Davey Speedman Dual Pump Variable Speed Pump Control System User Manual

Page 51

51

Go to the “Adjust Pressure” screen. The pressure on this screen should match the pressure on a pressure

gauge in the system. If it does not, press ENTER and then either UP or DOWN to move the displayed

pressure to match the gauge pressure.

There is a buffer that takes approximately 5 seconds to stabilise so wait for this period to make sure that the

reading is stable before accepting or editing the settings.

Once the readings match and are steady then the scaling is calibrated. Press ENTER again and back out of

the menu to initiate a store of the “Adjust Pressure” value.

FLOW METER ADJUSTMENT

Flow Meter Zero

The “Flow Meter Zero” adjusts the zero offset in the Flow Meter input. Make

sure there is zero flow in the system before attempting to zero the flow meter.

Be sure that the flow meter is connected to the relevant input.

Zeroing the flow meter can be done two ways. Either via automatic method or manual method.

Automatic Method

On the “Flow Meter Zero” screen press ENTER to edit the data. Then press and hold both up and down

for 2 seconds then release. On the screen should read “Finding Zero – Please Wait”, this will take about

5-20 seconds depending on the value you have set for averaging. After it finishes it should show the value

0, if it shows 1 or VALUE TOO LOW, then a minor amount of fine tuning will be required. The fine tuning is

accomplished using the Manual Method below. In short press the down button to decrease the value, and if the

screen shows “VALUE TOO LOW” press the UP button until zero appears.

Manual Method

With no flow rate in the system trim the display by pressing ENTER and then the UP or DOWN keys to set the

reading to “0”. Once calibrated press ENTER again and exit the CONFIGURE sub menu to store the value.

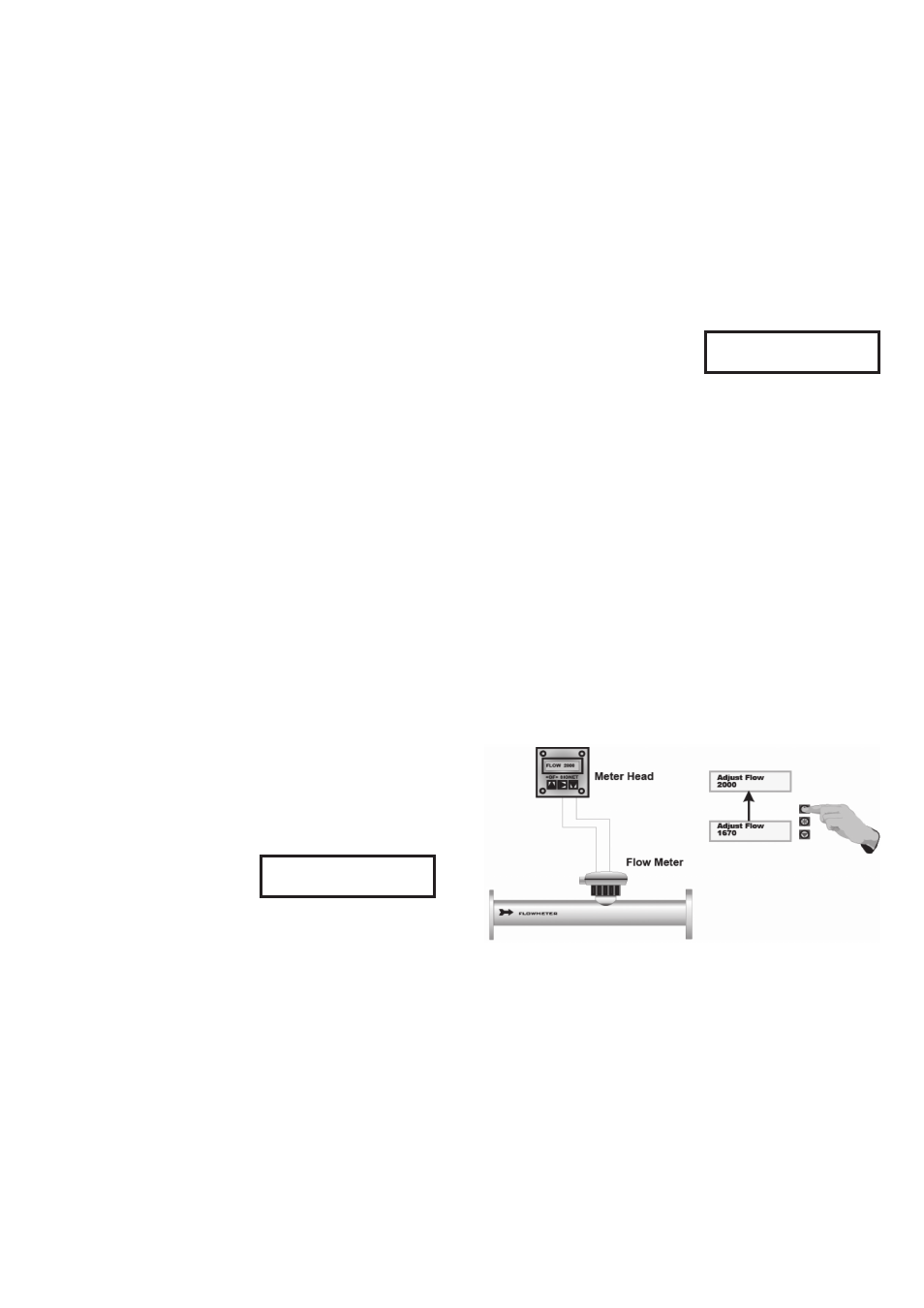

Adjust Flow

The calibration of the analogue sensors is

achieved by adjusting the Flow meter reading

on this screen to match a reading from the

Flow Meter output screen.

GENERAL

The basis for calibration is that the sensors have linear response. If the instrument being used has non-linear

response the system readings will be inaccurate.

The standard transducer used with the Speedman has linear characteristics and has temperature

compensation to eliminate transducer error over a wide temperature span. Standard transducers have an

accuracy of ± 0.5% under normal conditions.

It is recommended that in cases where the normal system pressure in excess of 80% of the maximum

pressure to consider a different range transducer. Pressure shock can damage a transducer and render it

unserviceable.

Flow Meter Zero

XXXXX /min

Adjust Flow

XXXXX /min