Inspection/setup – Multiquip AP6 Series User Manual

Page 30

PAGE 30 — AP6/AP8 SERIES TRASH PUMPS • OPERATION AND PARTS MANUAL — REV. #0 (06/11/14)

INSPECTION/SETUP

FUEL CHECK

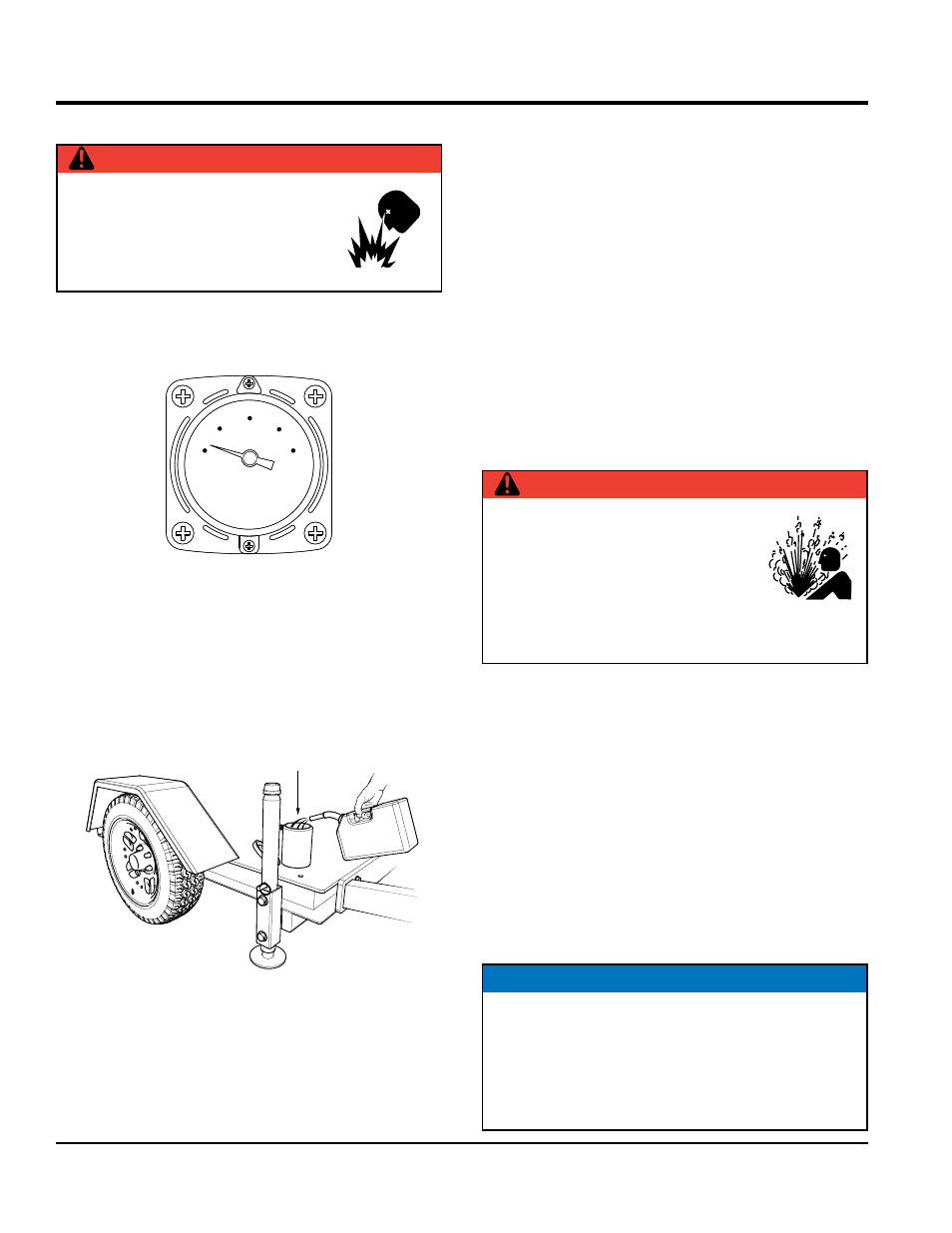

1. The fuel tank used with this pump has a built in fuel

gauge (Figure 19) within the tank. Read the fuel gauge

to determine if the fuel level is low.

Figure 19. Fuel Gauge

2. Handle fuel in a safety container. If the container does

not have a spout use a funnel.

3. If the fuel level is low, fill (Figure 20) with recommended

type diesel fuel as referenced in Table 3.

DO NOT fill

fuel tank beyond capacity.

Figure 20. Refueling

4. Pay attention to the fuel tank capacity when replenishing

fuel. Refer to the fuel tank capacity listed in Table 4,

Trailer Specifications.

5. Tighten fuel tank cap securely after filling.

DANGER - Fire/Explosion

NEVER fill the fuel tank while the engine

is running or in the dark. Fuel spillage on

a hot engine can cause a fire or explosion.

If fuel spillage occurs, wipe up the spilled

fuel completely to prevent fire hazards.

E

1/2

F

DIESEL FUEL

FUEL FILLER

PORT

BATTERY CABLE CONNECTION

ALWAYS make sure the battery cables are properly

connected to the battery terminals. The

RED cable is

connected to the positive terminal of the battery, and the

BLACK cable is connected to the negative terminal.

PUMP PLACEMENT

1. Read safety instructions at the beginning of manual.

2. Place pump on secure level ground as near to the

water as possible.

3. Deploy all four trailer jack stands to level the pump. If

possible place chock blocks underneath each wheel

to prevent the pump from rolling.

SUCTION/DISCHARGE HOSES CONNECTIONS

1. Check that the suction and discharge hoses (Figure 21)

are securely attached to the pump via Bauer™couplers

and are not restricted.

2. Place each hose so that it lays as straight as it is

possible on the ground. Remove any twists or sharp

bends from hose which may block the flow of water.

3. If using a light weight discharge hose, it should be

anchored to avoid movement with high flow or high

pressure water. Always use a suction hose or pipe that

matches the size of the pump inlet to insure optimum

performance and reduce the risk of damage to the

pump.

DANGER -High Pressure

PVC discharge hoses and thin-walled

rubber hoses can easily fail at the end

of the hose fittings. Leaks from the

hoses can cause high-pressure liquid

to be discharged, causing dangerous

conditions. Make sure pressure rating of hoses exceeds

the pump maximum pressure to prevent hose failure.

NOTICE

If.t is recommended that the discharge hose or pipe

match the size of the pump outlet to reduce friction as

much as possible. Using a discharge line that is larger

than the pump outlet will reduce friction and improve

water flow. Similarly, a smaller line will reduce water

flow by increasing friction.