Maintenance (engine), Engine maintenance – Multiquip AP6 Series User Manual

Page 52

PAGE 52 — AP6/AP8 SERIES TRASH PUMPS • OPERATION AND PARTS MANUAL — REV. #0 (06/11/14)

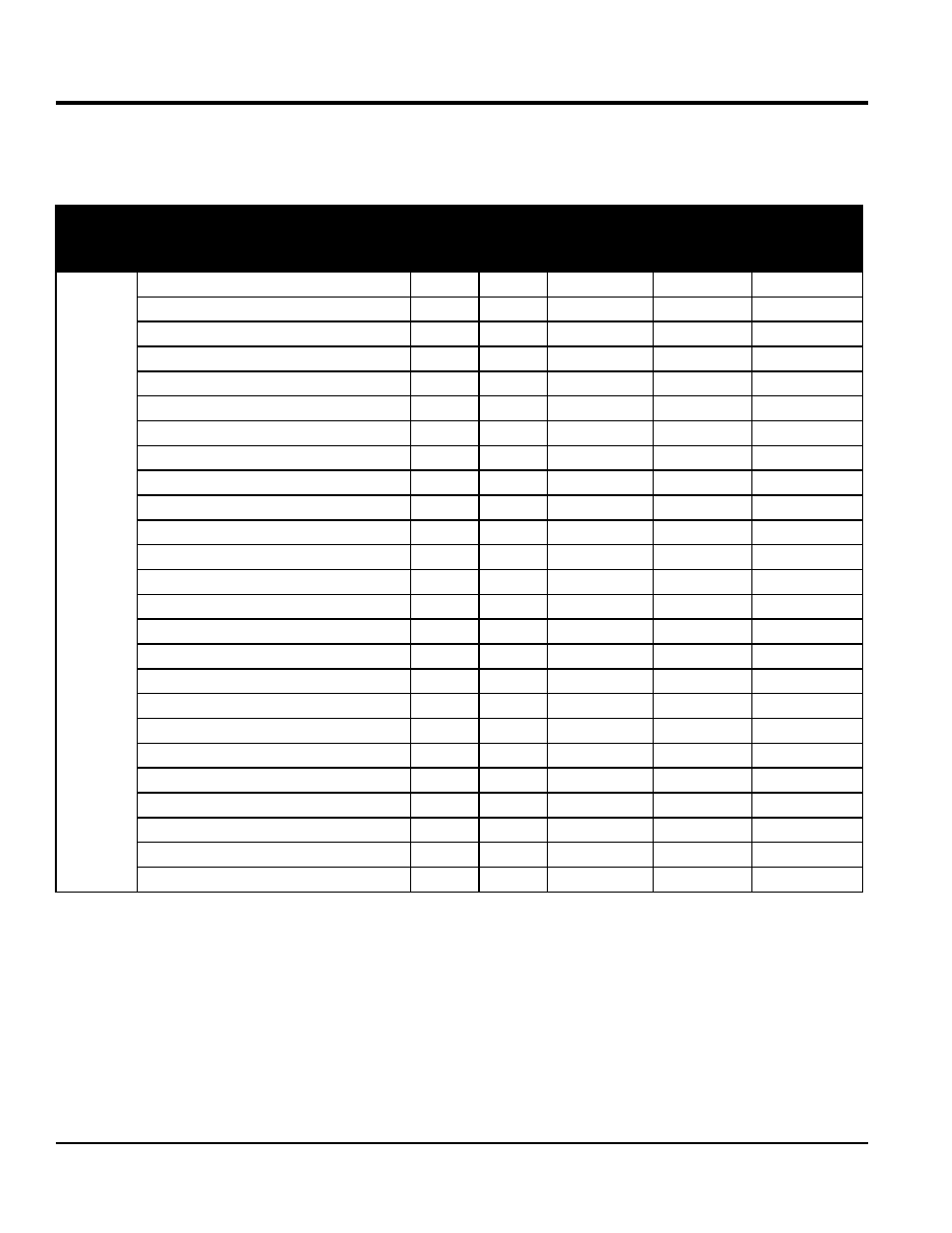

MAINTENANCE (ENGINE)

Table 17. Inspection/Maintenance

10 Hrs

DAILY

250 Hrs

500 Hrs

or Every

12 Months

3000 Hrs

or Every

36 Months

OTHER

Engine

Check Engine Oil and Coolant Levels

X

Check Fuel Filter/Water Separator Bowl

X

Check Air Cleaner

X

Check Air Cleaner Element

X

Check for Leaks/Hoses/Clamps

X

Check for Loosening of Parts

X

Change Engine Oil and Oil Filter *

1

X

Clean Unit, Inside and Outside

X

Replace Fuel Filter Elements

X

Check Engine Mounts

X

Service Battery

X

Check Air Intake Hoses

X

Check Fan Belt Condition

X

Check Automatic Belt Tensioner

X

Check Electrical Ground Connection

X

Clean Radiator, Check Cooling System

X

Coolant Solution Analysis, Add SCA's As Required

X

Pressure Test Cooling System

X

Check Engine Speed

X

Test Thermostats

X

Check and Adjust Engine Valve Clearance

X

Test Glow Plugs

X

Flush and Refill Cooling System*

2

2 yrs. or 2000 hrs.

Clean Inside of Fuel Tank

1000 hrs.

Replace Air Cleaner Elements *

3

As Required

ENGINE MAINTENANCE

The following engine maintenance guidelines are intended to assist the operator in preventative maintenance. For a more

detailed maintenance schedule refer to the

John Deere Engine Operator's Manual supplied with the pump.

*

1

During initial operation of a new engine, change oil and filter between a minimum of 100 hrs. and a maximum of 250 hrs. Service interval depends

on type of oil.

*

2

If John Deere COOL-GARD™ John Deere COOL-GARD™ II is used, the flushing intervals may be extended. See "Testing Diesel Coolant" in

engine manual.

*

3

Replace primary air filter element when restriction indicator shows a vacuum of 625 mm (25 in. H

2

0).