4 adjusting the roughness factor, Ctor – paragraph 3.5.4, Operating procedures – Dwyer Series PUF User Manual

Page 26

3: Operating Procedures

22

3.5.4 Adjusting the roughness factor

The roughness factor compensates for the condition of the internal pipe wall, as a rough surface will cause

turbulence and affects the flow profile of the liquid. In most situations it is not possible to inspect the pipe

internally and the true condition is not known. In these circumstances experience has shown that the following

values can be used:

4.

Press the

Options key to access the FLOW

READING OPTION screen shown.

5.

Scroll down and select

Calibration factor.

6.

Change the calibration factor according to the

error calculated in step 3. For example, if the

PUF was reading 1% high then increase the

Calibration factor value by 0.010.

Conversely, if the reading is 1% low then

decrease the calibration factor to 0.990.

7.

Press the

Enter key to apply the change.

8.

Select

Roughness factor or Exit as

required.

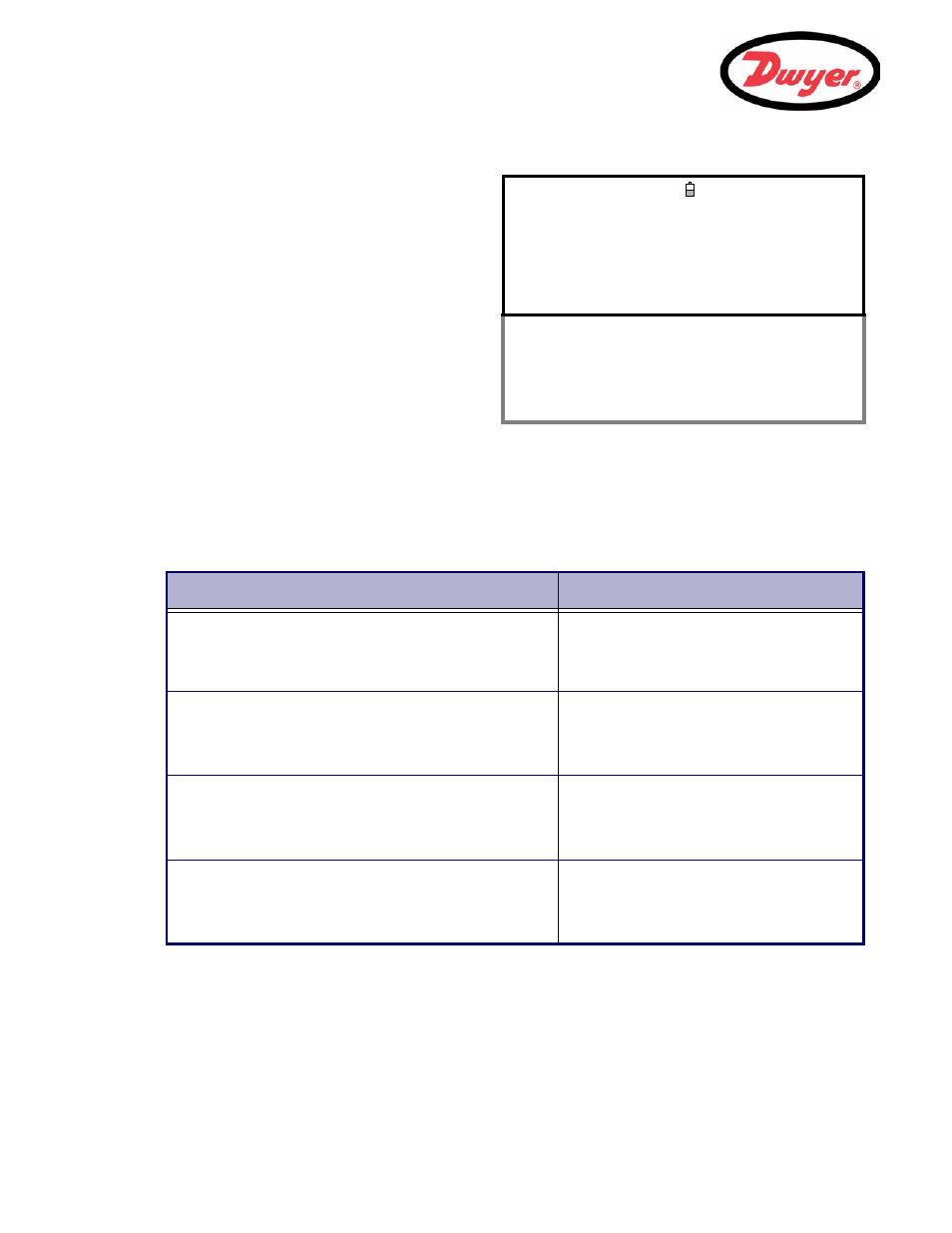

FLOW READING OPTION

DD-MM-YY HH:MM:SS

Data review

Zero Cutoff (m/s) : 0.00

Set zero flow (m/s) : 0.00

Damping (secs) : 10

Totalizer : Run

Reset +Total

Reset –Total

Calibration factor : 1.000

Roughness factor : 0.01

Diagnostics

Select Totals : Both

Exit

Pipe Material

Roughness Factor

Non ferrous metal

Glass

Plastics

Light metal

0.01

Drawn steel pipes:

• Fine planed, polished surface

• Plane surface

• Rough planed surface

0.01

Welded steel pipes, new:

• Long usage, cleaned

• Lightly and evenly rusted

• Heavily encrusted

0.1

Cast iron pipes:

• Bitumen lining

• New, without lining

• Rusted / Encrusted

1.0