Red Lion MDC User Manual

Page 36

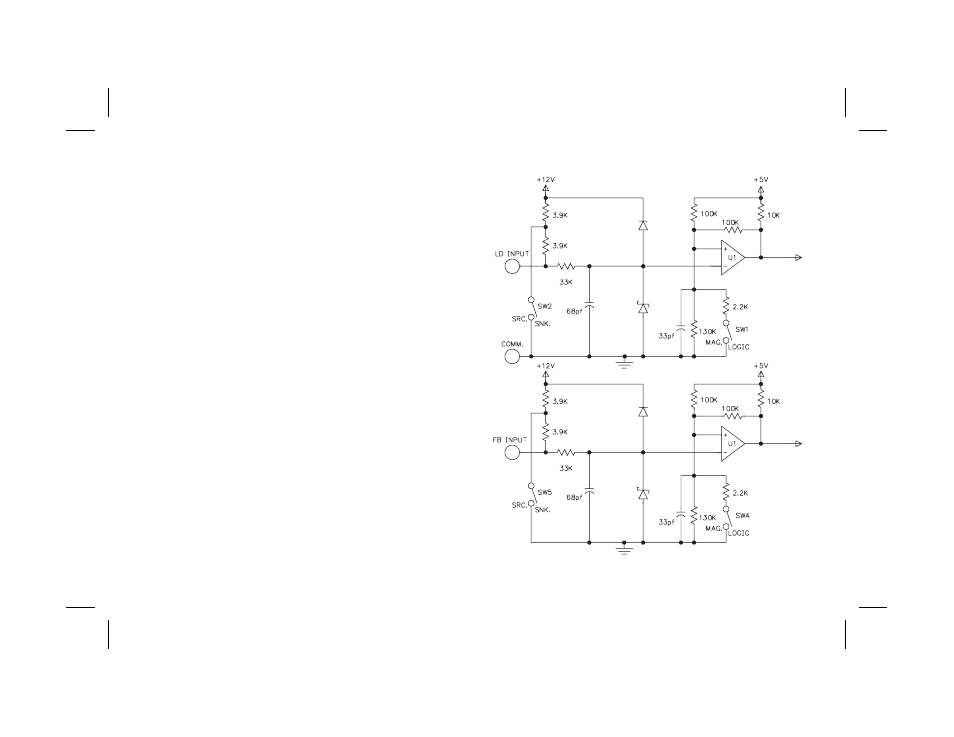

SIGNAL WIRING

LEAD AND FEEDBACK FREQUENCY INPUTS

The Lead and Feedback Inputs have identical input circuitry. The Lead and

Feedback inputs each have separate DIP switches for setting the type of signal

input. A Magnetic Pickup or Logic Input signal can be sent to either input. When

a MAGNETIC PICKUP is used, the Sink/Source DIP switch, for the appropriate

input, must be in the “SRC” position for the frequency to be detected.

The Input schematic shows the details of the Lead and Feedback input

circuitry. Both inputs share the same common. Each input has two DIP

switches associated with it. The functions of these switches are as follows:

LEAD INPUT

SW1 - MAG: Sets input for a Magnetic Pickup signal.

Sensitivity: 200 mV peak;

Hysteresis: 100 mV

LOGIC: Sets input for a Logic signal.

Input trigger levels: V

IL

= 1.5 V max; V

IH

= 3.75 V min.

Note: SW2 Must be in the “SRC” position for a Magnetic Pickup signal.

SW2 - SNK: Provides a 7.8 KW internal pull-up resistor for sensors with

current sinking outputs.

SRC: Provides a 3.9 KW internal pull-down resistor for sensors

with current sourcing outputs.

FEEDBACK INPUT

SW3 - Same as SW1

SW4 - Same as SW2

Note: SW4 must be in the “SRC” position for a Magnetic Pickup signal.

Note: A Magnetic Pickup type sensor should not be used unless a large enough

signal is provided at all speeds of operation.

-34-