Error codes – Heidolph Automatic Module Distimatic User Manual

Page 45

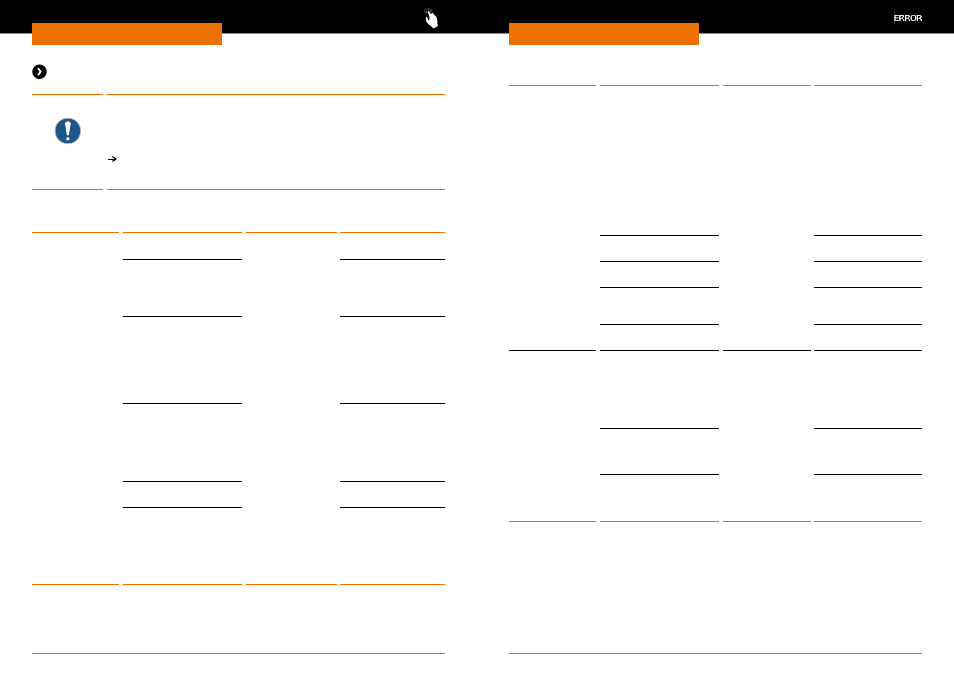

Error Codes

89

88

Error Codes

Error code

Cause

Consequence

Measure

Error 1:

Cut-out sensor

a. Cut-out sensor

not connected.

The cut-out

sensor triggers

safe shutdown

and initiates the

final process (in

the event of an

error). The error

code appears.

a. Connect the

cut-out sensor.

b. Cut-out sensor not

placed correctly.

b. Place the

cut-out sensor

as described

in the chapter

„Installation”.

c. The cut-out sensor

is responding too

sensitively to small

drops that are

falling down within

the condenser

on the wall.

c. Set the cut-out

sensor to be

less sensitive

(see chapter

„Operation” –

„Adjusting the

sensitivity of

the sensors”).

d. The condensate has

accumulated in the

condenser and

can no longer be

discharged. Valve

at the valve matrix

is clogged.

d. Clean the

valves at the

valve matrix.

e. Cable break in the

cut-out sensor.

e. Contact Technical

Service.

f. The condensate has

accumulated in the

condenser and

can no longer

be discharged.

The valve matrix

is defective.

f. Contact Technical

Service.

Error code

Cause

Consequence

Measure

Error 2:

Unable to

drain collector

The condensate in the

collector vessel can no

longer be discharged.

a. The level sensor

at the collector is

not responding

to a dip in the fill

level possibly since

there are drops of

condensate in the

collector or the

sensor adjustment

is such that it is

too sensitive.

The level sensor

at the collector

triggers safe

shutdown and

initiates the

final process (in

the event of an

error). The error

code appears.

a. Set the level

sensor on the

collector to be

less sensitive

(see chapter

„Operation” –

„Adjusting the

sensitivity of

the sensors”).

b. The PTFE tube at the

collector is clogged.

b. Clean the

PTFE tube.

c. The condensate

pump is dirty.

c. Clean the

condensate pump.

d. Cable break in

the level sensor

at the collector.

d. Contact Technical

Service.

e. The condensate

pump is defective.

e. Contact Technical

Service.

Error 3:

Collection

vessel

a. Overflow sensor

for condensate

and residue vessel

is not connected

(only on Distimatic

including automatic

drainage of residue).

The overflow

sensor for

condensate

and residue

vessel (only

on Distimatic

including

automatic

drainage of

residue) triggers

safe shutdown

and initiates the

final process (in

the event of an

error). The error

code appears.

a. Connect the level

sensor at the

condensate or

residue vessel.

b. The condensate

vessel or residue

vessel is full.

b. Drain the

condensate

vessel or residue

vessel.

c. Cable break in the

overflow sensor for

condensate and

residue vessel.

c. Contact Technical

Service.

Error codes

Date and time

Since error codes are automatically stamped with date and time, we

recommend you to keep the date up to date in order to facilitate error

analysis.

Regularly check whether date and time are up to date (see chapter

„Operation” – „Set parameters” – „Setting date and time”).