IAI America RCA2-SD4N User Manual

Page 57

8. Installation

49

8.2.3 Installation of Flange

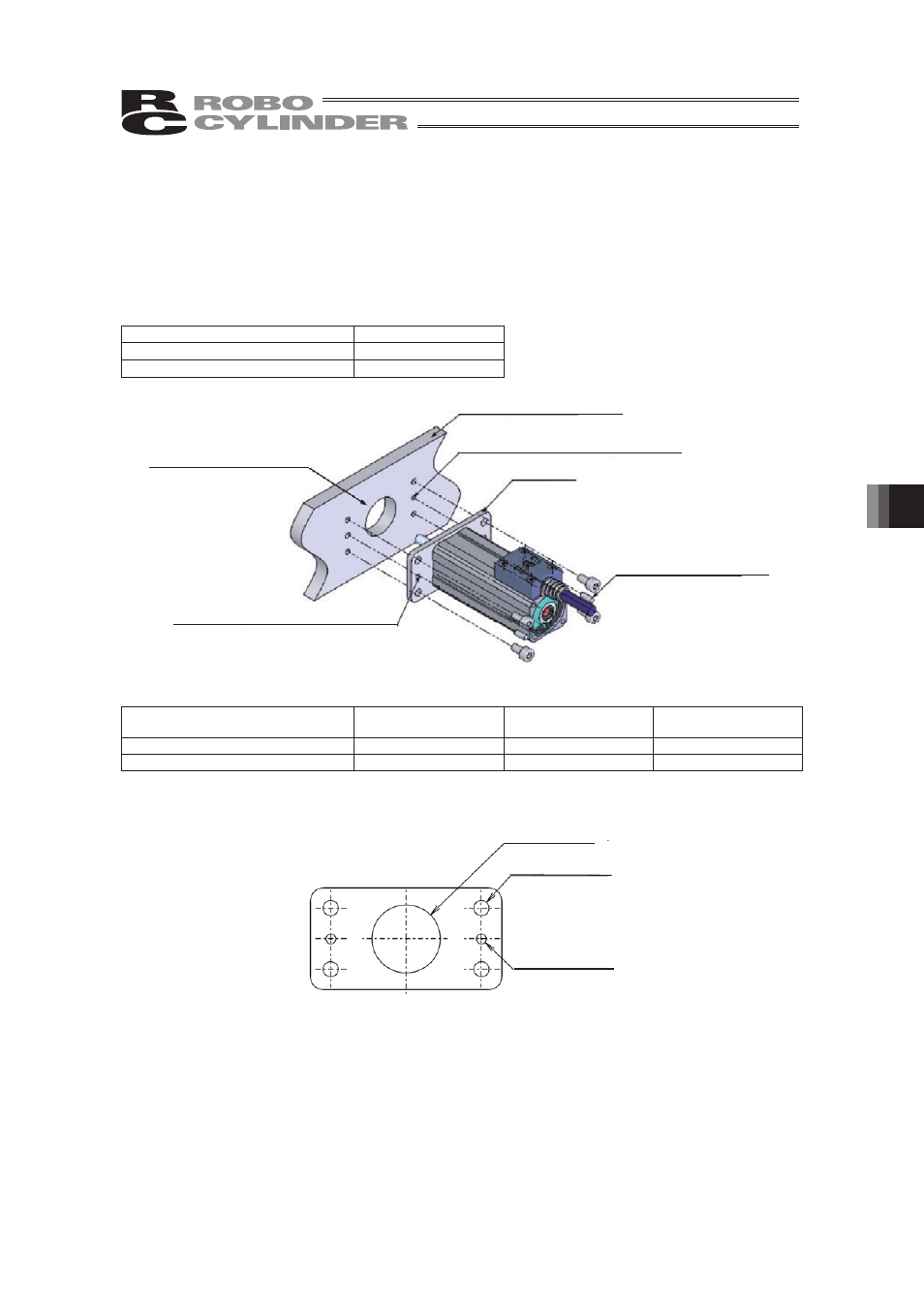

Provide a flange-shaped sheet and install the actuator onto this sheet from the back.

• Use the nut on the actuator rod to install the actuator onto the flange.

• Secure the flange with the actuator mounting plate using screws.

If positioning is required, insert positioning pins.

(Note) For the actuator mounting hole in the actuator mounting plate, provide a hole larger than

the dimension of the nut so as to provide a clearance for the nut.

Type

Nut diameter

RN3NA, RN3N (Lead screw, ball screw)

I

34

RN4NA, RN4N (Lead screw, ball screw)

I

30.8

Actuator mounting hole

Actuator mounting plate

Positioning pin hole (2 locations)

Positioning pin hole (2 locations)

Flange

Positioning pin (2 pcs)

Installation of actuator and flange

Type

M

Width across flats

Maximum tightening

torque

RN3NA, RN3N (Lead screw, ball screw)

M20 × 1.0

29

49.4N·m

RN4NA, RN4N (Lead screw, ball screw)

M24 × 1.0

32

76.8N·m

(Reference drawing of flange)

4-φ4.5 through

(M4)

2-reamed hole

φ

20 or 24HB