Recalibrate material take off, How to change a wheel, Wheel information – Darex XPS-16 Operating Instructions User Manual

Page 58

58

Wheel Information

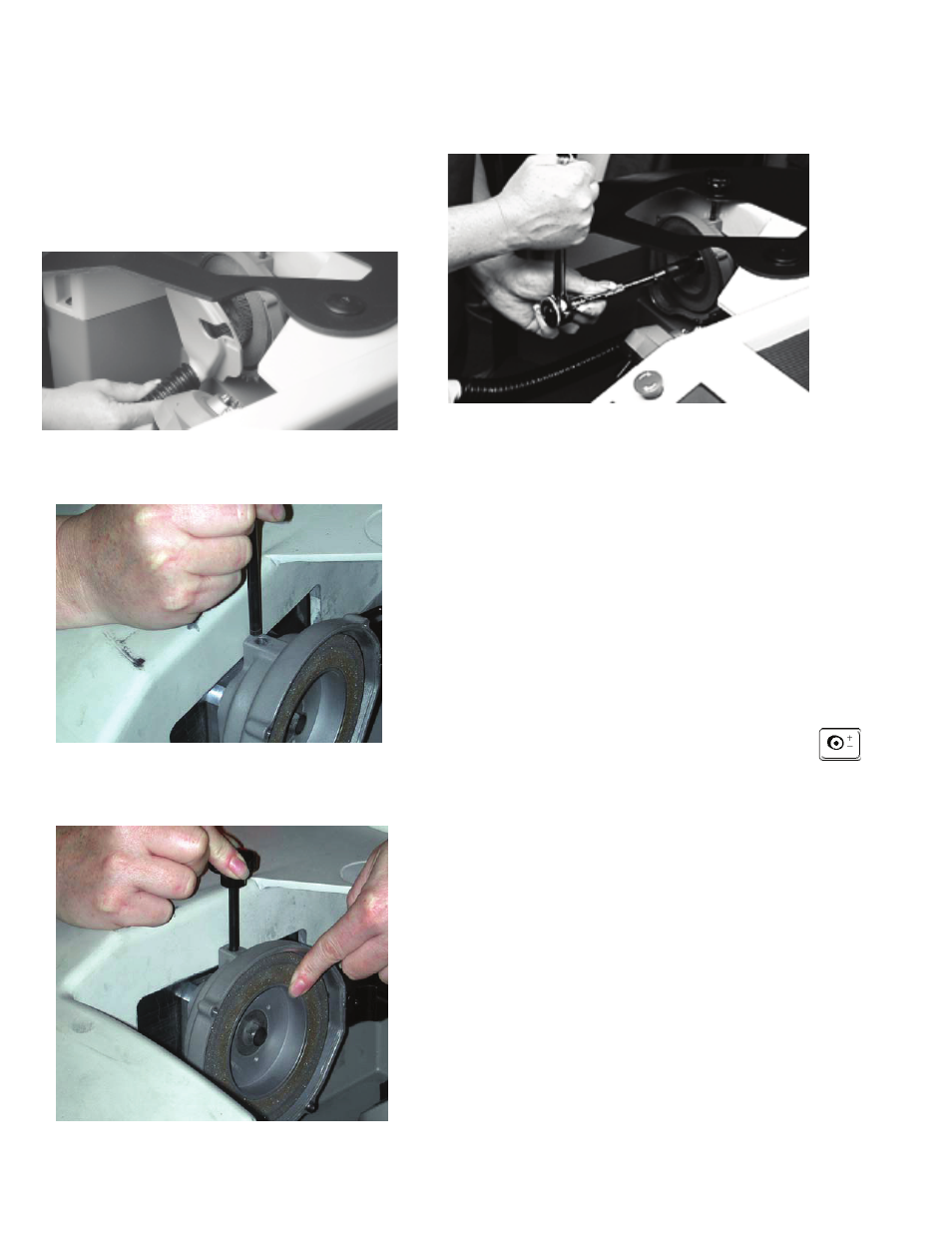

7. Using a ½ inch socket wrench, loosen wheel

retainer bolt in the counterclockwise direction until

wheel is free of the spindle.

8. Repeat steps in reverse to install new wheel.

Tighten to 12 lbs/per foot.

When changing from a CBN to Diamond or

vise versa, it’s a good idea to write the

wheel offsets on the back of the wheel be-

fore adjusting the offsets to the new wheel.

Recalibrate Material Take Off

•

After a wheel change, verify and/or recalibrate

Material Take Off:

1. Use a 3/8 HSS standard twist drill, measure

the length of drill before sharpening.

2. Using the Darex #1 File sharpen the drill.

3. After sharpening the drill, measure the drills

new length. MTO should be approxi-

mately .005-.007.

4. If incorrect, adjust using Grinding Wheel

Offset Screen Selector

Refer to information

on page 59.

HOW TO CHANGE A WHEEL

1. Push the emergency stop button, unplug unit

from power supply and use a “LOCK OUT”

“TAG OUT” procedure.

2. Remove Guard door cover.

3. Remove thumbscrews from cover.

4. Pull the wheel guard cover away from wheel,

leaving the vacuum tube attached.

5. Insert spindle lock pin through access hole

located on top of wheel guard casting.

6.

Rotate spindle until spindle lock pin engages.