3 piping for the reference gas, 3 piping for system 3, Piping for the reference gas -4 – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 53: Piping for system 3 -4

<4. Piping>

4-4

IM 11M12A01-04E

F4.8E.ai

Stop valve or check valve

Piping for the reference gas

6mm (O.D.) by 4mm (I.D.)

stainless steel pipe

Piping for the calibration gas

6mm (O.D.) by 4mm (I.D.)

stainless steel pipe

Figure 4.8

Piping for the Calibration Gas Inlet

4.2.3 Piping for the Reference Gas

Reference gas piping is required between the air source (instrument air) and the flow setting unit, and

between the flow setting unit and the analyzer.

Insert the air set next to the flow setting unit in the piping between the air source and the flow setting

unit.

Use a 6mm (O.D.) x 4mm (I.D.) (or nominal size 1/4 inches) stainless steel pipe between the flow

setting unit and the analyzer.

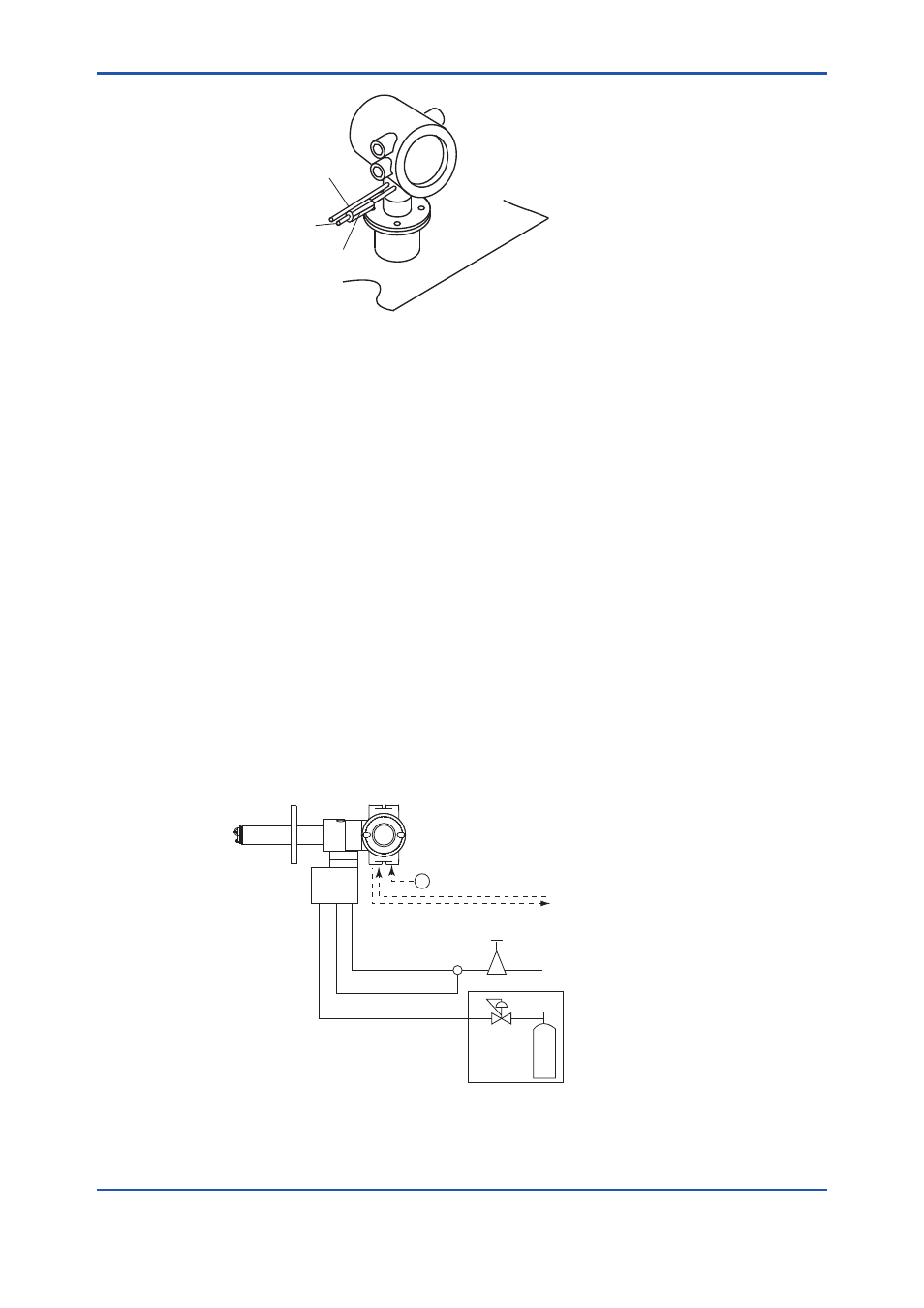

4.3 Piping for System 3

Piping in System 3 is illustrated in Figure 4.9. In System 3, calibration is automated; however, the

piping is basically the same as that of System 2. Refer to Section 4.2.

Adjust secondary pressure of both the air set and the zero gas regulator so that these two pressures

are approximately the same. The flow rate of zero and span gases (normally instrument air) are set

by a individual needle valve. After installation and wiring, check zero gas calibration contact output

(see Sec. 7.9.2), and adjust zero gas regulator and calibration gas needle valve so that zero gas flow

is within the permitted range. Next check span gas calibration contact output and adjust air set so that

span gas flow is within the permitted range.

~

100 to 240 V AC

Automatic Calibration Unit

Reference gas

Calibration gas (Zero)

Contact input

Analog output, contact output

Digital output (HART)

Air Set

Instrument air

Calibration gas unit case

Pressure

regulator

Zero gas cylinder

ZR202G Integrated type Zirconia Oxygen Analyzer

with automatic calibration

F1.3E.ai

Span gas

ZR20H

Note:

The installation temperature limits range for integrated type analyzer is -20 to 55°C.

Figure 4.9

Piping for System 3