5 natural ventilation – Hired-Hand Evolution Series 1200 User Manual

Page 27

Part No. 4801-5331 Rev 2-08

Evolution 1200

27 of 64

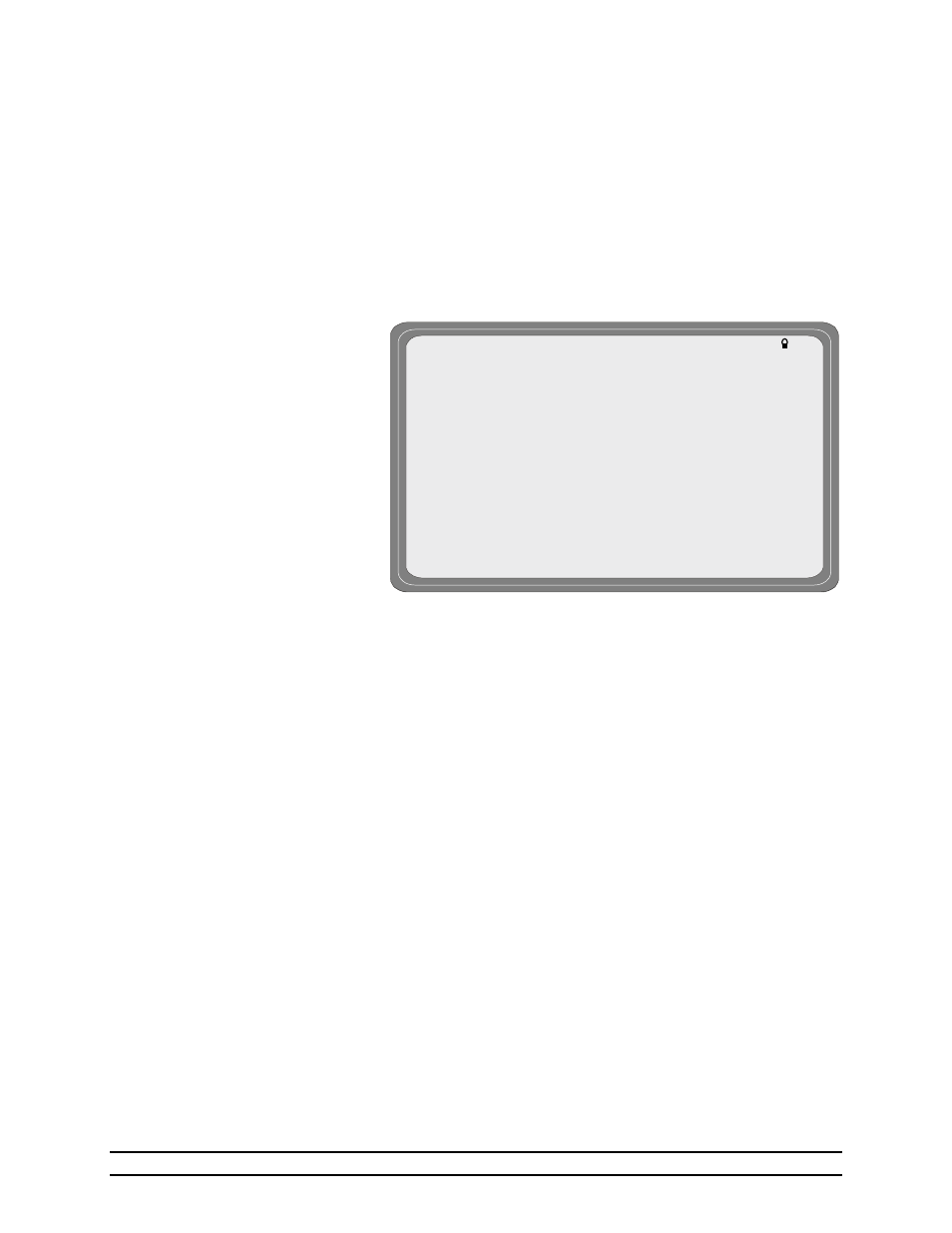

**(1)NATURAL VENTILATION**(Target:70.0°)

"

(2)Allow Natural Ventilation = No

(3)

(4)

(5)

Current

Cool

Warm

(6)Temp Diff (In-Out):

( 15° )

30°

5°

(7)Cycle Time

( 2 m )

2 m

3 m

(8)Initial Drop Delay:

(2 cyc)

3 cyc

0cyc

(9)Initial Run Time:

( 42 s)

30 s

60 s

(10)Open Runtime:

( 18 s)

10 s

35 s

(11)Close Runtime:

( 37 s)

41 s

38 s

(12)Aggr Range (+/-):

( 2.6°)

2.0°

5.0°

(13)# (14)SENSORS (15)MODE (16)OPEN (17)CLOSE

U1 --654321 NAT 77.5° 75.0°

U2 --654321 N&T 76.5° 74.0°

(5) Reaction Delay – The amount of time delay before the vent machine operates.

(6) Pressure Differential - Number from target to start opening and closing vents.

Example: With Target 0.07 and Differential 0.02, the vents open when the pressure is above 0.08; The

vents will close when the pressure is below 0.06.

(7) Pressure Ramping – Select On or Off to enable or disable pressure ramping.

(8 & 9) Target Press. @ High Temp - The target pressure when the outside temperature is at the high

temperature limit. Set both pressure and temperature limit.

(10 & 11) Target Press. @ Low Temp -The target pressure when the outside temperature is at the low

temperature limit. Set both pressure & temperature limit.

7.5 Natural

Ventilation

Natural Ventilation options are:

(1) Target Temperature –

Displays the existing

Target Temperature.

(2) Allow Natural Ventilation

– Yes or No. This must

be set to yes before the

control is allowed to

enter into natural

ventilation.

(3) Current – This is the value

currently being used

derived from the cool

and warm settings.

(4) Cool – The desired

operational settings for a cooler outside temperature.

(5) Warm – The desired operational settings for warm outside conditions which would be very near the

target temperature.

(6) Temp Diff (In-Out) – The Temperature Differential which is the inside target minus the outside

temperature.

(3) Cycle Time – The length of time in minutes between the start of one curtain position adjustment, and

the start of the next curtain position adjustment. ( A Cycle time of 3 means that the curtain will

move up or down, or remain stationary, depending upon temperature for its runtime once every 3

minutes).

(8) Initial Drop Delay – The number of cycles that the curtain will be delayed after the Initial Drop.

(5) Initial Run Time – When the controller determines that the curtains should run open and senses that

they are closed, it uses this parameter for the 'first' run. This setting is used to allow the curtains

to open enough on the first run to guarantee adequate ventilation. Valid settings are 1 to 240

seconds.

(10) Open Run Time – Period of time the curtain will run open each cycle.

(11) Close Run Time – Period of time the curtain will run close each cycle.

(6) Aggressive Range – If this Temperature limit is exceeded, the run times of the stages are doubled.

NOTE: If the temperature is at the open setting, the control will run the machine for the runtime

you have set. As the temperature moves up, your runtime will also increase. The runtime may

ramp up to two times the selected Run Time depending on the amount of temperature difference

past the Open or Closed set temperatures. As the temperature gets closer to the Aggressive Range

tolerance, the Run Time gets closer to the maximum two times Run Time. Your runtime will have

doubled once the temperature reaches the set Aggressive Range/tolerance. This is also true for the

close side of the curtain machine.

(7) Unit #2 is Tunnel Inlet –Yes or No. -YES sets U2 to OPEN during Tunnel. The tunnel machine will

use the same settings that unit 1 does for natural ventilation.

Example: If you have natural unit #1 as the main curtain and natural #2 as the tunnel curtain.

Natural unit #1 and natural #2 will operate at the same time together. They will both use the

settings for Unit #1.

(8) # - Identify either Unit #1 or Unit #2.