IAI America RCA2-SD4N User Manual

Page 18

10

8. Transportation

8.1 Handling a Single Actuator

Please adhere to the following when handling a single actuator.

8.1.1 Handling the Packed Unit

Unless otherwise specified, the actuator is shipped with each axis packaged separately.

• Do not damage or drop. The package is not applied with any special treatment that enables it to

resist an impact caused by a drop or crash.

• Transport a heavy package with at least more than two operators. Consider an appropriate

method for transportation.

• Keep the unit in horizontal orientation when placing it on the ground or transporting. Follow the

instruction if there is any for the packaging condition.

• Do not step or sit on the package.

• Do not put any load that may cause a deformation or breakage of the package.

8.1.2 Handling the Actuator After Unpacking

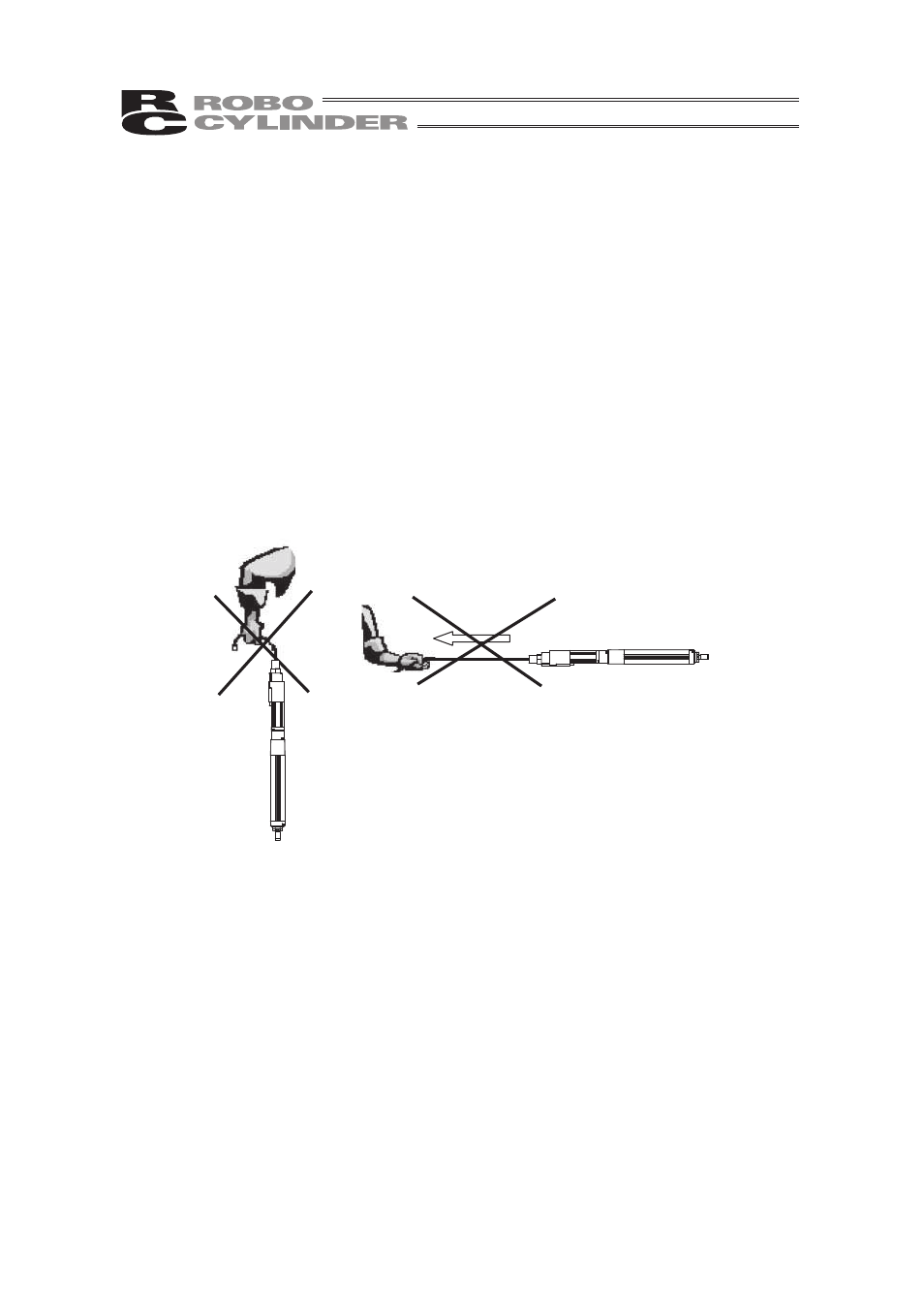

• Do not carry an actuator by a cable or attempt to move it by pulling the cable.

• Hold the body base when transporting the actuator.

• Be careful not to bump the actuator into anything when moving it.

• Do not apply an excessive force to each part of the actuator. In particular, prevent the motor unit

and rear bracket from receiving an unnecessary force.

Supplement) For the names of each part of the actuator, refer to 1, "Part Names".

8.2 Handling the Actuator Assembly

• When carrying the actuator, exercise caution not to bump it against nearby objects or structures.

• Secure the sliders to prevent sudden movement during transport.

• If any end of the actuator is overhanging, secure it properly to avoid significant movement due to

external vibration.

• When transporting the assembly without the ends of the actuators fastened, do not subject the

assembly to an impact of 0.3 G or more.

• When suspending the mechanical equipment (system) with ropes, avoid applying force to

actuator, connector box, etc. Also, avoid the cables being pinched or caused an excessive

deformation.