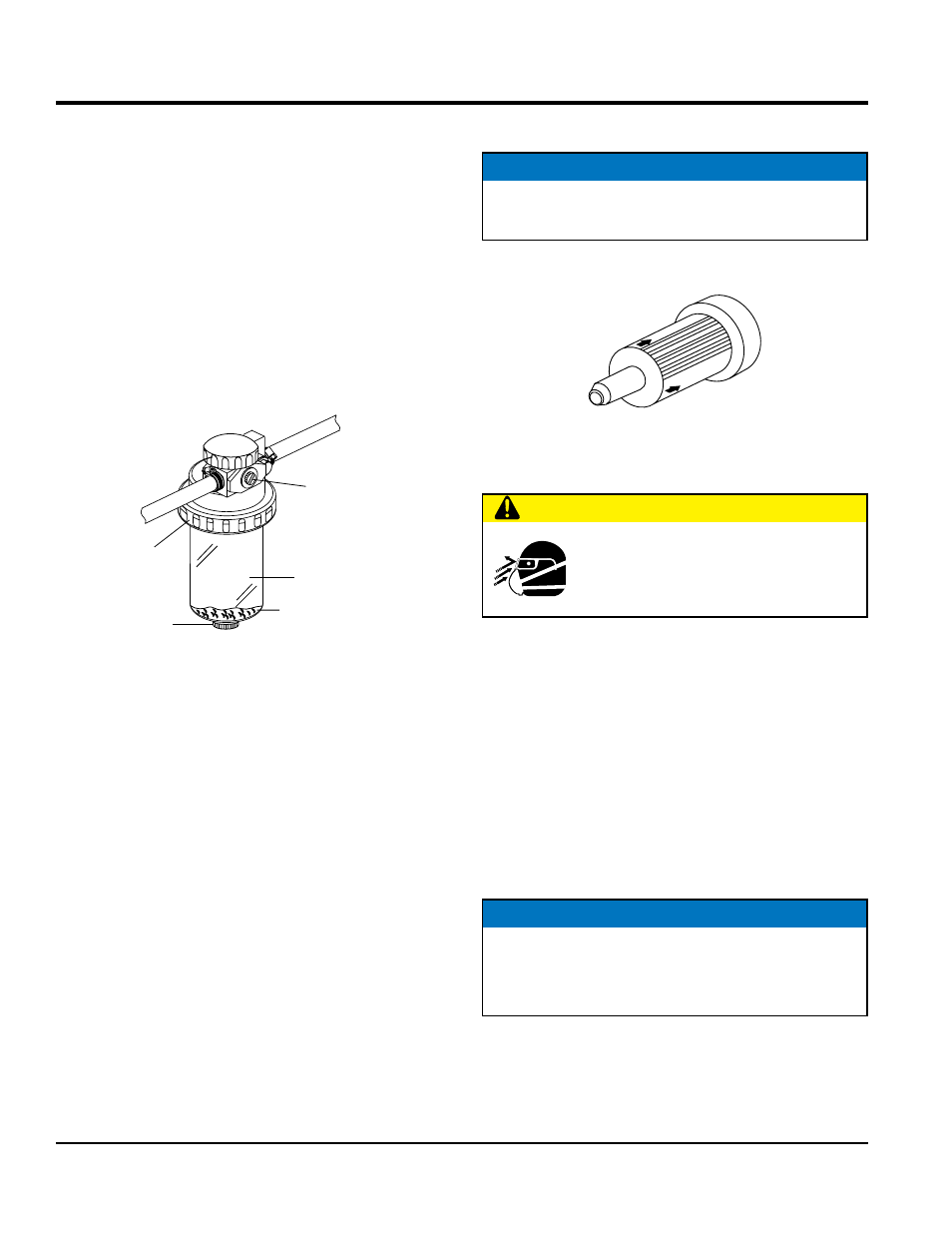

Fuel Water Separator Bowl

1. Inspect fuel water separator bowl (Figure 48) daily. If

the bowl has collected a significant amount of water

and sediment at the bottom of the bowl, it should be

drained off.

Figure 48. Fuel Water Separator

2. Loosen drain plug at bottom of bowl.

3. Loosen air bleed plug two full turns and drain water

from bottom until fuel starts to drain out.

4. When fuel starts to drain out, tighten drain plugs

securely.

5. After draining water from the fuel water separator, the

fuel system must be primed by bleeding air from the

fuel system. Referer to your John Deere Operator's

Manual, "Bleeding Fuel System".

AIR BLEED

PLUG

RETAINING

RING

BOWL/CUP

WATER/SEDIMENT

DRAIN PLUG

MAINTENANCE (ENGINE)

In-Line Fuel Filter

Replace the engine in-line fuel filter (Figure 49) every year or

300 hours.

Figure 49. In-Line Fuel Filter

Air Filter (250 Hours)

Air Cleaner

1. Release the latches (AP6 only) located on either side

of the air cleaner dust pan. Remove the dust pan and

both the primary and secondary air filters

2. Turn the air filter cover release knob (AP8 only)

counterclockwise and remove air cleaner cover.

Remove the wing nut and primary air filter element

3. Check the air cleaner daily or before starting the engine

4. Check for and correct heavy buildup of dirt and debris

along with loose or damaged components.

NOTICE

When reinstalling fuel filters, please note the arrows

indicating the direction of fuel flow.

CAUTION

Wear protective equipment such as

approved safety glasses or face shields

and dust masks or respirators when

cleaning air filters with compressed air.

NOTICE

Operating the engine with loose or damaged air cleaner

components could allow unfiltered air into the engine

causing premature wear and failure.