Model and codes – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 25

<2. Specifications>

2-6

IM 11M12A01-04E

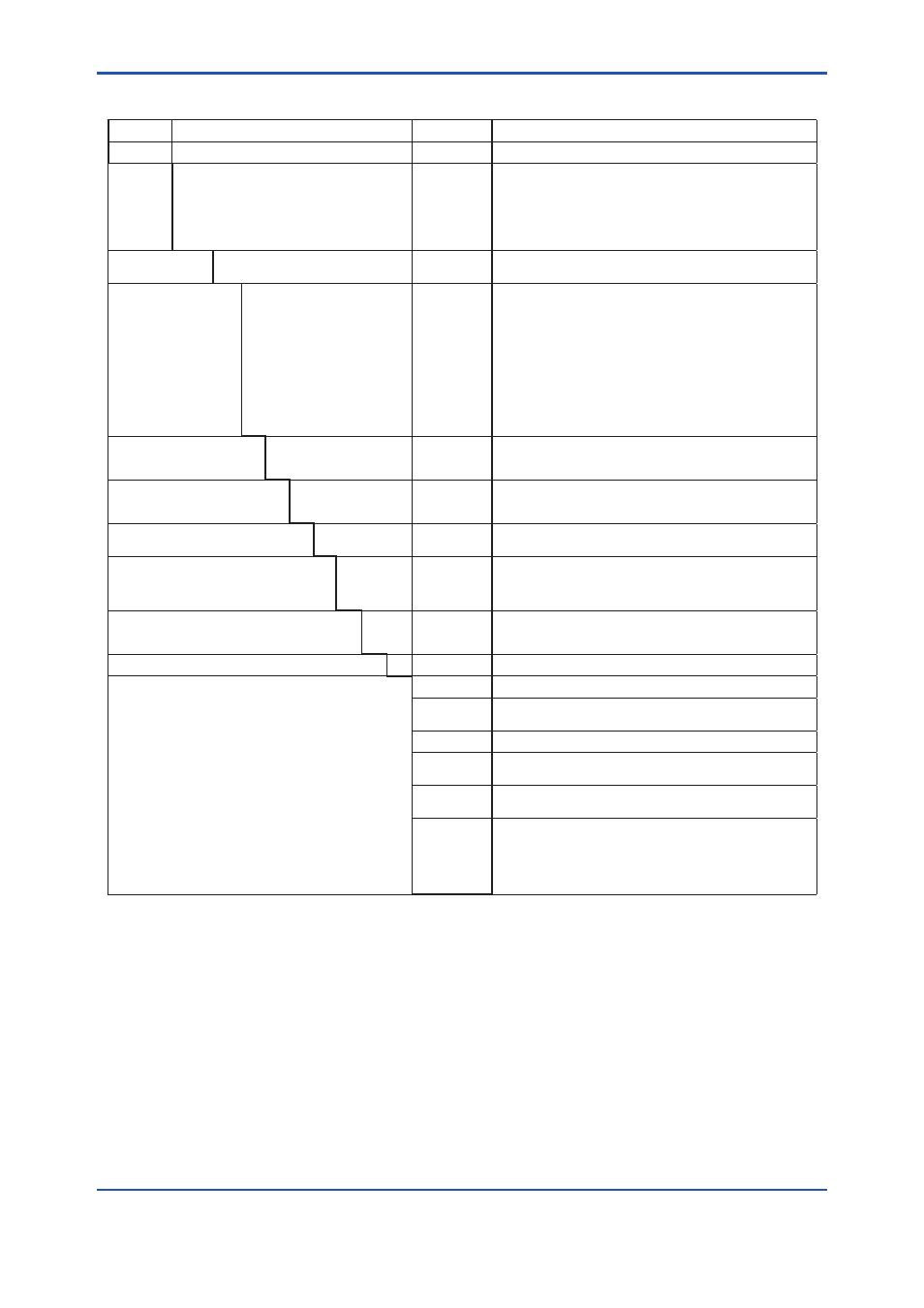

Model and Codes

Model

Suffix code

Option code

Description

ZR202G

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Integrated type Zirconia Oxygen Analyzer

Length

-040

-070

-100

-150

-200

-250

-300

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

0.4 m

0.7 m

1.0 m

1.5 m

2.0 m

2.5 m (*1)

3.0 m (*1)

Wetted material

-S

-C

- - - - - - - - - -

- - - - - - - - - -

SUS316

Stainless steel with Inconel calibration gas tube (*8)

Flange

(*2)

-A

-B

-C

-E

-F

-G

-K

-L

-M

-P

-R

-S

-W

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

ANSI Class 150 2 RF SUS304

ANSI Class 150 3 RF SUS304

ANSI Class 150 4 RF SUS304

DIN PN10 DN50 A SUS304

DIN PN10 DN80 A SUS304

DIN PN10 DN100 A SUS304

JIS 5K 65 FF SUS304

JIS 10K 65 FF SUS304

JIS 10K 80 FF SUS304

JIS 10K 100 FF SUS304

JPI Class 150 4 RF SUS304

JPI Class 150 3 RF SUS304

Westinghouse

Auto Calibration

-N

-A

-B

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

Not required

Horizontal mounting (*6)

Vertical mounting (*6)

Reference gas

-C

-E

-P

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

Natural convection

External connection (Instrument air) (*9)

Pressure compensated (*9)

Gas Thread

-R

-T

- - - - - - - - - -

- - - - - - - - - -

Rc 1/4

1/4 NPT (Female)

Connection box thread

-P

-G

-M

-T

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

G1/2

Pg13.5

M20x1.5 mm

1/2NPT

Instruction manual

-J

-E

-C

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

Japanese

English

Chinese

--

-A - - - - - - - - - -

Always -A

Options

Valves

Tag plates

NAMUR NE43 compliant

/C

Inconel bolt (*3)

/CV

/SV

Check valve (*4)

Stop valve (*4)

/H

Hood (*7)

/F1

/F2

Dust Filter

Dust Guard Protector

/SCT

/PT

Stainless steel tag plate (*5)

Printed tag plate (*5)

/C2

/C3

Failure alarm down-scale:

Output status at CPU failure and hardware error is 3.6 mA or less

(*10)

Failure alarm up-scale:

Output status at CPU failure and hardware error is 21.0 mA or more

(*10)

*1

For the horizontally installed probe whose insertion length is 2.5 m or more, use the Probe Protector. Be sure to specify

ZO21R-L-200-. Specify the flange suffix code either -C or -K.

*2

The thickness of the flange depends on its dimensions.

*3

Inconel probe bolts and U shape pipe are used. Use this option for high temperature use (ranging from 600 to 700°C).

*4

Specify either /CV or /SV option code.

*5

Specify either /SCT or /PT option code.

*6

No need to specify the option codes, /CV and /SV, since the check valves are provided with the Automatic Calibration Unit.

Automatic calibration cannot be used when natural convection is selected as reference gas.

*7

Sun shield hood is still effective even if scratched. Hood is necessary for outdoor installation out of sun shield roof.

*8

Recommended if sample gas contains corrosive gas like chlorine.

*9

Piping for reference gas must be installed to supply reference gas constantly at a specified flow rate.

*10 Output signal limits: 3.8 to 20.5 mA. Specify either /C2 or /C3 option code.