Davey Speedman Dual Pump Variable Speed Pump Control System User Manual

Page 50

50

CALIBRATION OF ANALOGUE SENSORS

The Speedman can accept most analogue signals from sensors and requires that a calibration routine be run

to set both SCALING and ZERO OFFSET of these sensors.

Go to the CONFIGURE Menu and press the Enter Key.

ZERO ERROR

The Zero Error routine should be done BEFORE using the “Adjust Pressure” screen.

The zero error offset is trimmed out on the “Transducer Zero” screen. Make sure there is no pressure in the

system or in the tube leading to the transducer.

Zeroing the transducer can be done two ways. Either via automatic method or manual method.

Automatic Method

On the “Transducer Zero” screen press ENTER to edit the data. Then press and hold both up and down

for 2 seconds then release. On the screen should read “Finding Zero – Please Wait”, this will take about

5-20 seconds depending on the value you have set for averaging. After it finishes it should show the value

0, if it shows 1 or VALUE TOO LOW, then a minor amount of fine tuning will be required. The fine tuning is

accomplished using the Manual Method Below, In short press the down button to decrease the value, and if

the screen shows “VALUE TOO LOW” press the UP button until zero appears.

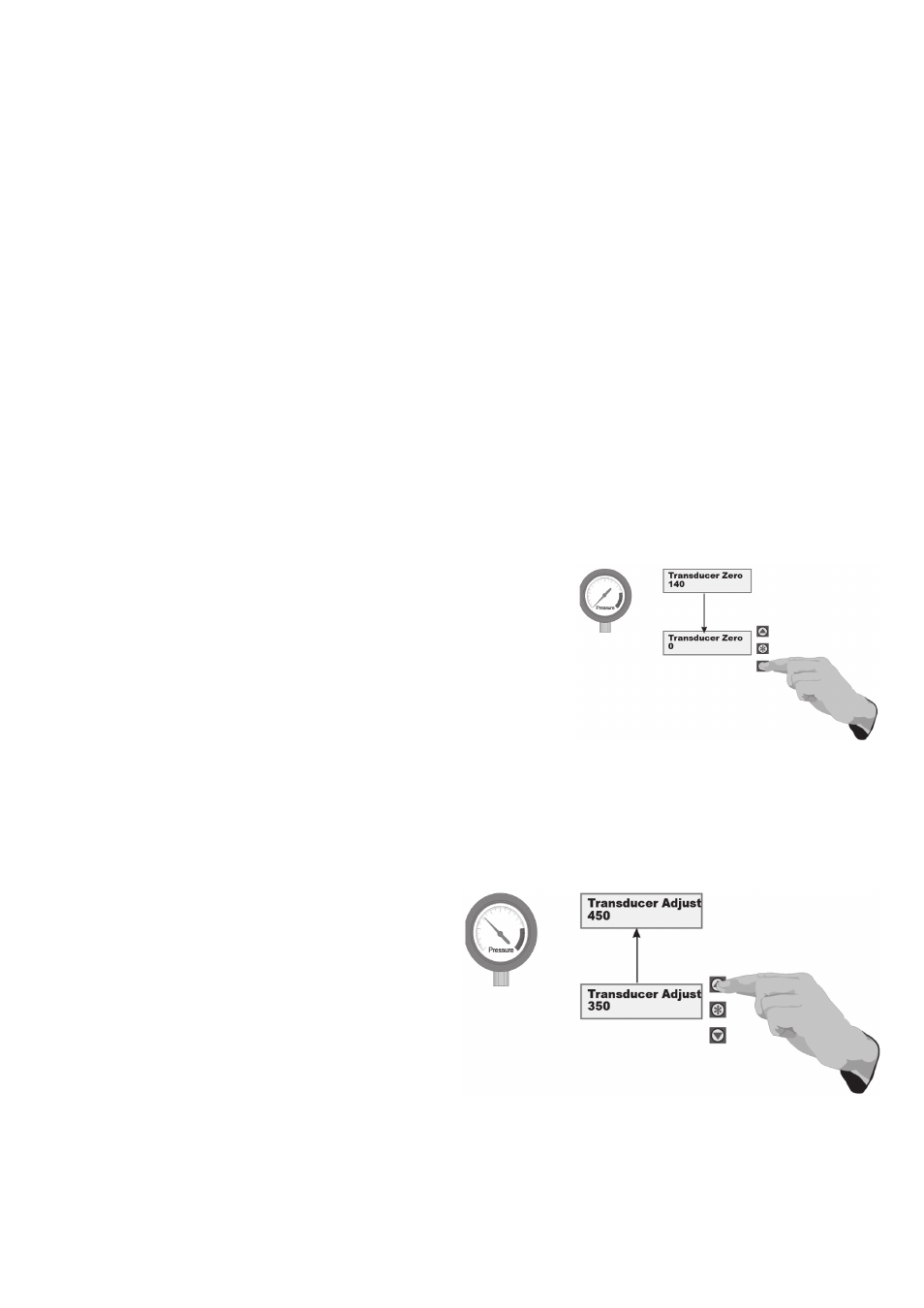

Manual Method

On the “Transducer Zero” screen press ENTER to edit the data

and then DOWN to make the reading go to “0”. Wait for 5 seconds

for the reading to stabilise. Take care when running this procedure

to reduce to the “zero” value slowly as the possibility of running past

is high.

The pressure readings are averaged so the readings can lag

behind the key presses. Always allow the system to stabilise prior

to completing this procedure.

If the value input is lower than Zero a message stating, “VALUE TOO LOW” will appear on the screen. Press

the UP key until a “zero” value appears.

Once completed, press ENTER again and back out of the menu to initiate a store of the “zero” value.

PRESSURE ADJUSTMENT

For this routine it is necessary to have a reference

pressure that can be used to compare the system

pressure to the pressure that the Speedman senses.

To calibrate the scaling for the analogue sensor apply

a pressure to the system and allow it to stabilise.

This can be done by manually starting one pump and

then closing the main isolation vale and shutting down

the pump. This should hold system pressure and

remove any fluctuations that are prevalent when

pumps are running.

The system pressure should be set at least two times higher than the standard operating pressure, as the

calibration routine works best with an end of scale reading.