Davey Speedman Dual Pump Variable Speed Pump Control System User Manual

Page 59

59

Pump shutting down on

Pump Protection

•

Fault in protection sensor

•

Replace or adjust sensor

Controller powers on and

off continuously

•

Voltage being applied to the

Inputs.

•

Excessive current being

drawn from the external

pressure sensor

•

Make sure that the Inputs are Voltage

Free

•

Check external sensor current 100mA

max.

Can’t tune the set point

above/Below a number

•

The set point must be

between the Cut In pressure

and the High Pressure limit

•

Adjust HP limit or Cut In pressure to allow

the Set point to move

•

Check Set Point 2 & 3 to make sure that

they are not above HP Limit or below Cut

In pressures

System Displays wont

initialise

Loading Data message

cycles continuously

•

System needs to be

initialised.

•

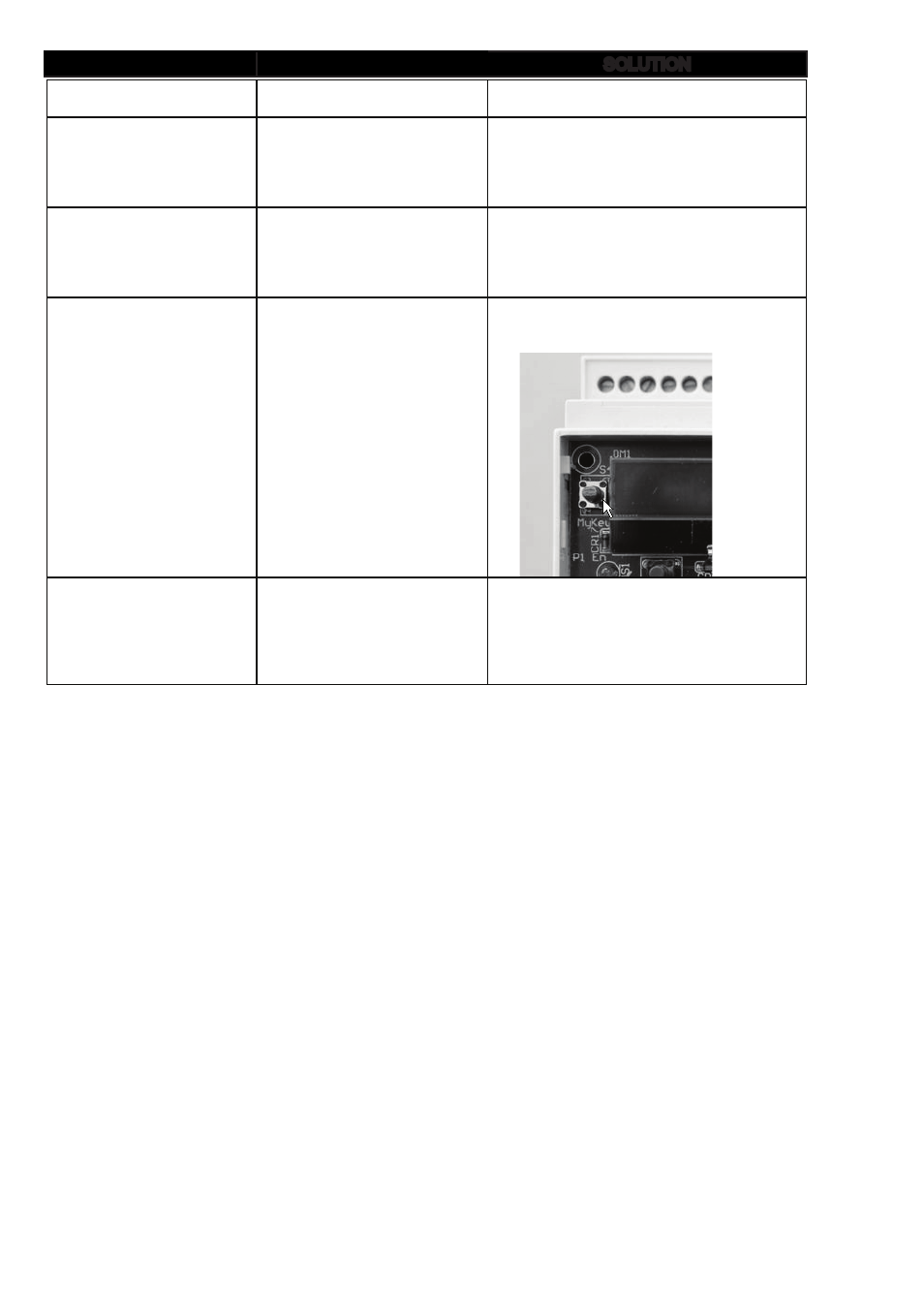

Press the “Commissioning Button” on the

PCB whilst powering up the system to

initialise the program

•

System Pressure not

displaying

•

Analogue circuits not

functional

•

There are 2 LED’s located on the front

top right of the PCB. One is for Power

which should be flashing – the other is for

indication that the analogue circuit is

operational. Solid light means OK- No

light means inoperative.

PROBLEM

CAUSE

SOLUTION

INSTALLATION NOTES

Here are some “GOLDEN RULES” in site installation that should be followed.

Site Installation

•

Select the site most shaded and out of direct sunlight. Heat is a VSD killer.

•

Allow the airflow from the fans to be unimpeded.

•

Always connect the motor earth directly to the earth within the VSD.

•

Inputs

•

Connect the shield to EARTH and one end only.

•

Never apply voltage to the Inputs.

•

Take care in running inputs for long distances.

•

The inputs use a 24VDC signal as the carrier voltage - use compliant sensors.

•

Outputs

•

5 amp maximum switching load.

•

Check the programming on each output before trying to troubleshoot.

•

Start-up

•

CHECK ROTATION CHECK ROTATION CHECK ROTATION CHECK ROTATION

All these items are site related