Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 55

<4. Piping>

4-6

IM 11M12A01-04E

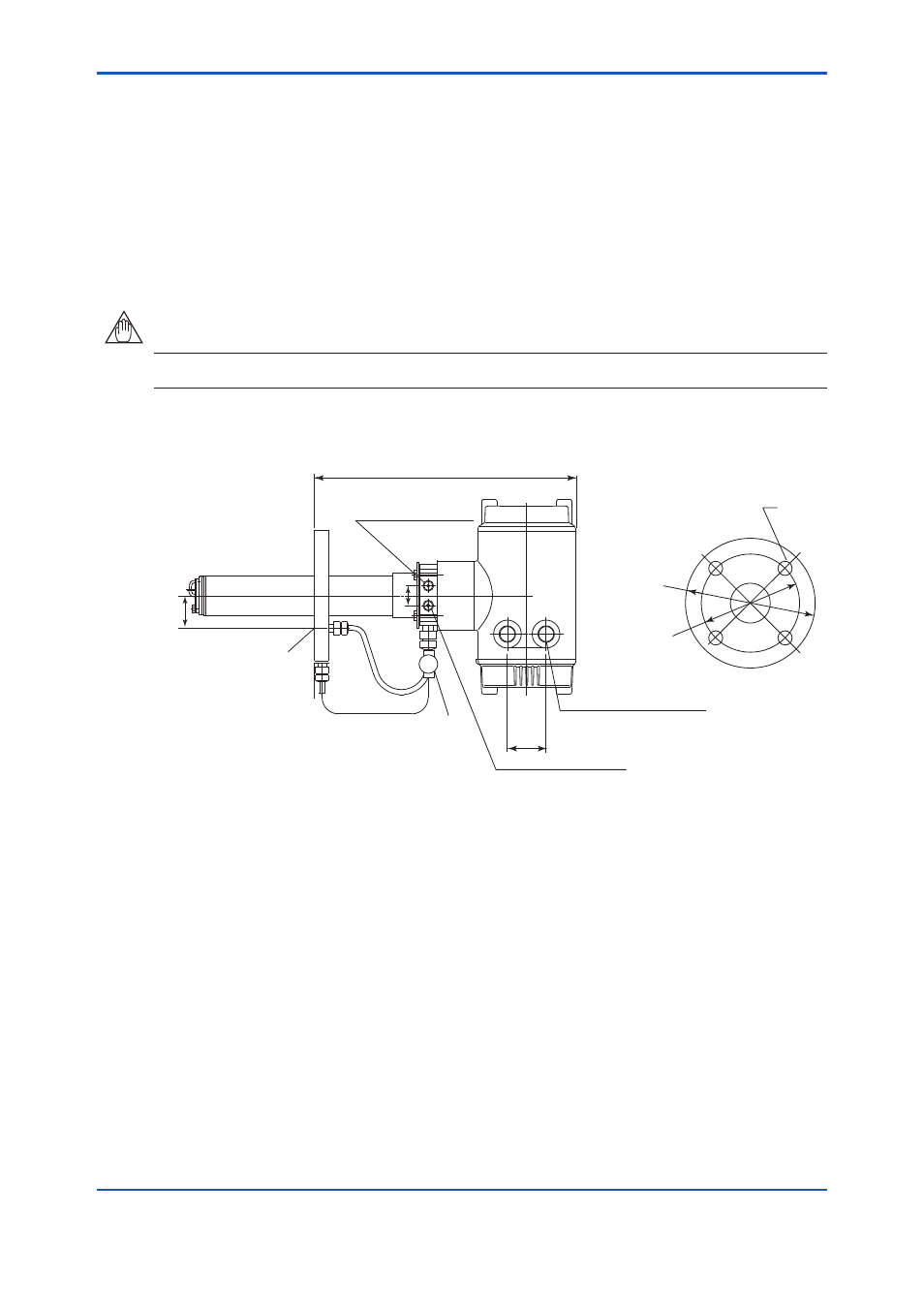

4.4 Piping for the Oxygen Analyzer with Pressure

Compensation

ZR202G-----P Oxygen Analyzer with pressure compensation may be used in System 2 and

System 3.

Use this style analyzer whenever the furnace pressure exceeds 5 kPa (see Note). Even if the furnace

pressure is high, the detector can measure by adjusting pressure of the probe with the furnace

pressure using instrument air. The inside pressure of the probe will be kept identical to the furnace

pressure by feeding instrument air at higher pressure than that in the furnace.

NOTE

The process gas pressure should not be subjected to rapid changes.

Unit: mm

The detector with pressure compensation is illustrated in Figure 4.12.

49

342±4

25

F4.12E.ai

ØB

ØA

C

*1

*1

*1

*1

*1

*1: Dimension may vary depending on the detector type.

Ensure that the flange gasket does not block off the reference gas outlet.

Where necessary, make a notch on the flange

Rc 1/4 or 1/4 NPT

(Reference gas inlet)

4-G1/2, 2-1/2 NPT or the like

(Wiring connection)

Rc1/4 or 1/4NPT

(Calibration gas inlet)

Stop valve

Reference gas outlet

Flange

PIPING

PIPING

Figure 4.12

Oxygen Analyzer with Pressure Compensation

Ensure that the furnace gas does not flow into the probe.

Valve operation

1. For safety, stop the furnace that the detector is to be installed in. If furnace internal pressure is

high, this is especially dangerous.

2. Before starting instrument air flow, completely shut the stop valve in front of the reference gas

outlet.

3. Check that the reference gas outlet is not blocked by a flange gasket or the like.