Wheel cleaning, Chuck cleaning, General maintenance – Darex XPS-16 Operating Instructions User Manual

Page 80

80

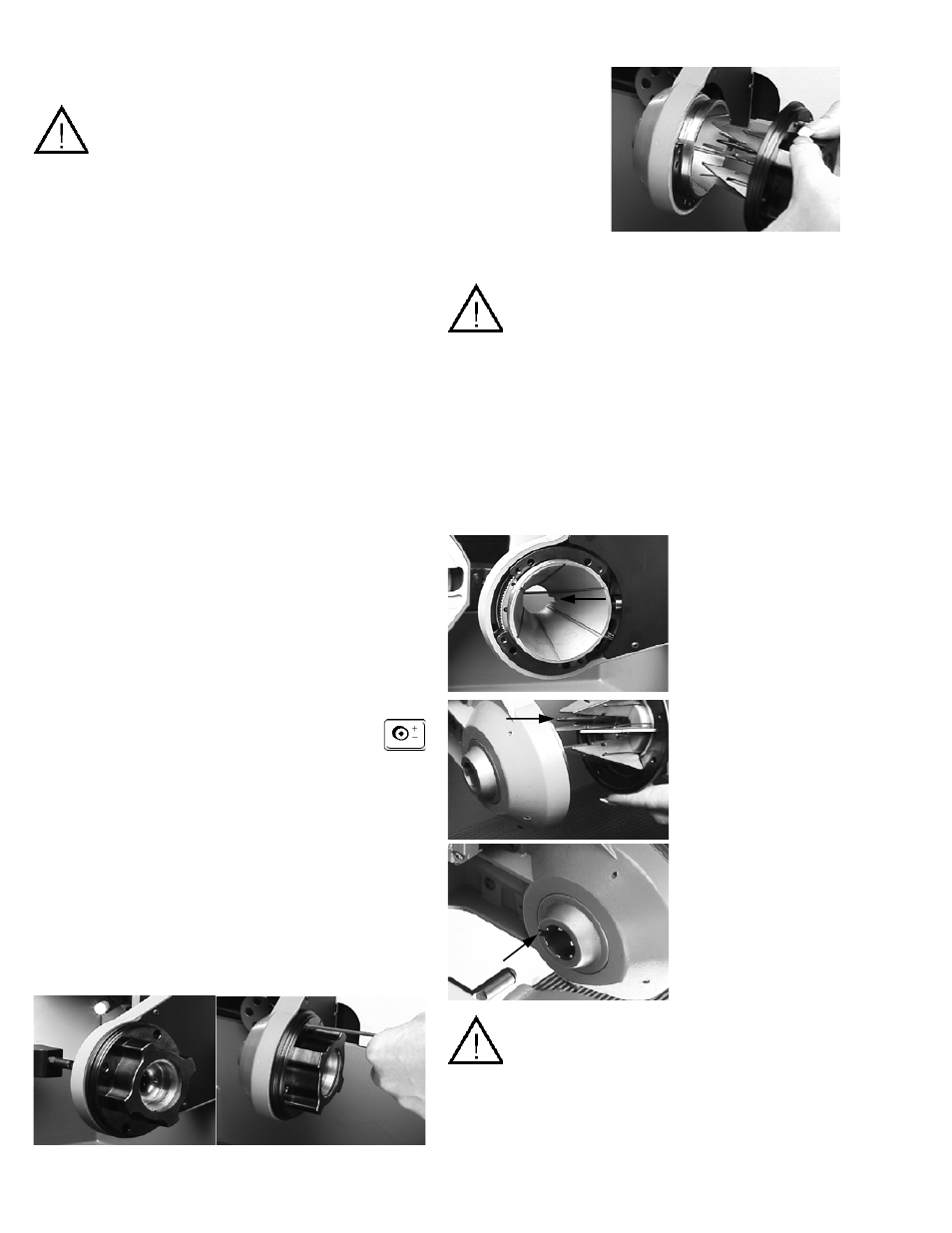

Wheel cleaning:

Always clean a brand new wheel be-

fore using. Wheels are packaged in

rust preventative oil and will load up

if not cleaned before grinding.

These wheels are maintenance free from truing

and dressing but will need cleaned periodically.

•

Remove the wheel from the unit.

•

Saturate the wheel with any type of oil-less

solvent, such as Automotive Brake Cleaner.

•

Use a soft bristle brush and lightly brush the

saturated wheel loosening the impacted grind-

ing particles.

•

Re-saturate the wheel to flush out any loos-

ened debris.

NOTE: If after cleaning the wheel,

(page 57)

the drills still discolor or burn, the wheel life

may be exhausted and the wheel will need

replaced.

Refer to page 57

for wheel change

instructions.

After a wheel change, verify and/or recali-

brate Material Take Off (MTO):

1. Use a 3/8 HSS standard twist drill, measure

the length of drill before sharpening.

2. Call up the Darex #1 file and sharpen a drill.

3.

After sharpening the drill, measure the drills

new length. MTO should be approxi-

mately .005-.007.

4.

If incorrect, adjust using Grinding

Wheel Adjustment Screen Selector

Refer to page 28 & 59

Chuck cleaning:

Push the emergency stop button, unplug unit from

power supply and use a “LOCK OUT” “TAG OUT”

procedure.

•

Open chuck jaw assembly to its largest capac-

ity range. Use a 3mm hex key wrench to re-

move the 4; 4mm Allen head cap screws from

the chuck knob.

•

The chuck jaw

assembly can

now be re-

moved through

the back of the

chuck spindle

assembly.

•

Brush away any grinding residue.

DO NOT REMOVE JAWS FROM

SPRINGS OR SPRINGS FROM SPIN-

DLE INSERT. JAWS ARE POSITIONED AND

THEN GROUND TO MATCH THE SPINDLE

CONE HOUSING. BY REMOVING, YOU MAY

COMPROMISE THE PRECISION OF THE

CHUCK!

TO REINSTALL:

•

Reinstall in reverse order, making sure the di-

ameter detect rod is oriented in spindle cor-

rectly.

If diameter detector rod is reinstalled im-

properly, damage to rod will occur.

•

After chuck jaw assembly is properly replaced

and before the 4mm bolts are in place, open

or close the chuck knob until the bolt hole pat-

General Maintenance