Installation, Warning, A-20 – Lincoln Electric P709 GUARDIAN CONTROL SOLUTIONS User Manual

Page 27: Electrical connection, Compressed air connection

A-20

INSTALLATION

GUARDIAN CONTROL™ SOLUTIONS

A-20

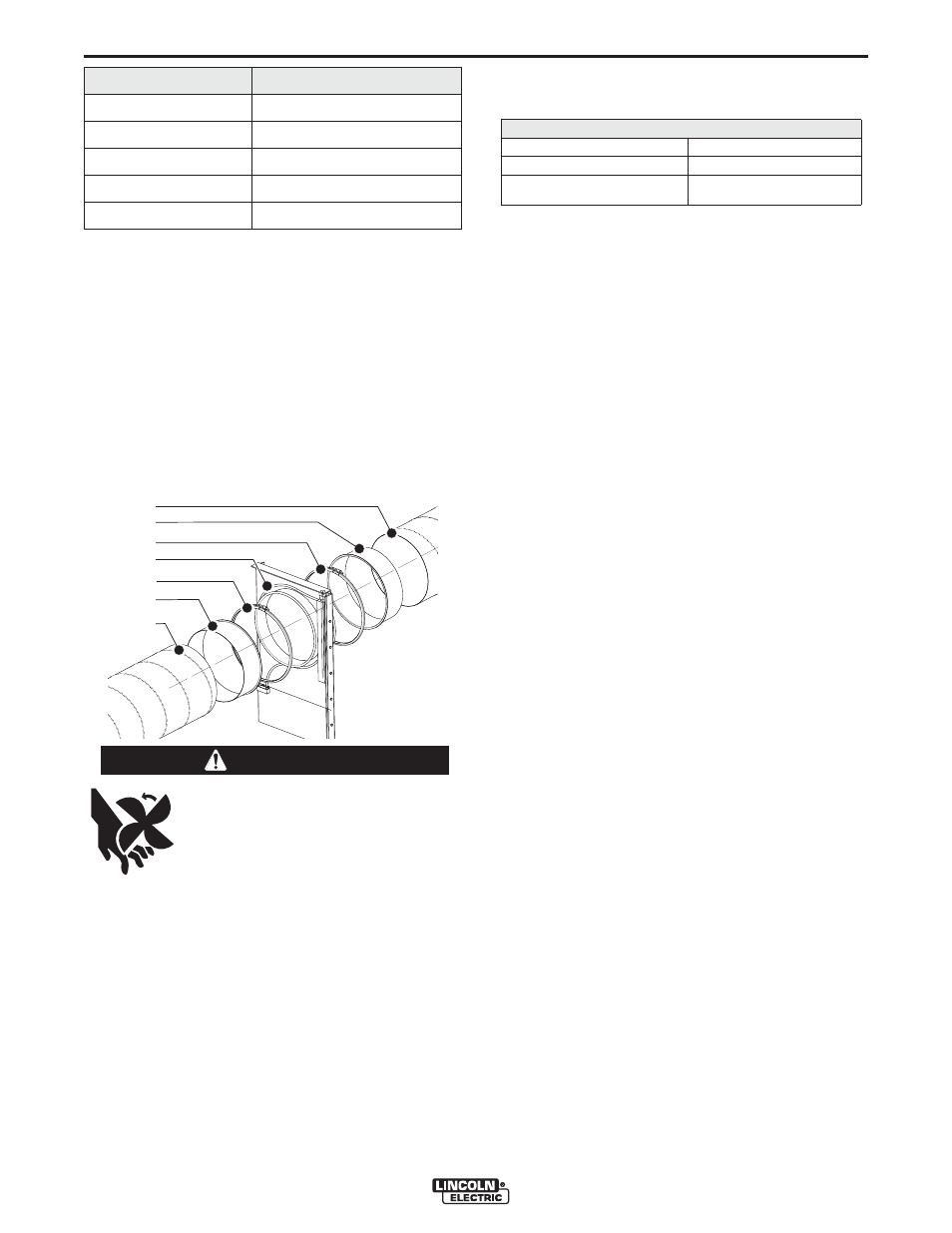

4. Slide a connection flange (B) into both duct ends

(A).

5. Place the sliding valve (D in between and fasten it

using the quick connect couplings (C).

6. Fasten the connection flanges using self-tapping

screws.

NOTE: The valves must be mounted straight and

without tension on the shell/housing to guar-

antee airtightness and to avoid noise from air-

flow.

ELECTRICAL CONNECTION

To be sourced locally:

• Connection wire: 5 x 20 AWG cable

Wiring

1. Connect the sliding valves to the system control

panel in accordance with the Electrical Wiring

Diagram.

2. Connect the reed contacts to the system control

panel in accordance with the Electrical Wiring

Diagram.

COMPRESSED AIR CONNECTION

1. Connect the sliding valves to compressed air source

per the Pneumatic Diagram.

Setting closing speed of the sliding valves

The closing speed of the valves is set by the air pres-

sure.

1. Set the closing speed of the valves to 4-5 seconds

by adjusting the air pressure to 5 BAR.

Do not set the valves to faster than 4 seconds. If there

is a fire alarm, the fan is switched off and the sliding

valves are closed. The 4 seconds gives the fan enough

time to reduce speed and prevents damage to the duct

by negative pressure. Do not select speeds slower

than 5 seconds, since the Flame Guardian™ modules

are activated 5 seconds after the fire alarm.

Post installation checks

• Check electrical connections.

• Check pneumatic connections.

• Check that nuts and bolts are secure.

Moving parts can cause injury.

If valve is mounted in an accessible

area, provide shroud and warning

label to prevent access.

-----------------------------------------------------------------------

WARNING

FIGURE A.14

B

A

B

A

C

D

C

Compressed air specifications

Compressed air connection

Recommended operational pressure

4-5 bar (max. 9 bar)

o

t

g

n

i

d

r

o

c

c

a

e

e

r

f

-

l

i

o

d

n

a

y

r

d

y

t

i

l

a

u

Q

ISO 8573-3 class 6

6 mm

Type of sliding valve

Duct length to be removed

.

n

i

4

.

0

-

/

+

.

n

i

6

.

1

1

0

1

-

V

S

.

n

i

4

.

0

-

/

+

.

n

i

6

.

1

1

2

1

-

V

S

.

n

i

4

.

0

-

/

+

.

n

i

6

.

1

1

6

1

-

V

S

.

n

i

4

.

0

-

/

+

.

n

i

0

.

5

1

0

2

-

V

S

.

n

i

4

.

0

-

/

+

.

n

i

0

.

5

1

4

2

-

V

S

FIGURE A.15