Hired-Hand Evolution Series 1200 User Manual

Page 23

Part No. 4801-5331 Rev 2-08

Evolution 1200

23 of 64

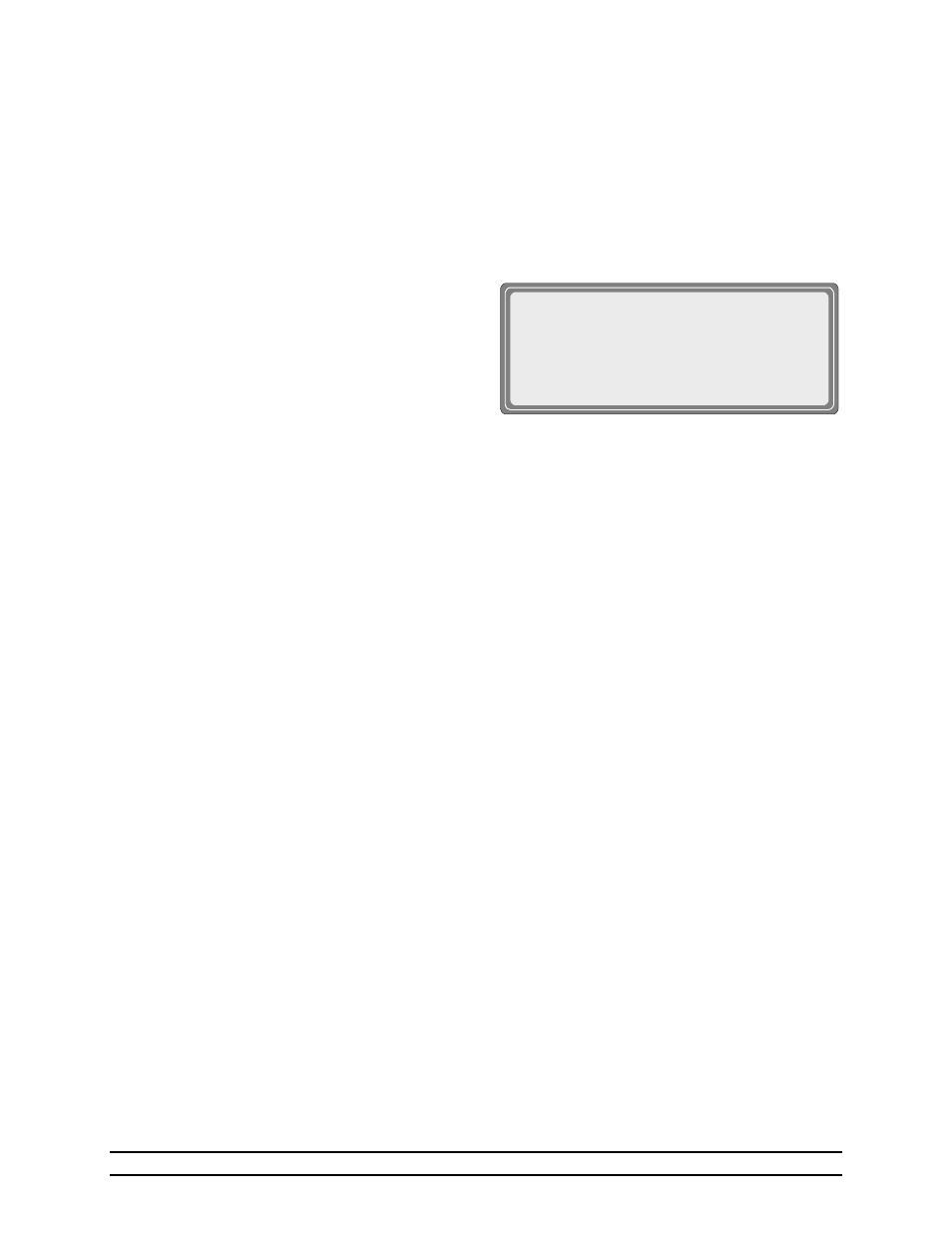

(1)Tunnel Alarm Details

(2)Alarm On/Off = Off

(3)Last Alarm Statistics:

(4)Date: 02/06 (4)Time: 1:09a

(5)Cause: Nat Auxiliary

(6) Cause - Displays the reading of the low temperature that caused the alarm.

Possible Reasons for Low Temperature False Alarm Conditions:

• If the same sensor causes multiple alarms, check the location of the sensor and wiring for possible

damage. Also insure that the limit is properly set for the target and room temperature.

6.7.3 Tunnel Vent Alarm Details

The Tunnel Alarm Details shows the settings for the alarm, the last time the alarm was sounded and the

cause of the alarm.

(1) Tunnel Alarm Details – Identifies the

following information:

(2) Alarm On/Off – The status of the alarm is On

or Off due to tunnel. Not settable. Status

indicator only. NOTE: This alarm is

automatically set by the Evolution 1200

Controller.

(3) Last Alarm Statistics - Identifies the date, time and cause of the last alarm.

(4) Date & Time - The date and time of the last alarm.

(5) Cause - Displays the cause of the tunnel error. The following are the problems that could cause a

Tunnel Error:

Tunnel Auxiliary would be when the controller has seen a closed signal from the tunnel curtain

during tunnel. After 20 seconds the system will come out of tunnel and return to natural or

power ventilation.

Nat Auxiliary would be when the controller has seen an open signal from the natural curtains

during tunnel or that the curtains never closed from natural allowing the system to go into

tunnel. This alarm would take 13 minutes from when it started to go into tunnel. After 20

seconds the system will come out of tunnel and return to natural or power ventilation.

Low Pressure would be when the pressure fell below the low pressure alarm setting during tunnel.

This alarm will need to see the pressure below the limit for 45 seconds. At this point the Alarm

Status LED will start blinking. Then after another 20 seconds the system will come out of

tunnel and return to natural or power ventilation.

High Pressure would be when the pressure went above the high limit alarm setting during tunnel.

This alarm will need to see the limit exceeded for 45 seconds. At this point the Alarm Status

LED will start blinking. Then after another 20 seconds the system will come out of tunnel and

return to natural or power ventilation.

Possible Reasons for Tunnel Vent Alarm Conditions:

• Tunnel Inlet failed to open.

• Natural Curtain failed to close.

• High Static Pressure due to lack of inlet opening.

NOTE: Due to the nature of these errors, the control tunnel enable must be reset in order for the

control to re-enter tunnel. Be sure to check the cause if this is a reoccurring problem.