Trailer safety guidelines, Wheel rims, Wheels, bearings and lug nuts – Multiquip AP6 Series User Manual

Page 74: Lug nut torque requirements

PAGE 74 — AP6/AP8 SERIES TRASH PUMPS • OPERATION AND PARTS MANUAL — REV. #0 (06/11/14)

TRAILER SAFETY GUIDELINES

Table B below will help pinpoint the causes and solutions

of tire wear problems.

Wheel Rims

If the trailer has been struck, or impacted, on or near the

wheels, or if the trailer has struck a curb, inspect the rims for

damage (i.e. being out of round); and replace any damaged

wheel. Inspect the wheels for damage every year, even if

no obvious impact has occurred.

Wheels, Bearings and Lug Nuts

A loose, worn or damaged wheel bearing is the most

common cause of brakes that grab.

To check wheel bearings, jack trailer and check wheels

for side-to-side looseness. If the wheels are loose, or spin

with a wobble, the bearings must be serviced or replaced.

Check infl ation pressure weekly during use to insure the

maximum tire life and tread wear. Most trailer axles are

built with sealed bearings that are not serviceable. Sealed

bearings must be replaced as complete units.

Table B. Tire Wear Troubleshooting

Wear Pattern

Cause

Solution

Center Wear Over infl ation.

Adjust pressure to particular

load per tire manufacturer.

Edge Wear

Under infl ation.

Adjust pressure to particular

load per tire manufacturer.

Side Wear

Loss of camber

or overloading.

Make sure load does not

exceed axle rating.

Align wheels.

Toe Wear

Incorrect toe-in.

Align wheels.

Cupping

Out-of-balance.

Check bearing adjustment

and balance tires.

Flat Spots

Wheel lockup and

tire skidding.

Avoid sudden stops when

possible and adjust brakes.

WARNING

ALWAYS wear safety glasses when

removing or installing force fi tted parts.

DO

NOT attempt to repair or modify a wheel.

DO NOT install an inner-tube to correct a

leak through through the rim. If the rim is

cracked, the air pressure in the inner tube may cause

pieces of the rim to explode (break off) with great force

and cause serious eye or bodily injury.

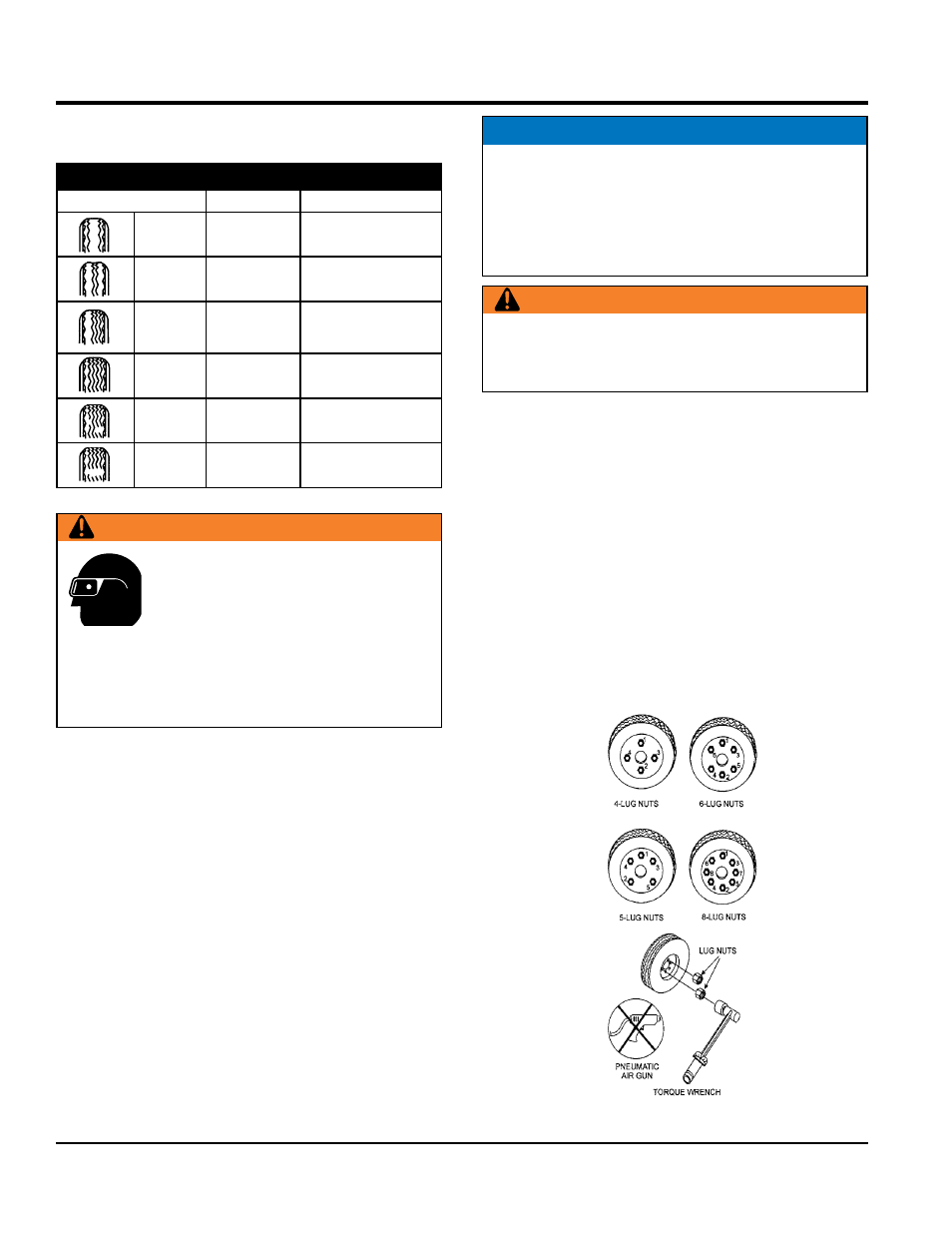

Lug Nut Torque Requirements

It is extremely important to apply and maintain proper wheel

mounting torque on the trailer. Be sure to use only the

fasteners matched to the cone angle of the wheel. Proper

procedure for attachment of the wheels is as follows:

1. Start all wheel lug nuts by hand.

2. Torque all lug nuts in sequence. See Figure L. DO

NOT torque the wheel lug nuts all the way down.

Tighten each lug nut in 3 separate passes as defi ned

by Table C.

3. Check to see if the lug nuts are tight after the fi rst 10,

25 and 50 miles of driving and before each tow

thereafter

Figure L. Wheel Lug Nuts Tightening Sequence

WARNING

Lug nuts are prone to loosen after initial installation,

which can lead to death or serious injury. Check all

wheel lug nuts periodically.

NOTICE

NEVER use an pneumatic air gun to tighten wheel

lug nuts.

Over-tightening lug nuts will result in breaking the studs

or permanently deforming the mounting stud holes in

the wheels.