1 piping parts for system 1, 2 piping for the calibration gas, 3 piping for the reference gas – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 51: Piping parts for system 1 -2, Piping for the calibration gas -2, Piping for the reference gas -2

<4. Piping>

4-2

IM 11M12A01-04E

4.1.1 Piping Parts for System 1

Check that the parts listed in Table 4.1 are provided.

Table 4.1

Piping Parts

Equipment

Piping location

Parts Name

Description

Oxygen Analyzer Calibration gas inlet Stop valve

(L9852CB or G7016XH) recommended by

YOKOGAWA

Nipple *

Rc1/4 or 1/4 NPT

General parts

Joint for tube connection Rc1/4 (1/4NPT) for a

6x4mm soft tube

General parts

Reference gas inlet (Sealed up)

(when piping is required, refer to Section 4.1.3)

Note: Parts with marking * are used when required.

General parts can be found on the local market.

4.1.2 Piping for the Calibration Gas

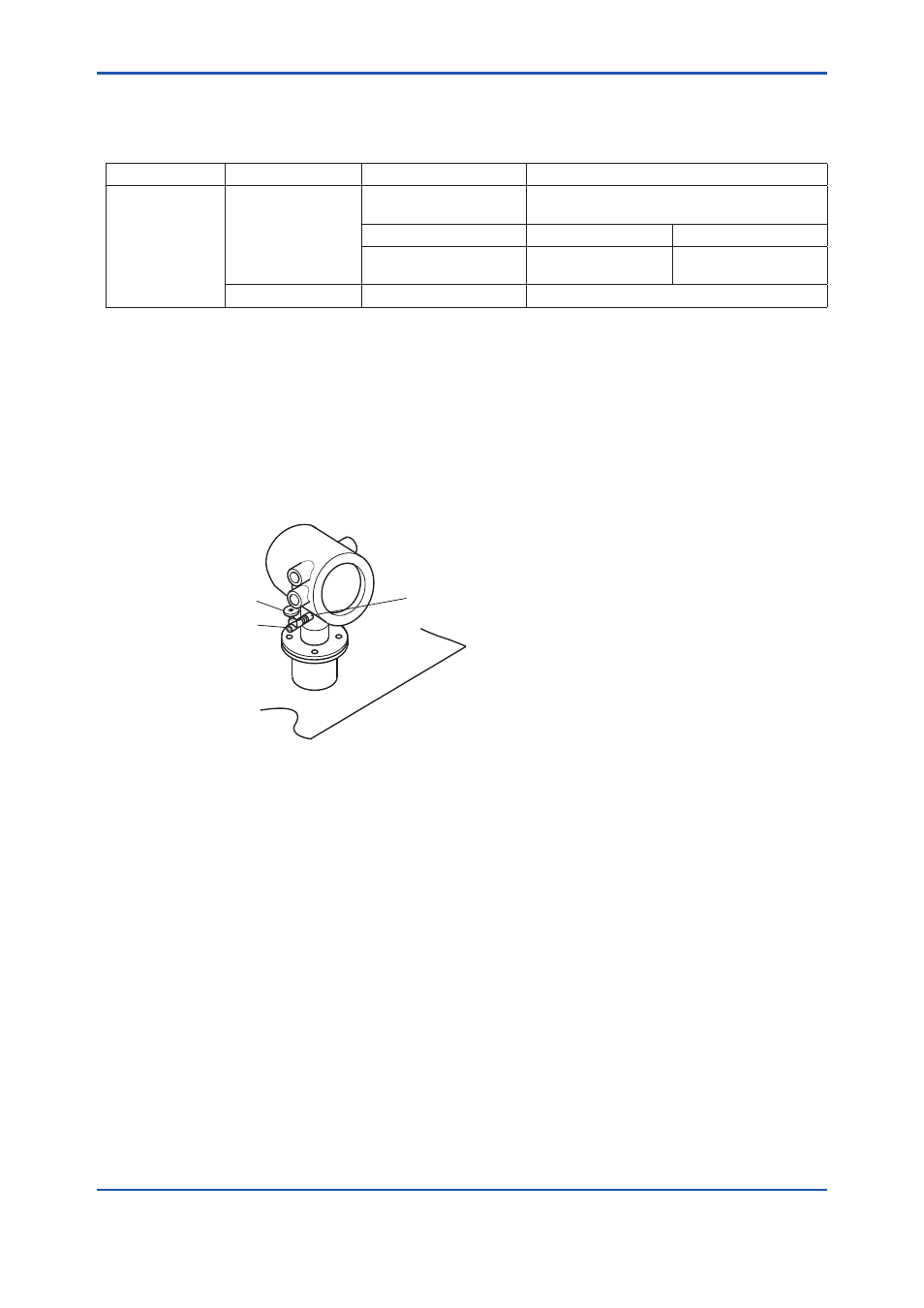

When carrying out calibration, connect the piping (6(O.D) x 4(I.D.) mm tube) from the standard gas

unit to the calibration gas inlet of the oxygen analyzer. Mount the stop valve (of a quality specified by

YOKOGAWA) through a nipple (found on the local market) as illustrated in Figure 4.2, and mount a

joint (also found on the local market) at the stop valve tip. (The stop valve may be mounted on the

equipment when the oxygen analyzer is shipped.)

Note: Mount the stop valve in the vicinity of the equipment.

F4.2E.ai

Stop valve

Tube connection

joint

Nipple

Figure 4.2

Piping for the Calibration Gas Inlet

4.1.3 Piping for the Reference Gas

• Normally, no piping is required for the reference gas inlet when the equipment applies natural

convection for reference gas (models ZR202G-----C). Leave the plug as it is. If the air

around the probe is polluted and the necessary oxygen concentration (21 vol%O

2

) cannot be

obtained, make instrument air piping as in Section 4.2, System 2.

• When the equipment uses instrument air for the reference gas, piping is required as described in

Section 4.2, System 2 (models ZR202G-----E or P).