Red Lion MDC User Manual

Page 48

-46-

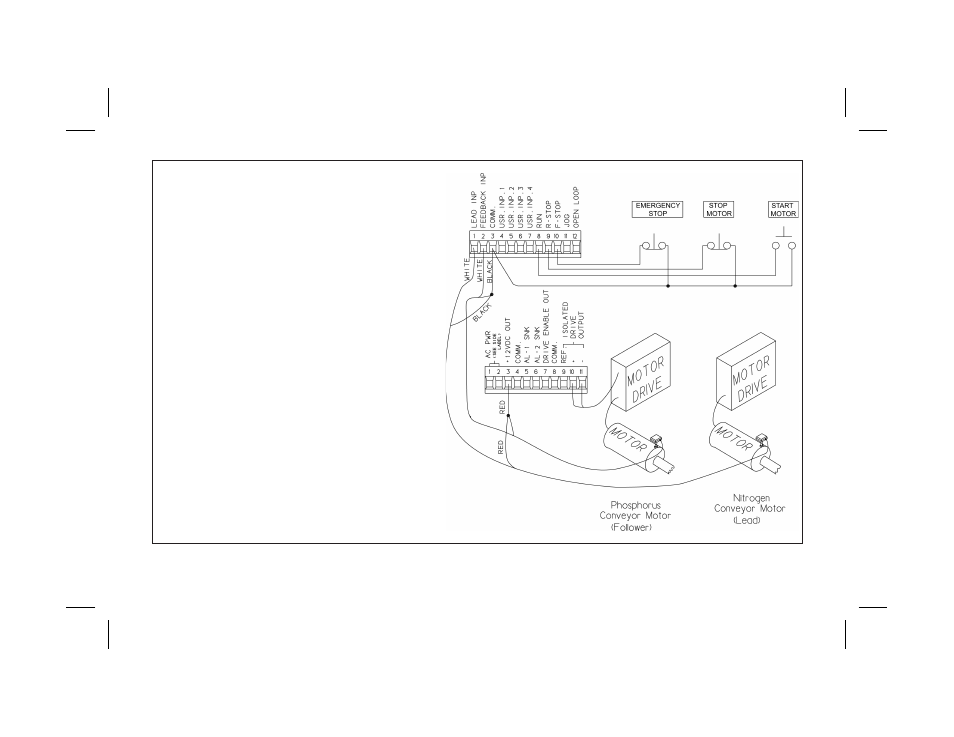

FOLLOWER MODE APPLICATION

A fertilizer production facility is mixing pellets containing

Nitrogen with pellets that contain Phosphorus. A chemical ratio of

1:1 is determined by the speed of two different conveyors. Because

of differences in the gearing of the conveyor and concentration of

the pellets, the Nitrogen conveyor motor must run at 3 times the

speed of the Phosphorus conveyor motor in order to produce a 1:1

mix. The maximum speed of both motors is 2000 RPM. Set the

follower MDC scaling to produce a 1:1 mix of Nitrogen and

Phosphorus when a setpoint of 1.0000 is entered. Display speed

units are in RPM’s. Both the lead and feedback frequency are taken

from 60 tooth gears on each motor shaft.

1) Choose the Phosphorus conveyor motor for the follower MDC.

It runs slower than the Nitrogen conveyor motor.

2) Set the Pulses per revolution feedback to 60.

3) Set the MAX RPM feedback to 2000. This is the conveyor

motor’s maximum operating speed.

4) Set display decimal point to 0.

5) Set display unit to 2000. The display speed unit maximum is

2000 at a MAX RPM FB of 2000. If the display units wanted

were conveyor feet/minute or Phosphorus pellets in lbs/sec, the

equivalent display value for 2000 RPM would be entered.

6) Set the pulses per revolution lead to 60.

7) Setting the MAX RPM Lead:

This is the Lead RPM that would be necessary to have a 1:1

mixture if the Follower Speed was MAX RPM FB (2000 RPM).

Since the Nitrogen conveyor motor must run 3 times as fast as the

Phosphorus motor, MAX RPM LD = 3 x 2000 = 6000 RPM. Set

MAX RPM LD = 6000 RPM. This is the correct value, even though

the Nitrogen conveyor motor would never actually run at 6000

RPM. A ratio setpoint of 1.0000 on the MDC is now equal to a 1:1

mixture of Phosphorus and Nitrogen.